The Neue Materialien Bayreuth GmbH research facility reinvented itself a few years ago and has been driving forward the development of material substitutions and energy- and raw material-efficient processes ever since. In addition to metal 3D printing, the Metals division also uses thermal spraying of metals and other materials - with impressive results!

Reducing dependencies

The European Union, the German government and the state governments have been pursuing the goal of reducing dependencies for some time and are therefore specifically promoting research and development into substitution solutions and new energy- and raw material-efficient processes.

This also benefits Neue Materialien Bayreuth GmbH (NMB), a non-university research institution whose basic funding is provided by the Bavarian state government. Bavaria is also the largest NMB shareholder with 55 percent, followed by the city of Bayreuth, the University of Bayreuth and the regional chambers of industry, commerce and crafts.

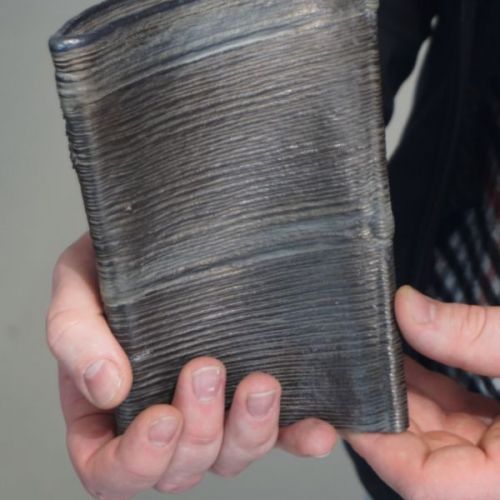

The industry-oriented research facility has now been in existence for 24 years. Industry-oriented products and processes are developed through cooperation with companies and research institutions. Under the leadership of Managing Director Prof. Holger Ruckdäschel, the focus since 2022 has been on digitalization, sustainability and new fields of technology and application areas. Metal 3D printing with wire: demonstrator made of titanium aluminide

Metal 3D printing with wire: demonstrator made of titanium aluminide

Practical research in future fields

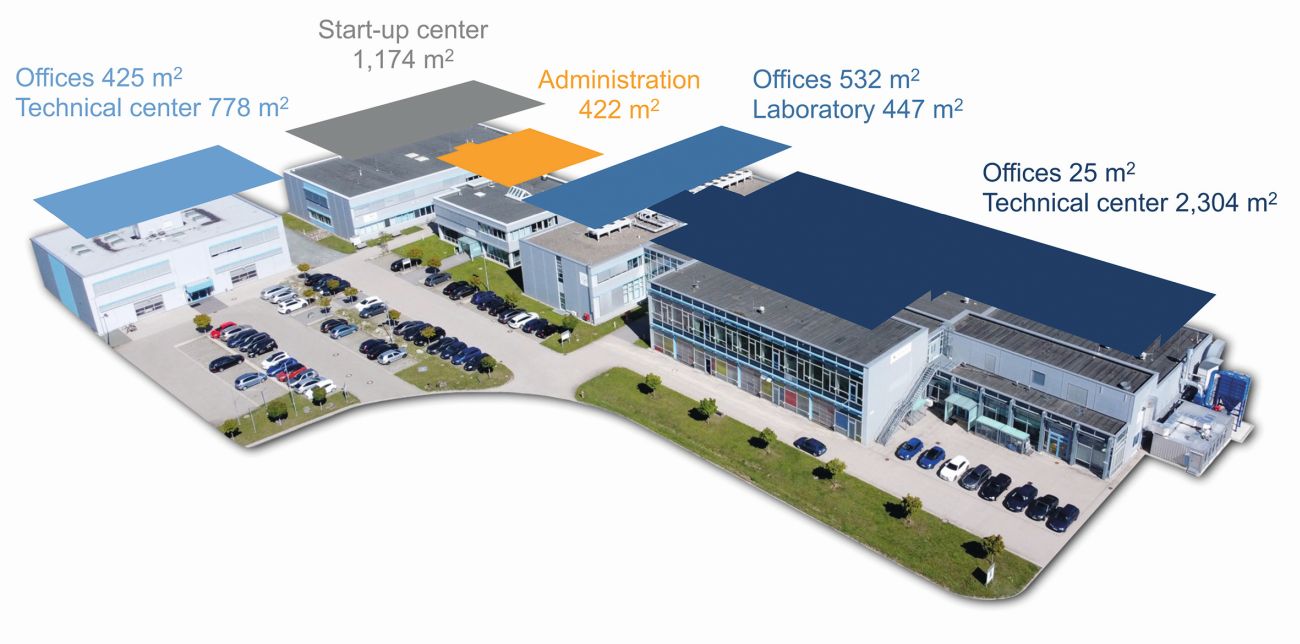

Many projects focus on energy and raw material efficiency, sustainability and material substitution. Since the turn of the millennium, many millions have been invested in buildings and technical equipment at the research facility on the outskirts of Bayreuth, a city of 75,000 inhabitants. Divided into the Metals, Plastics and Future Solutions divisions, around 100 scientists work in Bayreuth, including 55 permanent employees.

