In 1953/54, Karl Ziegler and his colleagues at the Max Planck Institute for Coal Research in Mülheim an der Ruhr developed a significantly improved process for the production of polyethylene thanks to the then sensational discovery of catalysts that enabled the linking of individual ethylene molecules under very simple conditions and with unprecedented efficiency. This discovery made it possible to provide a whole class of Ziegler catalysts to convert the next higher homologs of ethylene, such as propene, butene, etc., into previously unknown solid, plastic-like and semi-crystalline products. But that was not all. The catalysts proved to be the key to the large-scale worldwide production of the new, diverse plastics for whose discovery Karl Ziegler was awarded the Nobel Prize in 1963 [1].

Fig. 1: Adolf Butenandt's visit to the Max Planck Institute in Mühlheim/Ruhr (from left to right: Butenandt, Ziegler and Lehmkuhl)When Herbert Lehmkuhl came to the Mühlheim Institute in January 1953 to do his diploma thesis and, "if he proves himself", his dissertation, he was asked the following question by Karl Ziegler: "You know that aluminum cannot be separated from aqueous solutions. Dr. Köster recently made complex compounds between an alkali metal fluoride and aluminum triethyl, whereby the alkali metal can be either sodium or potassium. Why don't you try to see if you can electrolytically precipitate aluminum from these complex compounds" [2]. As Herbert Lehmkuhl had also studied in Bonn under the renowned electrochemist Mark von Stackelberg, there was no reason for him to be "afraid" of electrochemistry or the preparative application of electrochemistry.

Fig. 1: Adolf Butenandt's visit to the Max Planck Institute in Mühlheim/Ruhr (from left to right: Butenandt, Ziegler and Lehmkuhl)When Herbert Lehmkuhl came to the Mühlheim Institute in January 1953 to do his diploma thesis and, "if he proves himself", his dissertation, he was asked the following question by Karl Ziegler: "You know that aluminum cannot be separated from aqueous solutions. Dr. Köster recently made complex compounds between an alkali metal fluoride and aluminum triethyl, whereby the alkali metal can be either sodium or potassium. Why don't you try to see if you can electrolytically precipitate aluminum from these complex compounds" [2]. As Herbert Lehmkuhl had also studied in Bonn under the renowned electrochemist Mark von Stackelberg, there was no reason for him to be "afraid" of electrochemistry or the preparative application of electrochemistry.

However, electrolysis with various complex electrolytes containing aluminum alkyl was very disappointing, as the conductivities of the melts of these compounds or even their solutions were very poor in the order of 10exp-4 S/cm. The aluminum precipitates were unsightly and also contained large amounts of alkali metal. The electrolytes used were complex compounds between alkali metal halides and aluminum triethyl, both monomers, the aluminum triethyl a Lewis acid, the halide anion a Lewis base, so that a complex was formed.

Due to the lack of success in electrolytically depositing pure aluminum and preventing the co-deposition of alkali metals, Lehmkuhl did something completely illogical. Out of desperation, he added more aluminum triethyl, even though the poorly conductive aluminum triethyl was not expected to improve the conductivity of the poorly conductive complex compound. However, Lehmkuhl knew that alkali metal could be reacted with aluminum triethyl to form aluminum. To his surprise, Lehmkuhl discovered that adding the non-conductor to a poor conductor produced a melt that conducted electricity at least two orders of magnitude better. Thus the new, so-called 1:2 complexes were born, in which two aluminum alkyls are coordinatively bound to an alkali fluoride:

M [R3Al-F] + AlR3 → M [R3Al-F-AlR3].

The deposited aluminum from this electrolyte looked shiny in the truest sense of the word and consisted of pure, silvery shiny aluminum. Even though the term was not yet known at the time, the 1:2 complex electrolytes were ionic liquids from which high-quality aluminum layers could be successfully deposited by electroplating for the first time. Karl Ziegler and Herbert Lehmkuhl were proud to present the successful electrodeposition of ultra-pure aluminum from aluminum-alkyl-containing complex compounds as a spin-off of catalyst development to the then President of the Max Planck Society, Prof. Adolf Butenandt, during his visit to the Mühlheim Institute (Fig. 1).

