IMO Oberflächentechnik has been on the market for 50 years and during this time has grown from a small electroplating company to a 500-employee group of companies. With its two production areas of strip and single-part electroplating, the company is in the right place at the right time in the course of the electrification of the economy and counts global players such as Amphenol, Bosch, Continental, Siemens and ZF among its customers alongside medium-sized companies.

Salman Karatus checks one last time that the bronze strip is correctly positioned - then he starts production of the 80-meter-long strip line. The job will take 40 hours. During this time, countless filigree contacts for electronic automotive components will be electroplated, which can already be seen in the pre-punched strip. Other jobs take several days or even a week. At six to seven meters per minute, the bronze strip now unwinds from a spool, winds its way through several guide rollers and then enters various baths one after the other, starting with cleaning, various coatings of nickel, silver and tin and later passivation and drying. The 130 millimeter wide strip first runs 40 meters in one direction from bath to bath, is then diverted in the opposite direction, then runs through further baths and finally ends up as a silver-plated strip with a tin strip back on a spool.

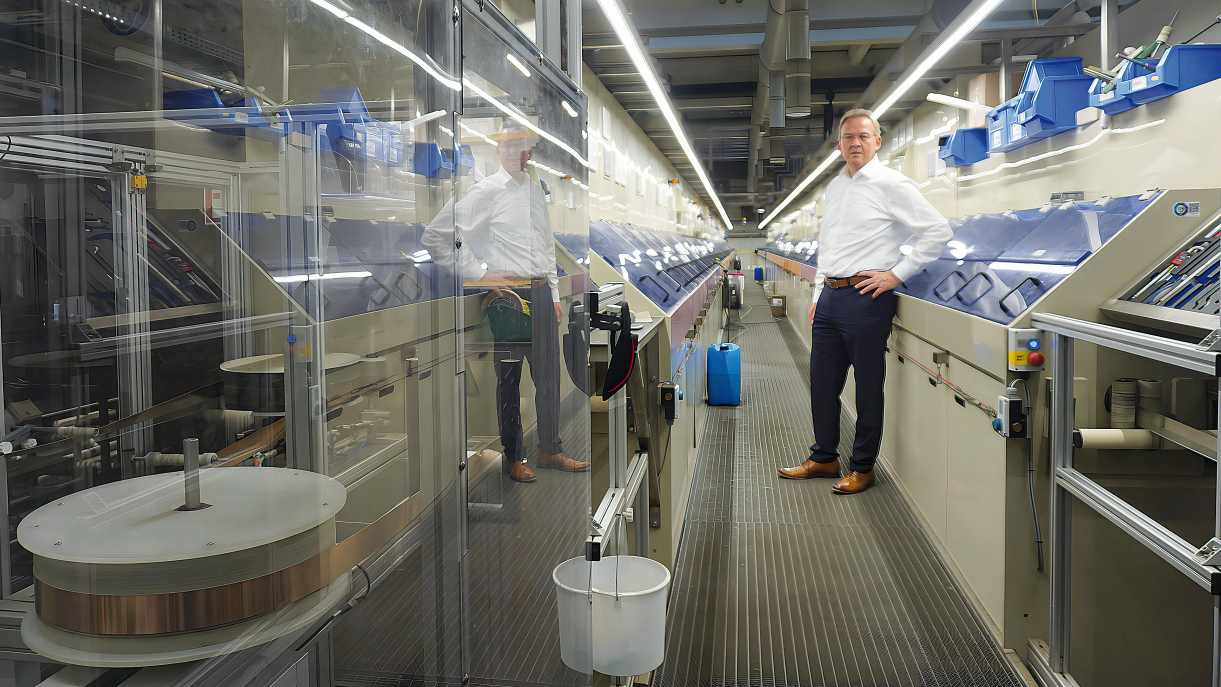

The management team at IMO Oberflächentechnik consists of Kay Müller, René Kühnemund, Thomas P. Henle, Ingo Müller, Bernd Müller and Armin Müller (from left to right)

The management team at IMO Oberflächentechnik consists of Kay Müller, René Kühnemund, Thomas P. Henle, Ingo Müller, Bernd Müller and Armin Müller (from left to right)

Sophisticated masking technology

Another system uses resource-saving spot technology to produce precisely positioned gold coatings by means of selective coating. Here, the strips pass over a special masking module. This ensures that the gold coating is applied exactly at the position specified in the drawing. If a coil of material is coming to an end, the storage technology serves as a buffer to connect a new coil of material to the previous one. Time is required to connect the end and start pieces of a strip, which is gained by the memory. While Karatus joins the ends of the bronze strips by hand, the rollers that guide the strip into the baths lift up, artificially lengthening its path. Time enough for Karatus. This allows the endless belt to continue running without interruption until the job has been completed.