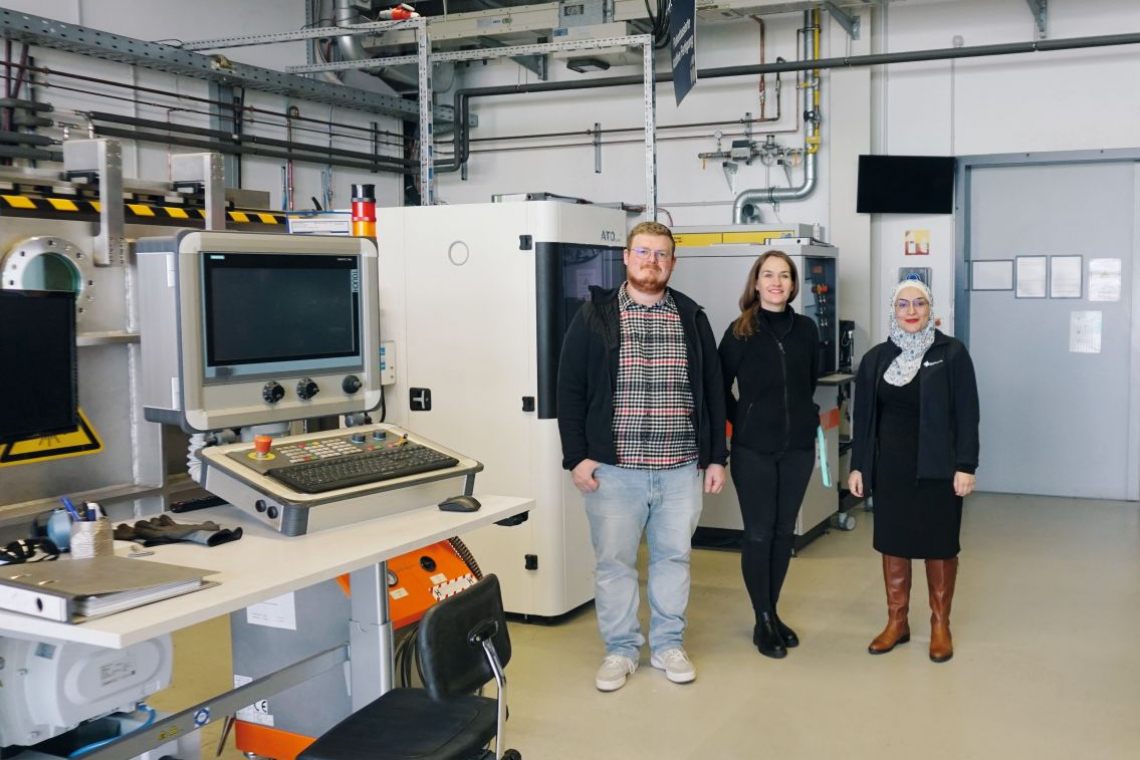

These include Agata Kulig, who specializes in powder bed-based additive processes, and Jonas Wölfel, an expert in wire-based additive manufacturing. Kulig has been here since 2019, originally studied materials science in Poland and joined the team in the wake of the hype surrounding the young 3D printing technology. Jonas joined after completing his Bachelor's and Master's degree in Nuremberg and is particularly enthusiastic about the practical orientation of the research facility with its high volume of industrial projects. Uwe Glatzel, who will be represented by his deputy Dr.-Ing. Haneen Daoud, who studied both chemistry and materials science with distinction and originally comes from Jordan, during the visit to "Galvanotechnik" in Bayreuth. This means that the best minds in research and development in Bayreuth have a multicultural face.

Meanwhile, the global battle for the forefront of technological research in the field of 3D printing is wide open: At the Formnext 3D printing trade fair, which was recently held once again in Frankfurt am Main, the team was able to see for themselves the progress made by non-European researchers in their field. "They have made a huge leap forward and have also become very good in terms of value for money. We had tears in our eyes when we realized how good they already are," Dr. Daoud describes her observations and adds: "For us, this is a challenge that we are happy to take on."

