Some stories begin in an extraordinary way and continue in an extraordinary way. It is an example of initiative, commitment and courage, in other words entrepreneurship. In this case, it is the story of the Swiss PCB manufacturer Varioprint, which, perhaps in keeping with the motto "in every crisis lies an opportunity", has successfully survived for a proud 50 years in a highly competitive industry.

50 years of Varioprint and a special change of ownership

On February 16, 1970, Varioprint AG was founded by Juan Jans and a few others as a printed circuit board manufacturer in Heiden in the Swiss Appenzell region  Fig 1: How it all began, Varioprint AG in the 70s (Fig. 1). At the beginning of the 1990s, when the economic situation was difficult, Varioprint and its 80 employees found themselves in financial difficulties.

Fig 1: How it all began, Varioprint AG in the 70s (Fig. 1). At the beginning of the 1990s, when the economic situation was difficult, Varioprint and its 80 employees found themselves in financial difficulties.

The then Managing Director Andreas Schmidheini from Tyco Electronics and four other executives who had joined the company decided on a management buy-out (MBO) in 1993 in order to save the company, its employees and their own jobs.

"We believe in the future of this company because we are at the forefront of technology. But it also takes an incredible amount of courage to tackle this project," said Andreas Schmidheini, summarizing the mood at the time.

1993 versus 2020, a success story

Whereas in 1993, the first management buy-out (MBO) of Varioprint AG, only 5% of global PCB production was produced in Asia, today it is 90%.

In contrast, the share of Fig. 2: Varioprint AG today in Heiden/Appenzellerland above Lake Constancein Europe and the USA has shrunk to 10%.

Fig. 2: Varioprint AG today in Heiden/Appenzellerland above Lake Constancein Europe and the USA has shrunk to 10%.

Thirty years ago there were over 1000 PCB manufacturers in Europe; this year there are barely more than 180 companies left, today including the Eastern bloc.

In 1993, Varioprint generated sales of around 12 million Swiss francs with 83 employees. In the coronavirus year 2020, the target was CHF 33 million with a workforce of 145 employees.

At that time, conductor track widths of 200 µm (width of 3 human hairs) were the challenge; today, 35 µm (1/2 human hair) is state of the art in order to be competitive.

Prices in 1993 versus 2020 are also worlds apart. Back then, a printed circuit board for an electricity meter from Landis & Gyr cost a hefty CHF 19, whereas today it is available from Asia for CHF 2.10.