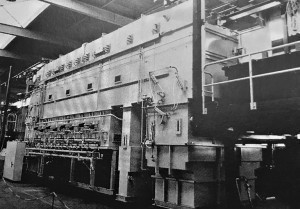

![Abb. 2: Kontinuierlich arbeitende Anlage zur galvanischen Aluminium-Beschichtung von Draht [3] Abb. 2: Kontinuierlich arbeitende Anlage zur galvanischen Aluminium-Beschichtung von Draht [3]](/images/stories/Redaktion_GT/thumbnails/thumb_GT5-20_gesch-2.jpg) Fig. 2: Continuously operating system for the electroplating of aluminum on wire [3]Since Lehmkuhl always knew how to test his scientific results for possible industrial application, he soon experimented with technical implementations, such as the continuous electroplating of aluminum on wire (Fig. 2).

Fig. 2: Continuously operating system for the electroplating of aluminum on wire [3]Since Lehmkuhl always knew how to test his scientific results for possible industrial application, he soon experimented with technical implementations, such as the continuous electroplating of aluminum on wire (Fig. 2).

The patent "Electrolyte and process for the electrolytic deposition of aluminum", filed in 1958, was granted and offered to companies in the electroplating industry for use, but "nobody was interested" [2]. Electroplaters were used to working with aqueous electrolytes, but here a flammable and air-sensitive electrolyte was required for aluminum deposition, which had to be operated in closed apparatus under inert gas. Lehmkuhl and his colleagues in Mühlheim therefore turned their attention to other topics.

Early on, analyses at Heraeus revealed that the electrolytic aluminum deposition process produced aluminum with a 5-nines quality, which was significantly purer than the aluminum anode quality used. As a result, electrolytic refining also took place in the 1:2 complex in addition to the galvanic aluminum deposition. This property of the complex aluminum electrolyte was used for more than 20 years by Vereinigte Aluminium Werke (VAW) in Bonn on an industrial scale for the production of ultra-pure aluminum, whereby the electrolytic aluminum separation was carried out in closed electrolysis cells with several hundred liters of the Mühlheim electrolyte system (Fig. 3). Approx. 1 t of high-purity aluminum was deposited annually from the aluminum-organic electrolytes in the VAW plants. Lehmkuhl [2] and Dötzer [4] worked intensively on the refining process of cathodic aluminum separation and anodic aluminum dissolution in the complex aluminum-alkyl-containing electrolytes. The fine purification of metals via their alkyl compounds, as demonstrated by Ziegler and Lehmkuhl, was applied by Dötzer [4] to the electrowinning of gallium and indium.

Around the beginning of the 1980s, the galvanic deposition of aluminum became interesting again, triggered in large part by the ban on the highly corrosion-resistant but very toxic cadmium, for which an alternative was sought. In the meantime, various working groups had also developed other aprotic electrolyte systems for electroplating aluminum, in which the aluminum was deposited from AlX3 (especially AlCl3, AlBr3, dissolved in aromatics) or AlH3 (especially LiAlH4 and AlCl3, dissolved in ethers, Philips process). However, none of these electrolyte systems reached the same technical maturity as aluminum deposition from the Ziegler-Lehmkuhl electrolyte [5].

Siemens had been working on aluminum deposition on a very small scale since the Mühlheim results became known around 1955, but now teamed up with a Dutch plant construction company, HGA B.V., to bring electroplated aluminum deposition to an industrial scale. In the following years, plating plants with a 2m3 electrolyte volume were put into operation at Hegin Galvano-Aluminium B.V. in Holland (ring cell plant) and at Sedec Galvano Aluminium KG, Decker GmbH & Co. KG in Berlin in 1983 with a 15m3 electrolyte volume (Fig. 4).

