In a recent white paper, Unimicron Germany presents the advantages and possible applications of an FR4-based planar coil compared to a conventional component.

If you look at today's innovative electronic systems, you realize that they are becoming more and more powerful on the one hand and more and more compact on the other. The housing and components are getting smaller, while performance is increasing. There is no longer enough space on the PCB to guarantee the required functionality.

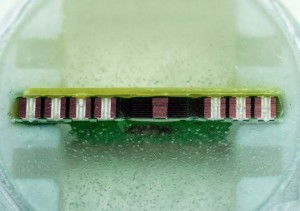

Fig. 2: WPC coil for transmitting power and dataThisbalancing act presents many a developer with major challenges. Embedding can be a potential solution. This involves integrating passive or active components into the PCB. The concept described in the white paper makes it possible to transform a passive PCB into an active component based on a defined multilayer.

Fig. 2: WPC coil for transmitting power and dataThisbalancing act presents many a developer with major challenges. Embedding can be a potential solution. This involves integrating passive or active components into the PCB. The concept described in the white paper makes it possible to transform a passive PCB into an active component based on a defined multilayer.

When wire-wound coils reach their limits

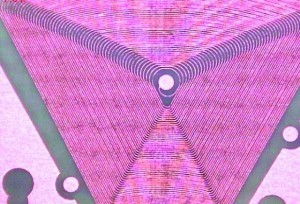

Based on the interaction of electric fields, many sensors and actuators are realized with conventional, wire-wound inductors. If an electronic assembly is subject to higher requirements, e.g. in the area of ambient temperature and temperature fluctuations, conventional components often have a limiting effect in terms of insulation classes and expansion coefficient. The alternative use of embedded planar coils in FR4, on the other hand, opens up unimagined perspectives. Thanks to advanced ultra-fine conductor technology, new base materials and optimized calculation and simulation tools, both the smallest planar inductors and high-current-resistant coil applications for wireless power charging (WPC), for example, can be realized.

When FR4, copper conductor track and core become one component

Customized coils are manufactured in a state-of-the-art production facility geared towards ultra-fine conductor technology. All required parameters are incorporated into the digital calculation and data preparation of the coil. In production with a high degree of automation and class 10,000 clean rooms, the conductor tracks are precisely registered and contacted in the inner layers. Thanks to the exact positioning and digitalized production, optimum coil values, the smallest tolerances and extremely high reproducibility can be achieved. With the innovative FR4-based coil technology, windings with a higher copper fill level and precise symmetries can be produced. FR4 planar coils are characterized in particular by their high current carrying capacity, low parasitic capacitance and minimized ohmic resistance. They also have better values in terms of insulation class and expansion coefficient, which increases the reliability of the assemblies. FR4 planar coils offer greater flexibility in terms of size and possible contacting variants (pads, half-holes or pins).

The high integration density and high copper fill level of FR4 planar coils also have a positive effect on signal integrity and thermal management.

When the advantages outweigh the disadvantages

The use of FR4-based planar coils offers the following advantages over conventional inductors:

Manufacture:

- Small size and flat height

- High copper fill level in the same space

- High current carrying capacity

- High vibration and oscillation resistance

- fewer skin effects due to flat conductor paths

- less leakage inductance due to short paths

- high precision of the layers and exact producibility

- Reproducibility in any quantity

- Combination with other PCB technologies

Assembly:

- Low center of gravity of the assembly

- No transition points with metals other than copper due to embedding in multilayer

- Use of standardized assembly and mounting processes

Reproducibility:

- Completely digital data preparation and production

- process-related narrower tolerance window across a production batch and follow-up orders

- Defined design rules and layer structures

Conclusion

If the current development of an electronic system, whether new or redesigned, involves the use of inductors and there are additional requirements in terms of miniaturization or heat dissipation, then the use of FR4-based coil technology can offer an optimal solution. FR4 planar coils can be embedded in a multilayer to save space, provide optimum values and are highly reliable. As individual components, they can be placed in trays and taped for easy processing in the standard assembly and mounting process. FR4 components are versatile and can be combined with additional PCB technologies such as HDI Microvia or Semiflex. If this is required, coordination during the development phase is recommended.

Application examples

FR4 coil technology is versatile and can be used in a wide variety of applications. Some practical applications can be found in the white paper, which can be downloaded from the following link.

https://unimicron.de/white-paper-download-planarspulen-auf-fr4-basis.html

Unimicron Germany (formerly Ruwel) is a traditional manufacturer of printed circuit boards in Germany. The highly automated inner layer plant is one of the most modern in Europe. The broad product spectrum ranges from printed circuit boards in standard technology such as double-sided PCBs and multilayers up to 30 layers to more sophisticated technologies such as HDI, thick copper technologies, high-frequency PCBs or semiflex. Unimicron manufactures samples, small and medium batch sizes or large quantities. As a High Reliability Business Unit within the Unimicron Technology Group, a global manufacturer of PCBs, Unimicron Germany has direct access to the Asian partner plants.