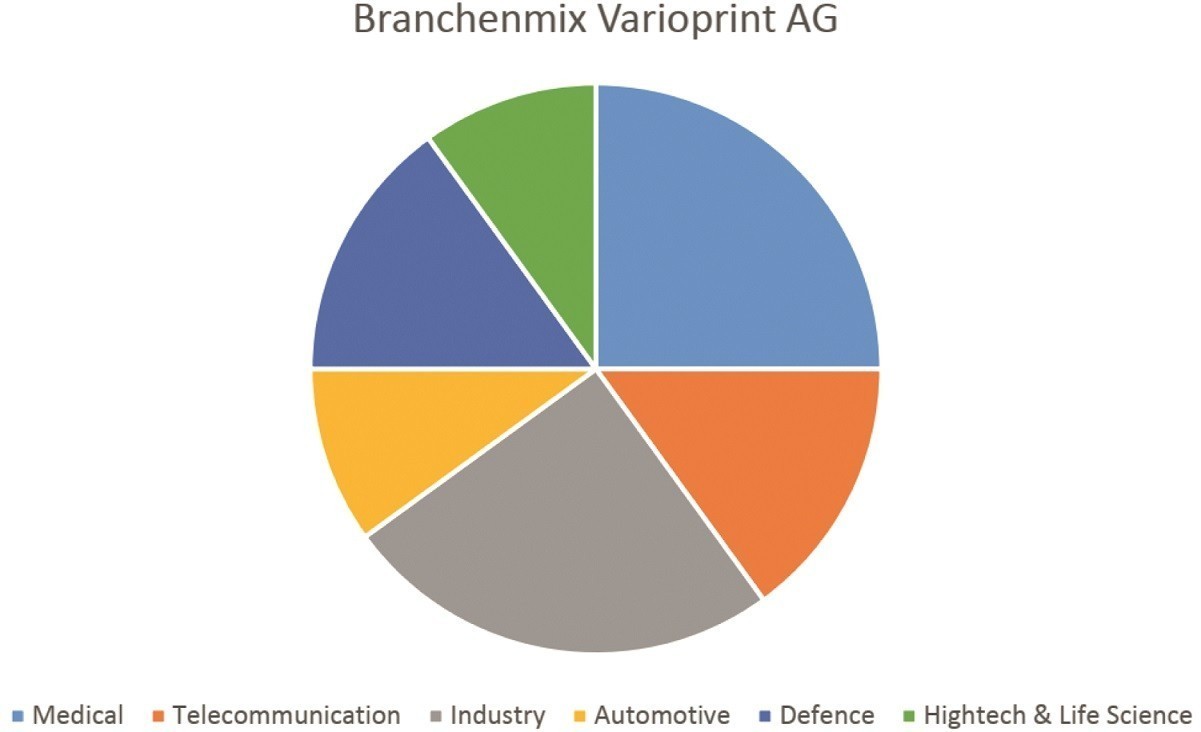

Fig. 3: Varioprint AG sector mix

Fig. 3: Varioprint AG sector mix

Varioprint AG industry mix: around 25% of printed circuit boards are used in medical and industrial applications, around 15% in telecommunications and military technology and around 10% in the high-tech & life science and automotive segments (Fig. 3).

High investment rate secures the future

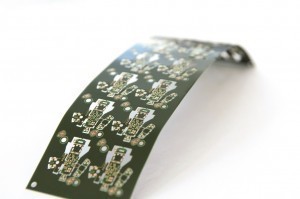

Fig. 5: Flex printed circuit board, minimum material thickness 12.5 µm and minimum conductor track width 35 µmAforward-looking and long-term oriented innovation policy covers the requirements of tomorrow. On average, 10% of turnover is invested in new systems/technologies every year, thus documenting the high level of innovation.

Fig. 5: Flex printed circuit board, minimum material thickness 12.5 µm and minimum conductor track width 35 µmAforward-looking and long-term oriented innovation policy covers the requirements of tomorrow. On average, 10% of turnover is invested in new systems/technologies every year, thus documenting the high level of innovation.

With the strategy of concentrating on high value-added products, there has been a rapid change from the simple printed circuit board with a track width of 150 µm to highly complex structures with 35 µm tracks (Fig. 4/5). Recently, Varioprint AG became the first company in the world to integrate optical waveguides into the PCB - a technology that increases transmission speed by a factor and is used in both telecommunications and sensor technology.

Questions for the former owner

PLUS: What trends do you see as market drivers today?

Andreas Schmidheini: The trend towards miniaturization and higher packing density is continuing. This is associated with high demands on ultra-fine conductor technology (conductor width/trace spacing, hole diameter), to which we have responded quickly by investing in the latest systems. In terms of materials, thinner materials with high stability are required.

Which technologies will be demanded by successful LP manufacturers in Europe in the future?

In addition to the above miniaturization trends, mastering frequencies in the mm- and µm-wave range will become a decisive success factor, requiring a high level of expertise in materials and the metallization of thin layers. The chip and PCB industries are increasingly converging and the technology of integrated optical waveguides will play an important role in this.

How has the coronavirus crisis changed your company?

The coronavirus crisis has greatly expanded our internal networking to home offices and our ability to communicate with customers and suppliers via video. Our rapid crisis management and the protective measures we took allowed us to keep production running in shifts without interruption.

In which market segments are you mainly active and where do you expect further growth potential for your company?

