PCB manufacturer KSG offers a series of webinars on all aspects of PCBs. A new series '3D printed circuit boards' was launched in October 2020. Part 1 compared three technologies for the production of 3D printed circuit boards. Part 2 will follow on January 28, 2021.

Semi-flexible printed circuit boardInpart 1 of the KSG webinar, rigid-flex printed circuit boards of different designs, semi-flex printed circuit boards and HSMtec 3D printed circuit boards were discussed and compared in detail.

Semi-flexible printed circuit boardInpart 1 of the KSG webinar, rigid-flex printed circuit boards of different designs, semi-flex printed circuit boards and HSMtec 3D printed circuit boards were discussed and compared in detail.

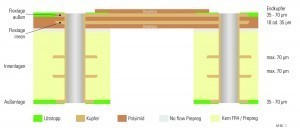

1. rigid-flex PCBs: Rigid-flex PCBs are a combination of conductor track structures on flexible polyimide films and rigid FR4 material. These are offered in different structures:

- With one asymmetrical flex layer

- With two asymmetrical flex layers

- With two flex layers symmetrical

Due to the high flexibility of the polyimide films, rigid-flex PCBs can be used to achieve tight bending radii of ≥ 1 mm (with one flex layer) and ≥ 3 mm (with two flex layers), even in complex installation situations. Multiple bends are possible. The conductor track widths and spacings can be as small as 150 µm. Impedance-controlled circuits can be produced. The complex production process makes this type correspondingly expensive.

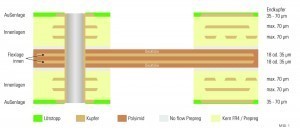

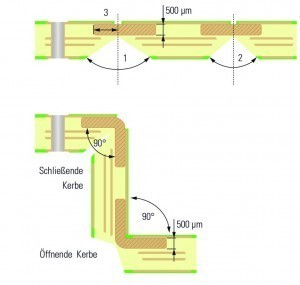

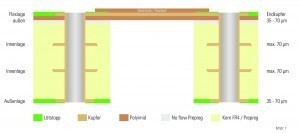

2 Semi-flexible printed circuit boards: In contrast to rigid-flex PCBs, the flex area of the semi-flex variant is not made of polyimide, but instead a thin FR4 prepreg layer is used. Various structures are also available here. The more cost-effective variant compared to rigid-flex PCBs is only suitable for fixed mounting. The bending radii are usually ≥ 5 mm. Semi-flexible PCBs can also be produced with a line/space ≥ 150 µm.

3. HSMtec 3D printed circuit boards: With this technology, copper profiles are incorporated into the outer area of a multilayer PCB, which can then be bent after the excess base material has been milled out. The copper profiles also act as heat sinks. An HSMtec 3D PCB is self-supporting and is particularly suitable for use in the high current range up to 400 A and for thermal management when LEDs are installed. Multiple bending is not possible.

The PCB manufacturer, which produces at its sites in Gornsdorf in Saxony and Gars in Lower Austria, plans to offer the second part of the webinar on 3D printed circuit boards on January 28, 2021. The topic is: 'Constructing, designing and optimally using multidimensional PCBs'. Interested parties can register online at the following address.