Roller guide of the metal strip on one of the conveyor systems (Photo: IMO Oberflächentechnik)

Roller guide of the metal strip on one of the conveyor systems (Photo: IMO Oberflächentechnik)

Wide range of products

One of IMO Oberflächentechnik's seven production halls is located in Königsbach-Stein between Pforzheim and Karlsruhe. Among other things, connectors for control units, airbags and distance measuring devices in cars are electroplated at the site. Sim card contacts, parts for medical technology, mechanical engineering and current conduction in electric vehicles are also finished here. Around 500 customers with a wide variety of products rely on the Baden-Württemberg-based supplier, which is celebrating its 50th anniversary this year. Gold, silver, tin, nickel, copper and other metals and alloys are used for coating. Around two thirds of the orders are processed in the 32 strip electroplating lines, the rest in the six bulk material machines in drums, vibrating baskets or with racks. The electroplating coil lines are developed in-house and produced in the company's own plant engineering department.

Around 500 customers with a wide variety of products rely on the Baden-Württemberg supplier

Hasim Akmis works on the bulk material system. Here he unloads brass contacts from an electroplating drum

Hasim Akmis works on the bulk material system. Here he unloads brass contacts from an electroplating drum

The company is therefore well positioned. The automotive supply industry, the largest customer sector with around 40 percent, increasingly requires contacts and connectors to conduct electricity to its destinations - to sensors that measure distances and speeds and to various motors that enable numerous functions such as window regulators, the adjustment of exterior mirrors and much more. "The trend is also increasingly moving towards autonomous, self-driving vehicles," notes IMO Managing Director and owner Bernd Müller. "This also requires more cameras and sensors that interrogate each other - which increases the number of connectors," he says, describing one of the reasons for the increased demand for coatings from Königsbach-Stein. Driven by customer demand, IMO Oberflächentechnik has increasingly evolved from coating components for brake assistants, carburetor parts or transmission control units to coating contacts and connectors in the automotive sector, thereby adapting to the expanded needs of the automotive industry.

"The trend is also increasingly moving towards autonomous self-driving vehicles"

If you listen to Bernd Müller, this adaptability is probably also part of the formula for success that has made the company, which the 63-year-old now heads together with Thomas P. Henle, one of the largest electroplating companies in the country and a European technology leader. Over the past 30 years, the company's workforce has increased more than tenfold from around 50 to over 500 employees.

Electricity costs many times higher

A good position on the market is one thing, but the general market conditions are another. And these are a source of irritation for the managers in the northern part of the country. Electricity costs are three to four times higher than in 2019, so the savings from the recent decision to virtually abolish the electricity tax are of little help, explains Thomas P. Henle. Bernd Müller also sees the enormous burden on the electricity-intensive electroplating industry. "All electricity-intensive companies are complaining, whether electroplating or others," says Müller, who joined the company of his father, IMO founder Ingo Müller, in 1980. Added to this are current uncertainties, such as the constitutional court ruling in Karlsruhe, which has triggered a funding gap running into billions. This is now also affecting budgeting for 2024, which is currently in full swing. Finally, sums from the economic stabilization fund that had been factored in are now also potentially in jeopardy.

"All electricity-intensive companies are complaining, whether electroplating or others"

The high cost of electricity and the uncertain economic outlook are having a negative impact on the millions that need to be invested in the company, which is unavoidable for a business of this size. "The screw is turning downwards. We can't save as much energy as we have to pay more for our processes," states Müller. And it is difficult to pass on the increased prices to customers. "Big players are trying to push prices down further and further," Bernd Müller points out. But that's not all: the costs for auxiliary materials and consumables are high and the bureaucracy is constantly increasing. And all this against the backdrop of significantly higher wage increases for employees. The difficult current situation is also not making the required transformation of the industry any easier. Renewable energies, such as geothermal energy, which is possible in the region, will not be available to manufacturing companies for the foreseeable future. The required emission-free factory therefore remains a challenge whose implementation is still in the stars, even if the electricity used currently comes from hydropower, as Thomas P. Henle emphasizes. The manager joined IMO Oberflächentechnik two years ago from a company in the stamping industry.

Compressed air as process support

In electroplating technology, the average energy requirement is significantly higher than the input costs of the manufacturing industry. This is due to the need to keep the baths at a certain temperature around the clock. In addition, IMO has high costs for compressed air and huge exhaust air systems that have to be in constant operation. "When we run solid or stamped strips through the strip electroplating lines, we have to prevent the liquid from moving from one bath to another. This is because the adhesion of the liquid to the strip would carry it away. We strip the strips and also use process air to prevent the baths from mixing," explains René Kühnemund, General Production Manager and member of the Management Board. Separating the baths with the help of process air is important for the service life of the baths and therefore for the economic efficiency of the process.

Addolorata De Leonardis with a so-called busbar, which conducts electricity from the battery to the generator in a car

Addolorata De Leonardis with a so-called busbar, which conducts electricity from the battery to the generator in a car

Kühnemund's career began with an apprenticeship as an electroplater/metal grinder and led him to IMO Oberflächentechnik around 32 years ago after studying to become an electroplating technician and master craftsman at the Solingen technical college. He has witnessed the rapid growth of the large medium-sized company and the switch from manual electroplating to fully automated systems. "You used to need nine to ten employees to do what the automated single-part system can do today," he recalls. He knows from his own experience that automation does not lead to a decline in the number of employees, but rather to growth. Workers from a wide variety of nations now work at Königbach-Stein.

