The JentnerGroup uses RFID technology to control, monitor and document all production processes on its electroplating lines. Initially still in pilot operation, the system impresses with shorter throughput, improved material efficiency and more precise pre- and post-calculation.

Surfaces are of particular importance in almost all areas: medical technology requires unbreakable and abrasion-free instruments that are also resistant to corrosion and heat. As here, there is no room for improvement in the automotive environment or - even more clearly - in the aerospace industry. And from an optical point of view, too, the surface is literally in the foreground.

Optimizing the quality of the finish using electrolytic processes is therefore a general concern. At the same time, the necessary economic efficiency must be taken into account. Only lean, automated and error-free production and QA processes can maintain competitiveness in the long term. Chris Jentner has therefore completely converted his finishing company to RFID (radio frequency identification) technology. The 45-year-old runs his electroplating company of the same name in Pforzheim, which has 60 employees and offers small electroplating equipment and bath chemicals for the jewelry industry, among others, in addition to contract electroplating from small orders to mass-produced goods.

The dawn of digital electroplating

A self-developed production data acquisition system (PDA) has been in use at the site for a good five years. Barcode scanners are used for the largely manual control of production processes. This is now set to change fundamentally: a PHP-based and therefore operating system-independent system for integrating RFID technology is to be introduced. However, the first read/write modules produced for this purpose in the Far East proved to be unsuitable. Problems arose primarily due to the extreme conditions that are common in electroplating. These included high humidity, temperatures of up to 90 °C and handling corrosive acids and alkalis.

In the end, a German supplier took over the development of the required antennas and nodes; the RFID chips for racks and drums also come from there. As a result, it was possible to achieve a greater distance from the production site: Mounted a good half a meter behind the baths, the RFID modules nevertheless ensure very precise and unambiguous detection.

However, an algorithmic solution was found to a problem that arose during test runs, namely the overlapping of radiation windows when process baths were located directly next to each other. The software now uses programmed filter mechanisms to prevent unwanted double detections, ensures precise signal localization and clearly assigns them.

From production data acquisition to evaluation

The system has been running in live operation at a pilot plant since July 2019. The closed workflow begins with rack preparation, where the picker, who is identified by an RFID wristband, can also be identified as the person responsible at a later stage. At his workstation, he first selects a suitable empty rack and scans the order code with a barcode scanner; the relevant articles are displayed. After loading and entering the quantity, the order data is transferred to the RFID tag on the rack, where all the relevant data is stored - the order and rack have been "married" and the picker prints out an accompanying note.

He then logs into the system using an RFID wristband, carries out the required pre-treatments such as degreasing or pickling and initiates the coating processes stored in the order.

In the bath, a rectifier converts the AC voltage into the required DC voltage. The highlight of the RFID-based material flow control: whereas previously a production employee had to set all the parameters using a plan, this delicate process step no longer requires any manual settings. Instead, the RFID tag on the rack or drum provides all the necessary instructions such as volt or ampere values and coating times to achieve the precisely defined coating thicknesses. The rectifier also prevents the flow of current if the values in the bath do not match the order data stored in the tag or if, for example, the bath sequence stored there is to be deviated from for multiple coatings.

"We have merged the bath, antenna and rectifier into a single unit in our system," says Jentner process engineer Marcel Scheidig, summing up the innovation. "This enables us to automatically monitor elementary parameters of the baths such as temperature, conductivity and pH value via sensors and assign them to the racks or drums with their orders." However, Scheidig also sees the high workflow efficiency as a major advantage of the automatic rectifier setting. This means that changing electroplating passes with very different framework conditions can now be mapped in a time-saving manner as if from a single source.

Closed loop with seamless documentation

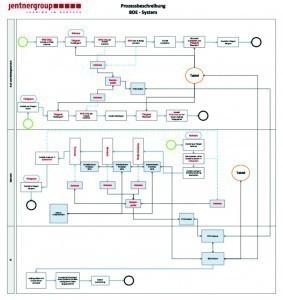

Process description: The PDA workflow at the JentnerGroupInthe final process step, the now fully coated parts are removed from the racks in the same way as the placement process, which is also system-tracked. The collected process data is then transferred to order costing (keyword: post-calculation at the touch of a button), material logistics and quality assurance and used for optimization processes with the close involvement of employees.

Process description: The PDA workflow at the JentnerGroupInthe final process step, the now fully coated parts are removed from the racks in the same way as the placement process, which is also system-tracked. The collected process data is then transferred to order costing (keyword: post-calculation at the touch of a button), material logistics and quality assurance and used for optimization processes with the close involvement of employees.

The digital networking of production processes via RFID has heralded a decisive change at the JentnerGroup. Throughput times have been halved, the use of expensive precious metals has been reduced by twelve percent and delivery reliability has improved by 25 percent. The calculated 18% increase in efficiency is due to system planning and capacity optimization, but also to the minimization of errors. "The system provides us with valuable and detailed insights into our entire value chain," emphasizes Jentner. "The live monitoring and complete documentation of all production steps offer us and our customers a high degree of security that is unique in this form and quality for manual electroplating." Thanks to the system's browser capability, external access is easy via the nearest internet connection.

The next steps

The results have been convincing - which is why Jentner is currently in the process of gradually expanding the live operation of the pilot plant to a total of 120 electroplating tanks and 40 inspection, hanging and QA areas. Including development, the project will have cost him around 750,000 euros by the time the final expansion stage is reached in mid-2020. In addition, the RFID pioneer has already applied for a patent for his process. He is currently looking for partners who will work with him to further develop the system and offer it on the electroplating market.

Jentner's aim is to set an industry standard: No client should settle for less quality and transparency. Ultimately, any hand electroplating company that jumps on the RFID bandwagon could then include a significant competitive advantage in its amortization calculation.

The JentnerGroup at a glance

Founded in 1974 in Pforzheim by Kurt Jentner, the company initially focused on the development of precious and base metal electrolytes. Now managed by Chris Jentner in the second generation since 1999, the company with its 60 employees has also specialized in electroplating for products from various industries.

As part of the JentnerGroup, Jentner Plating Technology GmbH offers all options for optimum surface treatment for jewelers, laboratories and industrial series production with its extensive range. Bath chemicals and small electroplating equipment are also manufactured.

The product range includes colored gold and gold plating baths, bright silver and rhodium baths, palladium and ruthenium baths. But also base metal baths such as copper or nickel. The Profiline, Comfort and Digital electroplating systems round off the range.