Surface technology with thermal spraying and 3D printing

Surface technology also plays a major role at the Bayreuth research facility. Particular attention is paid to the process of thermal spraying. A dedicated demonstration center for 3D printing and thermal spraying was set up for this purpose in 2021, which is located in separate containers next to the technical center building for reasons of process safety. A robot is located here that can apply surfaces using a combination of thermal spraying and 3D printing. For example, a process has been developed for improved sand molds in aluminum die casting. The robot injects polymer channels, which are then coated with aluminum. Thanks to this new method, die-casting tools can now be produced that cast components with significantly improved integrated cooling. Such parts are needed for heat dissipation in e-mobility, among other things. Another innovation is patient-specific endoscopes. Endoscopes are used to examine and manipulate the inside of the human body. By means of plastic printing and subsequent metallization of the printed hollow plastic structure, it is possible to customize the endoscope and significantly reduce the price - an important step towards affordable and efficient modern medicine.

Dr. Daoud in the demonstration center for thermal spraying

Dr. Daoud in the demonstration center for thermal spraying

Plastic, metal or composite coating

The robot itself is flexible and sprays particles at high speed onto components measuring up to two meters long and five meters wide using the so-called cold gas process. In addition to cold gas coating, components can also be coated using plasma and arc processes - processes that form very dense layers. The powders used for coating are not limited to metals; metal-ceramic composite layers are also possible, for example. The range of applications is therefore wide and can be varied in order to fulfill the respective application purpose.

For example, a battery tray for an electric car, which is located in the anteroom of the robot coating system next to 3D-printed geometrically complex parts, is used to improve electromagnetic shielding. Here, the robot has sprayed on a carbon layer to improve conductivity. After all, the high currents in electromobility have to take precisely defined paths in order to fulfill their purpose.

In-house powder production

The key medium for coating and additive manufacturing is powder, either from metals or other materials. Powder prices on the market currently vary greatly: while steel powder is already available for around 30 euros per kilogram, the price of special materials for this quantity can range from 500 to 1000 euros. The researchers in Bayreuth do not rely on purchasing, but also develop their own powders, which they produce themselves on site. Together with Agata Kulig and Jonas Wölfel, Dr. Daoud leads us into the technical centre, where a large silo-like cylinder rises more than three meters into the air on one wall. A long arm with a gun feeds commercially available wire to the so-called atomizer, where it is melted by an electric arc. It is then spheronized and collected in a container further down. The required fractions with particle sizes between 10-150 μm are then produced in a glazed apparatus next to the system by sieving under an argon atmosphere. New materials and processes at a glance: NMB scientists Kulig, Wölfel and Dr. Daoud

New materials and processes at a glance: NMB scientists Kulig, Wölfel and Dr. Daoud

New materials with wire-based 3D printing

Commercially available wire is also the material Jonas Wölfel works with. A new material has been created from different wires: Titanium aluminides, which are used in the aerospace industry. The material is produced by laser deposition welding by inserting two different wires. Jonas shows an example. It is a kind of vase with the typical grooves that are created when layers are built up in 3D printing. The material has a low density and a high melting point, is resistant to corrosion and oxidation and has a high specific strength. Interestingly, the energy input of the laser can be controlled and thus minimized as required. In addition, 100 percent of the input material is used, Wölfel points out the raw material efficiency of the process.

Iron-based wear protection - printed anodes

Speaking of new materials: the research facility has developed a new material for wear-resistant materials based on nickel, cobalt and tungsten, which consists of an iron matrix and reduced quantities of tungsten carbides. It is coated using laser powder cladding. The material itself offers high wear protection, high thermal conductivity and a hardness of more than 60 HRC (Rockwell hardness). This makes the new material as hard as a Damascus sword - the most resistant and hardest steel blade in existence.

The lead-free anodes for chrome plating are exciting, especially for electroplating shops. In a combination of 3D printing and thermal spraying, a stainless steel-coated plastic anode is created that encloses components and - suspended in the electroplating bath - can be chrome-plated in this way. Selective coating is also possible. The advantage: the plastic anode can be coated again and again, the use of heavy metals such as lead is eliminated and the process is said to be inexpensive.

A better world is possible

The processes presented here are just some of the research activities at the NMB. Numerous other processes are being developed in the technical center. Overall, a creative spirit prevails in the bright offices and workshops. The researchers approach their tasks with a great deal of ingenuity. One of the triggers for their motivation can be seen in the stairwell. A series of photos there shows employees in a green environment - with a globe in their hands, hidden between bushes and flowers or with their upper bodies exposed and programming commands painted on them. Ultimately, it's all about a better world - one that Neue Materialien Bayreuth is also working towards!

NMB in Bayreuth. The laboratory containers for thermal spraying can be seen on the far right - Illustration: NMB

NMB in Bayreuth. The laboratory containers for thermal spraying can be seen on the far right - Illustration: NMB