In electroplating and other processes such as anodizing and waste water neutralization, bath agitation systems without air such as the SerDuctor nozzle system from Serfilco in Monschau are becoming increasingly popular. The advantages are higher layer uniformity and a lower risk of combustion.

Serfilco is one of the pioneers in bath agitation using nozzle systems. Founder and senior director Jack Berg has long been working on alternatives to bath agitation with air. His experiments with Venturi nozzles were successful. Eventually, the Serfilco SerDuctor nozzles with specific flow characteristics, which are still used today, were developed in-house. After initial hesitation, the bath movement without air initially became established in electroplating technology. "In the meantime, Serfilco nozzle systems are constantly conquering new areas of application, for example in waste water neutralization and anodizing processes. The QUALANOD organization for controlled, quality-assured anodized aluminium has also recognized the advantages of this process and gives a clear recommendation for its use," says Walter Masur, Head of Marketing and Sales at the Serfilco branch in Germany, which serves customers in the D-A-CH region. QUALANOD stands for Association for Quality Control in the Anodizing Industry.

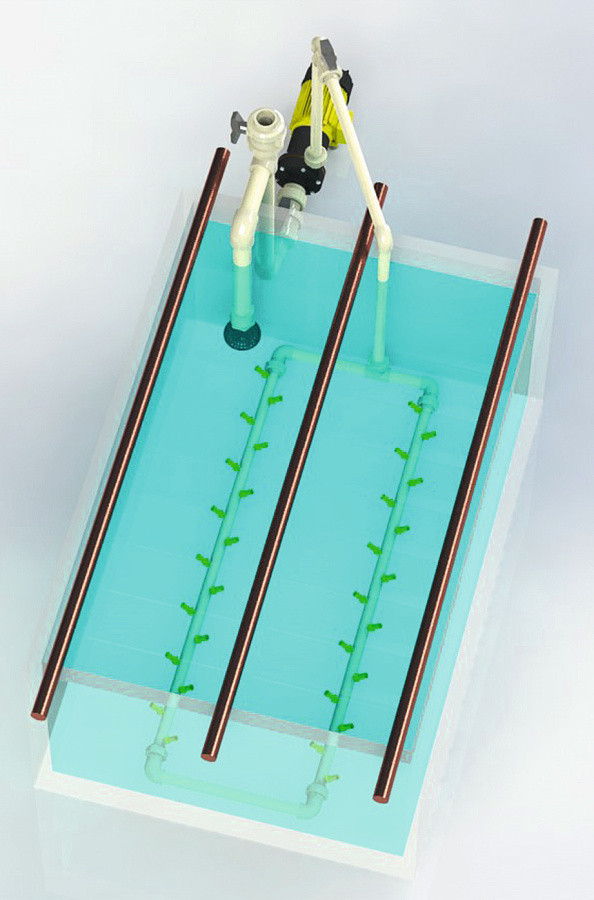

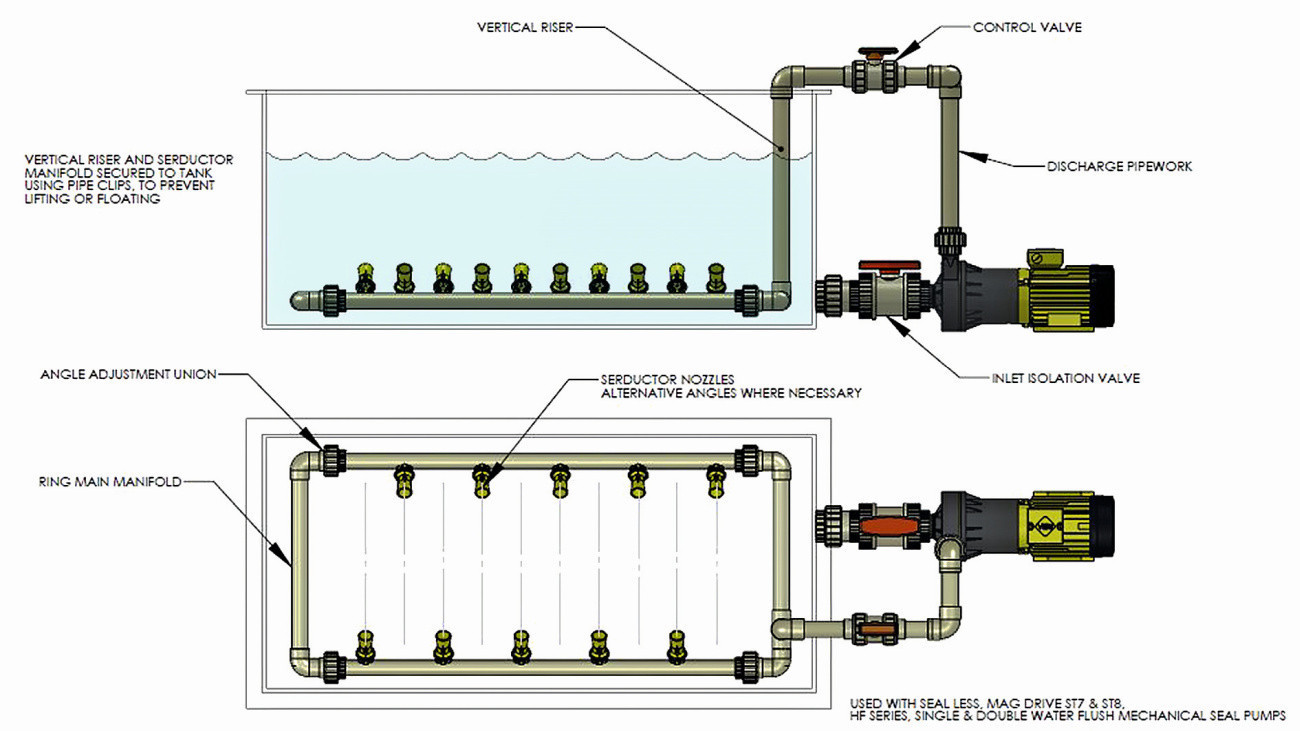

The system from the side and from above

The system from the side and from above

In a brief excerpt from the QUALANOD guidelines, the specifications for the QUALANOD quality label for the sulphuric acid-based anodizing of aluminium state: "The electrolyte movement relative to the workpieces should be sufficient to dissipate excess heat generated on the aluminium surfaces during the anodizing process.

Practical application of the SerDuctor nozzle systemMaintainingthe electrolyte temperature on the workpieces is a decisive factor because insufficient heat transfer can lead to poor anodic film quality, according to Serfilco. Sufficient movement can be achieved by both hydraulic turbulence and air movement. For batch processing, circulation of the electrolyte by conventional pump-over circulation is generally not sufficient to maintain proper temperature control in the bath, it adds. For effective batch processing, however, hydraulic turbulence could be generated using a pumped system with eductor nozzles at the bottom of the tank.