The commissioning of the plant in Berlin was an opportunity for Lehmkuhl and his colleague Klaus Mehler to resume work on electroplated aluminum deposition and to contribute to the further development of the electrolytes in the direction of higher current density load capacity and higher throwing power, whereby the service life of the expensive electrolytes could also be extended to > 5 years thanks to the fundamental electrochemical work and the development of a new analysis method [3].

With the availability of industrial galvanic aluminum coating systems, intensive contacts began with various industries, primarily the automotive industry. Here, the aluminum layers deposited from the alkyl-containing electrolytes proved to be extremely corrosion-resistant, especially at higher temperatures, due to their high purity. The high purity of the aluminium also allowed the layers to be anodized and dyed colourfast and chromated yellow and black (Fig. 5). Galvano-aluminum was included in the factory standards of several large automotive companies.

Following on from the further development of galvanic pure aluminum deposition from fluoride-containing, aluminum-organic electrolytes, Lehmkuhl, Mehler, Reinhold, Bongard and Tesche [6] succeeded in depositing aluminum and magnesium from toluene solutions of halogen-free, aluminum-organic complex electrolytes. The magnesium incorporation rates were selectable in a wide range by appropriate composition of the aluminum-magnesium alloy anodes or by separate anodic aluminum or magnesium circuits. The anodic and cathodic current yields were 100 %. The aluminum-magnesium layers are excellently suited as protection against contact corrosion on magnesium components. Electrochemical tests showed, for example, a pronounced passivity interval compared to the AZ91hp alloy at a magnesium installation rate of approx. 25 % by weight. Practice-oriented investigations in cyclic corrosion tests (simulated 10-year field load) showed no corrosion at all compared to galvanized and additionally silicate-sealed test screws.

Fig. 5: Excerpt: Various electroplated aluminum applicationsAlthoughelectroplated aluminum deposition from aluminum-organic electrolytes is currently operated industrially on a low flame, the wave-like interest in aluminum deposition from aluminum-alkyl-containing complex compounds has shown that the history of electroplated aluminum deposition is not necessarily over and that completely new opportunities may open up. But then at a significantly higher technical level and with considerably improved basic knowledge.

Fig. 5: Excerpt: Various electroplated aluminum applicationsAlthoughelectroplated aluminum deposition from aluminum-organic electrolytes is currently operated industrially on a low flame, the wave-like interest in aluminum deposition from aluminum-alkyl-containing complex compounds has shown that the history of electroplated aluminum deposition is not necessarily over and that completely new opportunities may open up. But then at a significantly higher technical level and with considerably improved basic knowledge.

Literature

[1] H. Martin: Polymers and patents - Karl Ziegler, the team, 1953-1998; Wiley-VCH, 2002

[2] H. Lehmkuhl: Vom Aluminium zum Nickel und wieder zurück - Eine Wanderung durch fast vier Jahrzehnte metallorganischer Chemie, transcript of the lecture held at the Max-Planck-Institut für Kohlenforschung on August 11, 1990

[3] H. Lehmkuhl; K. Mehler; U. Landau: The Principles and Techniques of Electrolytic Aluminum Deposition and Dissolution in Organoaluminum Electrolytes, Advances in Electrochemical Science and Engineering, Edited by Heinz Gerischer and Charles W. Tobias, VCH Weinheim, 3, 1994, 165-226

[4] R. Dötzer: High-purity metals by electroraffination in organometallic complex salt melts, Chem.-Ing. Techn. 36. Jahrg., 1964, 616-636

[5] S. Birkle: Technical progress in the electrodeposition of aluminum, Metalloberfläche 40, 1986, 6

[6] H. Lehmkuhl; K. Mehler; H. Bongard; B. Tesche; B. Reinhold: Electrolytic deposition of aluminum-magnesium alloys from organoaluminum complex electrolytes, Materials Science & Engineering Technology, Vol. 31, Issue 10, Oct. 2000, 889-898