One of the main factors responsible for the failure of electronic assemblies is the effect of moisture, for example through humidity. The classic protection against moisture-related failures is coating with protective lacquers. When electronic assemblies are used, the protective coatings are more or less regularly exposed to moisture. This always raises the question for the user as to how these protective coatings can be tested for their suitability. From the customer's point of view, it would ideally be desirable to determine a clearly ascertainable parameter from which the quality of the protective coating could be derived.

Customers are often very interested in knowing or determining the water vapor permeability or water absorption and using this information to determine the suitability or unsuitability of a coating to protect electronics from moisture.

Apart from testing water absorption and water vapor permeability, numerous other test methods such as harmful gas tests or iodine vapor tests are commonly used to make a statement about the functionality of a coating against moisture.

In the following, the main focus will be on the comparison of water vapor permeability with other tests and the correlation of the resulting results. Conversely, it could also be assumed that the measurement of a value provides a comprehensive statement on the functionality of the protective coating.

Coating materials have both different water absorption and water vapor permeability, which can have an effect on

- mechanical properties

- adhesion strength

- glass transition temperature

- Light and weather resistance

- corrosion protection properties

- Electrical insulation properties

Moisture and water are among the most damaging influences on coating materials. The water vapor permeability and also the moisture absorption of polymers - of coatings - is not in itself an absolute exclusion criterion for use as an insulating material. All polymers are permeable to water vapor to a certain extent; this permeability is referred to as permeation. Similarly, all polymers absorb moisture, a process known as absorption.

Both parameters - water absorption and water vapor permeability - can be determined using suitable measurement methods. In the case of water absorption, a percentage value is obtained as a parameter; in the case of water vapor permeability, a mass value per area and layer thickness is obtained.

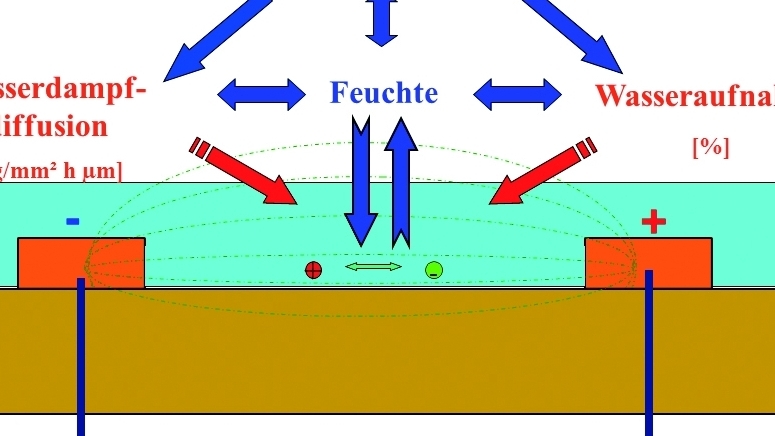

Both key figures are not absolute parameters, but are in turn dependent on the temperature, the prevailing relative humidity (actually the water vapor partial pressure) or the presence of condensed water on the coating film. The relationships are shown schematically in Figure 1; the influences of given contaminations are not taken into account in this diagram. Fig. 1: Schematic correlation of water vapour diffusion and water absorption with the climatic conditions

Fig. 1: Schematic correlation of water vapour diffusion and water absorption with the climatic conditions

Knowledge of these parameters provides information about the water balance of a coating material, but not about the relevant effects of the water balance on the electrical insulation properties, i.e. the movement of the electrical charge carriers in the polymer film. Also, the parameters of water vapor permeability and water absorption cannot be considered independently of each other. Water vapor diffusion can increase significantly with increasing water absorption.

Exemplary results of the water vapor permeation of some Elpeguard protective coatings:

- Twin-Cure DSL 1600 E-FLZ/75: 240 g/(m²*d) at 90 µm film thickness

- ELPEGUARD SL 1307 FLZ/232: 37 g/(m²*d) at 60 µm film thickness

- ELPEGUARD SL 9407 FLZ: 32 g/(m²*d) at 100 µm layer thickness

- ELPEGUARD UTC 1507 FLZ: 25 g/(m²*d) at 60 µm layer thickness

- ELPEGUARD SL 1301 ECO-BA-FLZ/23: 102 g/(m²*d) at 60 µm layer thickness

The parameter that describes this insulation behavior is the so-called moisture/insulation resistance, the Moisture and Insulation Resistance (MIR) - often used synonymously with SIR = Surface Insulation Resistance. In the following, the electrical insulation resistance under moisture is examined in more detail.

The moisture/insulation resistance used in various qualifications is a combined property of material and electrode system. It represents a complex resistance system between two metal electrodes in a comb layout consisting of various dielectrics such as laminate, coating, air and air humidity as well as possible leakage currents from ionic contamination - i.e. the movement of charge carriers in this electrode system.

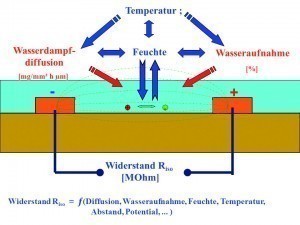

Fig. 2: The dependence of the moisture and insulation resistance of a coating on temperature and humidity in a cyclic humidity-temperature test [Tomlin NPL-Report CMMT(A) 2000].

