If we humans want to communicate across cultures and continents, we need communication structures and a standardized language. This is the approach taken by the international language Esperanto, which was first published in 1887. In the modern industrial environment of the 21st century, the task is very similar.

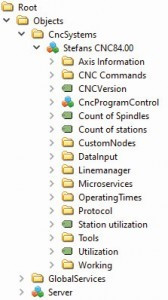

The OPC UA data model can be represented as a tree structure SIEB & MEYER, a supplier of CNC controllers for PCB processing (drilling and milling), has been familiar with connecting its own products to third-party systems for many years. These include DNC servers for the provision of process parameters such as machine-specific part programs, tool data and production parameters as well as the connection to MES and ERP systems. As in many other areas, these interfaces have grown and developed over a long period of time. They are used to meet industry-specific requirements and can therefore be described as proprietary. A universal industry standard did not exist until now.

The OPC UA data model can be represented as a tree structure SIEB & MEYER, a supplier of CNC controllers for PCB processing (drilling and milling), has been familiar with connecting its own products to third-party systems for many years. These include DNC servers for the provision of process parameters such as machine-specific part programs, tool data and production parameters as well as the connection to MES and ERP systems. As in many other areas, these interfaces have grown and developed over a long period of time. They are used to meet industry-specific requirements and can therefore be described as proprietary. A universal industry standard did not exist until now.

In recent years, the need for efficient optimization and flexibilization of production processes has also increased rapidly in the area of PCB production. The requirements include

- efficient production planning

- Measurement data acquisition / analysis

- process automation

- 'quantity 1' production: self-describing product

- Predictive maintenance

In general, these points are also summarized under the term 'Industry 4.0'. The prerequisite for achieving this goal is consistent networking of the components involved. Standardized communication interfaces are just as important, from the company level (ERP) to the field level to which the CNC control is assigned. For this reason, the company has equipped its CNC controls with a standardized interface in order to be open to future requirements.

Smooth exchange of machine data

Market analyses have shown that OPC UA is becoming increasingly established as the standard for M2M communication in a wide range of areas. The Lüneburg-based company has focused on this. In addition to the standardized and future-oriented data interface, the focus is on an extremely robust and stable solution that works reliably in 24/7 operation.

The service-based OPC UA communication protocol (OPC Unified Architecture) is the successor to the classic OPC standard. The OPC UA standard enables machine data to be described and exchanged regardless of manufacturer and platform. This means that data can be made available between all connected systems in a company.

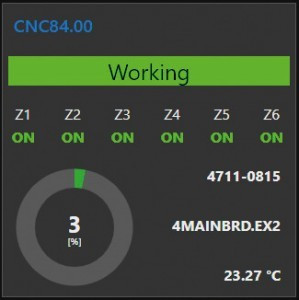

Thanks to the status display, the user can keep an eye on the CNC statusDatais forwarded between the client and server at runtimeviathe OPC UA interface. The OPC UA server displays variable names with the variable type as well as many different objects with any information and their relationships to each other. Functions such as historical data or alarms are defined on the basis of names, values, attributes, methods and events. For example, an object is a control mechanism for the wear of a drill with a drill stroke counter, alarm parameters and alarm limits.

Thanks to the status display, the user can keep an eye on the CNC statusDatais forwarded between the client and server at runtimeviathe OPC UA interface. The OPC UA server displays variable names with the variable type as well as many different objects with any information and their relationships to each other. Functions such as historical data or alarms are defined on the basis of names, values, attributes, methods and events. For example, an object is a control mechanism for the wear of a drill with a drill stroke counter, alarm parameters and alarm limits.

The OPC UA standard is defined by the OPC Foundation (IEC 62541) and is implemented by SIEB & MEYER:

- Basic data types, unit systems and transmission protocols

- Access to data (DA)

- Historical data (HA)

- Alarms and notifications

notifications (AC)

OPC UA is device-independent. Various standard tools for handling data from an OPC UA server are available on the market. These can be connected directly to the OPC UA servers of the controllers. Knowledge of the OPC UA standard is sufficient to enable data communication with the CNC controllers. Automation is easy to implement using OPC UA standard libraries in various programming languages (e.g. C#, Python, Node.js). Specific know-how of proprietary interfaces is no longer required: the user can concentrate entirely on the data and its processing.

The idea behind OPC UA is to map each device in its own data model. This describes itself and is published via an OPC UA server. This is exactly what SIEB & MEYER does: each CNC controller provides its own data model. This can be enriched with data that is provided by additional sensors on a machine. This is done using the OPC UA Integrator supplied. The OEM therefore also has the option here of integrating its machines into standardized infrastructures and still setting itself apart from the competition, e.g. through features such as the option of continuous status analysis using vibration.

analysis using vibration and temperature data. Freely usable data end points also allow the integration of customer and production-specific data such as order number, batch number, etc. Furthermore, functions offer the option of loading necessary process parameters such as the part program and tool parameters into the CNC. This makes it possible to implement an automated data supply that creates a high level of process reliability.

Also suitable for retrofitting

SIEB & MEYER also offers a server-oriented interface solution: The 'SM IIoT Platform' is connected to various CNC controllers (machines) and displays their data with all features. This variant is also suitable for retrofitting older (CNC 8x.00-controlled) machines.

Standardized communication interfaces are the prerequisite for consistent networking of the components involved in the sense of Industry 4.0 (Pictures: Sieb & Meyer AG)

Technical properties:

- Basis: Self-describing data model organized as a tree structure

- Modern microservice

architecture - Data content based on

JSON format - Internal broker architecture decouples data source (CNC) from data sink (OPC UA server)

- Service Manager core component: manages data model and services, such as

9x Connector (CNC 93.00, CNC 95.00), 8x Connector (CNC 82.00, CNC 84.00,

CNC 82AS), OPC UA server, other services (Sensorics, OPC HA), internal services

OPC UA is the future standard data interface for SIEB & MEYER, which is available on current CNC 95.00 and CNC 93.00 systems if required. The interface can also be added for the predecessor systems CNC 8x.00 since February 2021 (software version 21.02.003), so that existing systems can also be fully connected. This allows the CNC control systems to be easily integrated into future-oriented infrastructures. This ensures that customers can react flexibly to the growing requirements of modern production environments.