We are traditionally very broadly diversified and our technology portfolio enables further growth, particularly in the medical and telecommunications markets. Examples include complex high-frequency circuits, oversize PCBs, rigid-flex boards and hybrid assemblies or optical PCBs. We differentiate ourselves through new technologies and our expert advice and support for demanding projects.

Varioprint is based in Switzerland, a high-wage country. How important are exports for your company?

Varioprint operates globally and sees itself as a specialist for complex requirements. Exports now account for 75% of our business and are a mainstay of our company. For large projects in the automotive sector, we work successfully with Dynamic from Taiwan.

Have you started networking work processes in the direction of Industry 4.0?

For years, we have been making sure that our systems have interfaces so that we can monitor and control processes using the collected data. Industry 4.0 is very important to us and this will continue to increase.

Do you still have enough suppliers in Europe?

If you look at the question of risks, the supplier base is the most important one. Unfortunately, this is continuing to crumble and is increasingly shifting to Asia. At the moment, we still have sufficient supplies from Europe. The long-standing and close partnerships with our suppliers help us a lot to minimize the risks of supply security, especially in the current phase of Covid-19.

What makes Varioprint successful? Why do customers come to you?

In addition to our technological capabilities, based on many years of experience and state-of-the-art equipment, it is our values: trust - responsibility - reliability and fast and short decision-making processes that inspire our customers. As an owner-managed company, we understand our customers' needs and want to exceed them with a committed workforce.

You and your colleagues have been going down the hard road of an MBO since 1993. What motivates you and the existing shareholders to open up this path to a new generation of managers?

My colleagues and I are reaching retirement age after thirty or more years with the company. It's time to let go. We are handing over our life's work to the next generation in order to secure the company, the location, the culture, the spirit and the commitment to our business partners in the long term and to guarantee technological development. The company will remain owner-managed - the decisive success factor for the future!

What qualities were important to you in the new owners that a financial investor or competitor might not have brought as a buyer?

My successor Nicolas Härtsch (above) and his team know the complexity of the industry, the products and our processes through their work and are therefore in a position to further develop the company conceptually and strategically. Social skills, leadership experience, entrepreneurial spirit and passion are essential qualities. With a financial investor as a potential buyer, internal acceptance would not have been given. We did not want to take the risk of a cultural change and the expected staff turnover. With the chosen concept, the existing "feu sacré" can continue to be used successfully. The sacred fire, the enthusiasm, the burning for a task).

Will you still be with Varioprint in the future?

At the end of June 2020, I will be moving from my position as CEO to the role of Chairman of the Board of Directors (similar to Chairman of the Supervisory Board) and will therefore continue to support the company strategically with all my energy over the next few years.

In a nutshell:

- In 1993, 5% of the world's printed circuit boards were produced in Asia, today it is 90%. The USA and Europe together have a global market share of 10%

- At the time of the MBO in 1993, Varioprint AG achieved a turnover of CHF 12 million with zero export sales; this year, the aim is to achieve a turnover of CHF 33 million with an export share of 80%.

- Technologically, Varioprint is active in many high-tech segments. These range from HDI multilayer to high-frequency PCBs, rigid-flex PCBs and flexible PCBs to metal core PCBs etc.

- The company has received many prestigious awards for its achievements, such as the Entrepreneur Award for Eastern Switzerland, the Swiss Technology Award and the Entrepreneur of the Year Award from Ernst & Young

During the interview, the author asked outgoing partner and CEO Andreas Schmidheini: If he had one wish for the European LP industry, what would it be? His answer: Despite structural changes, cooperation between the remaining European manufacturers should be further intensified. Strengthening our industry in Europe also requires a commitment from suppliers to maintain their development base in Europe and for the market to take a total-cost-of-ownership approach across the entire value chain.

We can only add one more wish: May Varioprint AG, with its new CEO Nicolas Härtsch and the dedicated employees who carry this company in particular, continue to sail a successful course in the rough seas of the PCB industry.

With best regards to the Appenzell region

Yours

Hans-Joachim Friedrichkeit

Contact

www.pcb-network.com