Fig. 2: The dependence of the moisture and insulation resistance of a coating on temperature and humidity in a cyclic humidity-temperature test [Tomlin NPL-Report CMMT(A) 2000].

It describes the direct electrical effects of moisture absorption in this electrode system, which are comparable to those on an electronic circuit carrier. An insulation drop induced by moisture absorption is described as the remaining insulation value. The so-called surface resistance generally characterizes the functionality of electronic assemblies. Its drop to values below 1 MOhm is generally regarded as critical. With a coating, the previously given surface resistance (SIR - surface insulation resistance) between the potentials is replaced by the electrical resistance of the coating film. This is often the reason for the incorrect description of the electrical resistance of the coating as an SIR value. In various regulations, for example, the accepted insulation drop under moisture (temperature) load is limited to 100 MOhm.

Typical test structures for determining the moisture/insulation resistance are the comb layouts, such as those found on various IPC test boards. The IPC-B24 and IPC-B25A test boards are primarily used for the characterization of protective coatings.

This type of test is used to quickly detect moisture-induced defects. Similar to the so-called 'Highly Accelerated Stress Test' (HAST), different temperature levels and/or different relative humidities are used for this purpose.

Typical temperature/humidity combinations are, for example, 65 °C/90 % RH and 85 °C/85 % RH. The applied humidity occupies the surface of the measuring arrangement or is absorbed by the polymers, and an electrolytic cell is generated with the applied bias voltage (bias, usually between 5 and 100 V direct current). Typical failure mechanisms are then electrochemical corrosion processes and/or delamination.

These tests can be carried out

- as part of a product qualification (solder resist, protective coating, no-clean flux, etc.)

- as part of a process qualification (protective coating, soldering processes, cleaning processes, etc.)

- to compare different materials

- to compare different processes.

In this context, the moisture and insulation resistance can be regarded as a composite parameter - as a qualifying feature that describes the results of various physical parameters reduced to one characterizing feature.

Typical dependencies of the moisture/temperature behavior of coating materials and their description via the moisture/insulation resistance are shown in Tomlin's measurement curves (Fig. 2a and b).

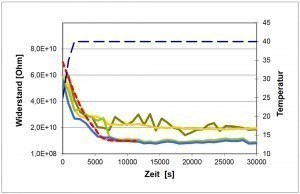

These diagrams also show the typical transient response of the resistance value, for example during drying (curve 2 b). These transient curves are typical diffusion-related dependencies. A typical transient for moisture absorption can be seen in the detailed section of a measurement curve (Fig. 3). Fig. 3: Transient of the moisture/insulation resistance with the onset of moisture exposure (40 °C / 100 % r. h.)

Fig. 3: Transient of the moisture/insulation resistance with the onset of moisture exposure (40 °C / 100 % r. h.)

This shows the transient response of the moisture/insulation resistance of a coating film during a condensation water test at 40 °C / 100 % RH / 100 V in the initial transient phase. Various protective coating films (colored lines) are included in the graph. Also shown is the error function (dotted line = erf(x)), which describes the typical mathematical solution of the one-dimensional diffusion equation. This means that the transient process can be described mathematically by a diffusion process, or diffusion processes, such as those on which water vapor permeability is based, can be detected via the drop in moisture/insulation resistance. The otherwise detectable diffusion values - expressed in g/cm² µm d - are translated here as electrical resistance values; the same applies to water absorption: values that are otherwise described as percentages can be obtained directly by translating the moisture/insulation resistance into electrical resistance values.

The following Table 1 lists various tests of six different ELPEGUARD protective coatings, from which, however, no correlation can be recognized on the basis of the values given.

|

DSL 1600 E-FLZ/75 |

SL1307 FLZ/232 |

SL 9407 FLZ |

UTC 1507 FLZ |

SL 1301 |

SL 1800 FLZ |

|

|

Harmful gas test |

GX |

GX |

GX |

GX |

GX |

GX |

|

Water vapor permeability |

240 |

37 |

32 |

25 |

102 |

37 |

|

SIR, 1000 h, 85 °C/85 % rel. h. |

7,9 |

9,4 |

8,1 |

10,1 |

8,2 |

9,6 |

|

Iodine vapor test |

none |

none |

large |

small |

small |

none |

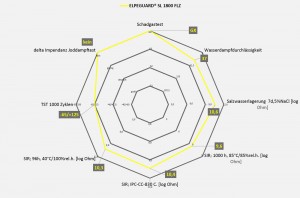

The following diagram (Fig. 4) shows various test results for the acrylate protective coating ELPEGUARD SL 1800 FLZ in order to recognize a possible correlation in a direct comparison.

This approach clearly shows that water absorption and water vapor permeability, among other key figures, are important parameters when considering the protective effect. However, each individual measured value alone is not meaningful enough to allow a generally valid conclusion to be drawn about the quality of a protective coating against environmental stresses and, above all, moisture stresses.

Measurements of moisture and insulation resistance (so-called SIR or MSIR values Moisture Surface Insulation Resistance) can be directly measured and utilized as electrical resistance.

If these electrical resistance values are determined in sequential test series (measurement of SIR values under condensation K08, alternating temperature test K05, damaged gas test K18, etc.) as part of validation tests, the sum of these values is the best way to assess the quality of the protective coating applied. It is important that this not only allows a statement to be made about the material used on assembled validation boards, but also about the entire conformal coating process and the upstream soldering process of the electronics.