Kühnemund's wealth of experience also includes an experience in 1999 that left a lasting impression on the history of the electroplating company: a devastating major fire that destroyed a considerable part of IMO Oberflächentechnik's plant and equipment. With 18 systems destroyed, the company was on the brink of collapse and had to produce material for customers in Ireland and France in order to maintain its customer base.

In a huge feat of strength, a new factory was built on a greenfield site, where machines were installed around the clock in order to quickly get back on its feet. "That was an incredible feat. We activated all resources worldwide," Bernd Müller looks back today. René Kühnemund also has lasting memories of the exceptional situation at the time.

Focus on the best possible fire protection

The traumatic experience led to exemplary fire protection. "Our seven production halls, each with around 2,000 square meters of production space, are all sealed off from each other in terms of fire protection," describes Kühnemund against a backdrop of humming unwinding noises from running conveyor belts and employees rushing past with pallet-laden pallet trucks. "Today, we have double protection in all heated bathrooms. In future, we will also rely on heating via water circuits," the Head of Production goes into detail, emphasizing that water circuits are the new state of the art for bath heating in electroplating technology. A highly sensitive smoke detection system is also in operation. Also important are the usual safety standards such as the appointment of fire safety assistants and fire safety coordinators as well as the close partnership with the regional fire department.

The traumatic experience led to exemplary fire safety

Meanwhile, in another hall, Hasim Akmis is standing at the terminal of a bulk goods plant. He scans the 3D barcode of the delivered goods, which automatically triggers the stored production process. Akmis follows the production progress on the display and has an overview of the process data. Some time later, a large electroplating drum approaches and stops above a collecting tray. Clamps are released, Akmis turns the drum by hand switch and the electroplated individual parts are unloaded. The brass contacts are nickel-plated and tin-plated. "The single part electroplating works highly productively," explains Kühnemund and reports that the goods are brought directly to the system in the customer's packaging prior to coating, where they are batched, weighed on a roller conveyor, marked with a 3D barcode and finally loaded into the system. After coating, the finished product in the customer packaging is sent directly to dispatch with as little storage time as possible.

Product inspection during production

Passing storage areas marked with QR codes for the customer's raw materials, the route continues to the product inspection area, where a quality inspector is literally putting a coated spring through its paces. He collects retained samples in small plastic bags for archiving. The spring is checked in an X-ray fluorescence measuring device at the measuring points specified by the customer in order to determine the coating thickness. Further tests such as solderability, adhesive strength, ageing tests or bondability are carried out at the customer's request. The many electrolytes, whose basic chemistry comes from specialist companies in the industry, are also regularly tested. A special laboratory, in which five laboratory technicians work, carries out chemical analyses and checks the concentration of the bath ingredients. Test tubes are neatly lined up on racks, behind which the production process can be seen through a viewing window.

Speaking of chemicals: as IMO Oberflächentechnik only uses electroplating, the EU chemicals regulations impose strict requirements here. Product safety and quality as well as legal compliance are very important to IMO. For this reason, an employee is tasked with keeping an eye on developments with regard to environmental regulations.

Finally, nickel is also processed as a base layer, which is classified as an allergen by the EU. However, when it comes to dealing with EU regulations and possible substitutions, the Königsbach-based company mainly relies on the supply industry, i.e. electrolyte and anode manufacturers. As far as chemicals are concerned, the supply of acids and alkalis has at least eased, Henle and Müller agree. Nevertheless: "The chemical companies have used the situation to adjust prices. And prices are no longer going down once they've gone up," Bernd Müller adds seriously. This is an experience that citizens also experience all too often in their daily consumption.

Meanwhile, a tour of the most universal single-part system is on the agenda at the plant. René Kühnemund provides an insight into the modern machine, which can coat rack, barrel and vibrobot products. The multi-talented machine has over 200 bath stations. A rack lifts up and provides a clear view of machine components in rows and rows receiving a tin coating. The system is located in the company's only two-storey factory hall. The goods electroplated here are often used in the e-mobility sector, which already accounts for around five percent of IMO Oberflächentechnik's total business. A particularly important component here is the so-called busbar, a large current-carrying part that connects the battery and generator. IMO Oberflächentechnik also works with research institutes to stay on the ball in future-oriented areas such as these. The Königsbach-based company's main interest here is in coating systems to increase the durability of connectors. However, the company is also involved in topics relating to components with larger dimensions that allow higher currents and the saving of precious metals.

Quo vadis IMO

And where is IMO Oberflächentechnik heading? Maintaining its market position in Europe and securing its location are at the top of the list of priorities. This includes revising processes for sustainability and emission reduction, further healthy growth and, last but not least, securing the next generation of employees. Although the demographic downward spiral can also be felt here in the area between Karlsruhe and Pforzheim, the company is bucking the trend with its own training program. With success: the company currently has 40 trainees - more than ever before in the company's 50-year history.

Photos: Robert Piterek