Practical application of the SerDuctor nozzle systemMaintainingthe electrolyte temperature on the workpieces is a decisive factor because insufficient heat transfer can lead to poor anodic film quality, according to Serfilco. Sufficient movement can be achieved by both hydraulic turbulence and air movement. For batch processing, circulation of the electrolyte by conventional pump-over circulation is generally not sufficient to maintain proper temperature control in the bath, it adds. For effective batch processing, however, hydraulic turbulence could be generated using a pumped system with eductor nozzles at the bottom of the tank.

Although the energy required for this is greater compared to low-pressure air movement, the difference is comparable to the loss of energy due to the evaporation of water from moving air. Hydraulic turbulence with Serfilco SerDuctor nozzle systems is said to provide greater agitation than air systems, improving layer uniformity and reducing the possibility of scorching. In addition, less acid mist is said to form on the surface of the baths.

The argument is supported by QUALANOD: Air bubbles increase the resistivity of the solution by up to 35% [1], which increases the electrical energy consumption for anodizing. The use of compressed air also leads to high evaporation heat losses, especially when used in conjunction with air extraction, they say. Furthermore, the use of high-pressure air is not a "best available technology" (BAT) due to its high energy consumption.

The SerDuctor nozzle system from Serfilco improves the quality and uniformity of coating thickness while reducing the possibility of burning/waste, Serfilco is convinced - and all this with lower energy costs and lower energy losses through evaporation.

Literature

[1] QUALANOD specifications, no. 34 dated 1.7.2022