Better news at last

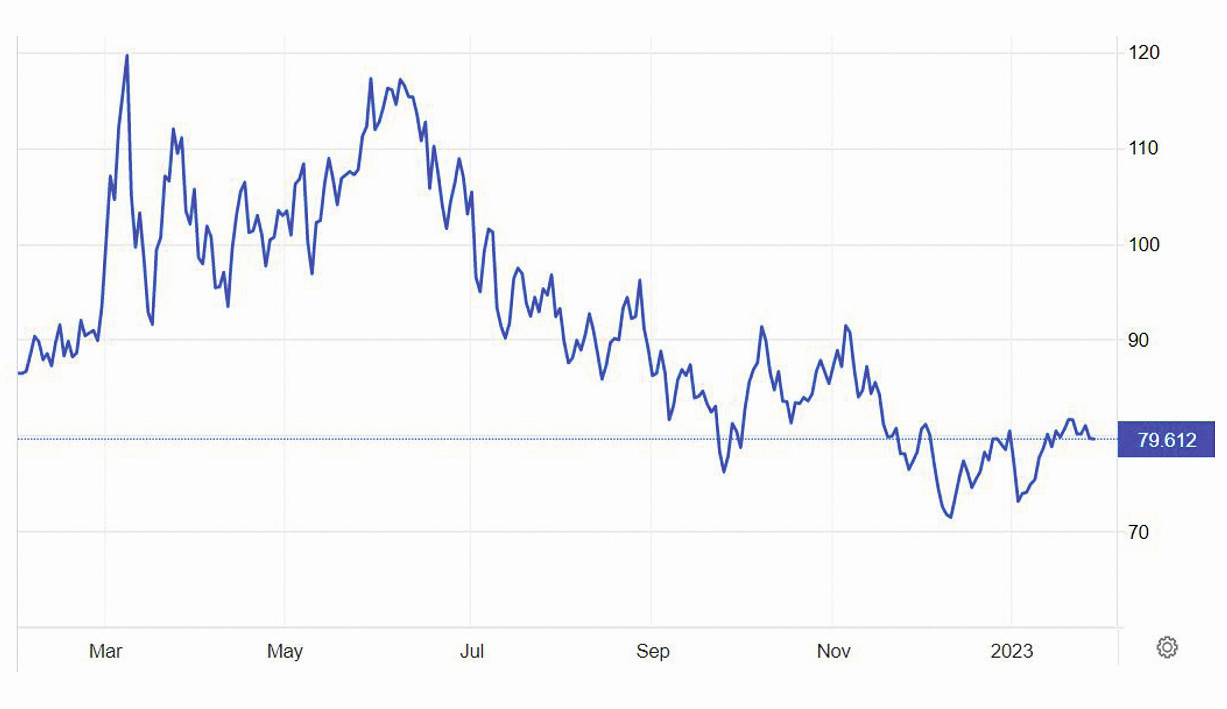

2022 was not a very pleasant year for most of us, but there are some hopeful developments as we head into 2023. Most important for all of us, both in industry and for private individuals, are the signs of falling energy prices. There is no single indicator for global energy prices. However, Figure 1 shows the price of West Texas Intermediate crude oil (US$ per barrel), which is a widely used benchmark.

Fig. 1: West Texas Crude Oil price (Graphic: tradingeconomics.com)

Fig. 1: West Texas Crude Oil price (Graphic: tradingeconomics.com)

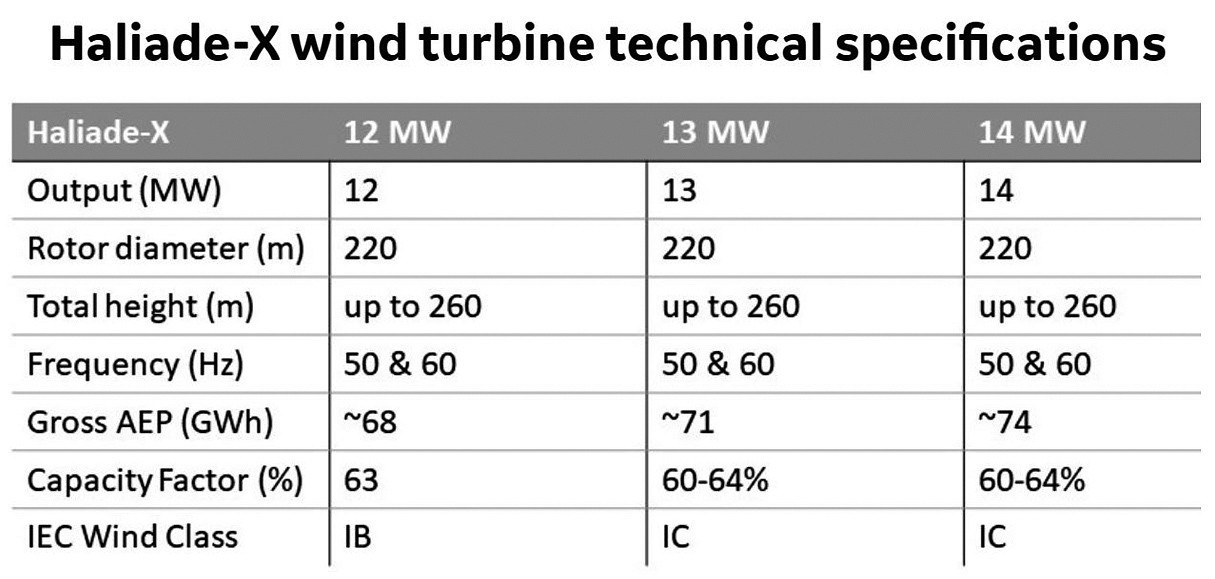

Of course, global energy prices will continue to fluctuate, as they always have, and once China emerges from its pandemic, it will increase its energy consumption and drive up prices. And while fossil fuel prices are currently falling for the time being, renewable energy production is steadily increasing in some European countries. In the UK, the highest wind energy capacity to date was recorded in January 2023 at 21 GW. I don't have data for other European countries, but in the UK, 40% of electricity is now renewable. And that proportion will increase every year this decade as more wind farms come on stream. The importance of the technology, as well as the wind turbines themselves, is growing. The largest wind turbines currently in operation are the Haliade models from GE (USA), whose specifications are shown in Table 1. In short, year on year, we in Europe (and elsewhere in the world) will use less and less fossil fuels. Good news for the environment - not so good news for the oil producers of the Middle East, for Russia and also for Australia and Indonesia, the world's largest coal exporter.

Tab. 1: Technical specifications of the Haliade X wind turbine

Tab. 1: Technical specifications of the Haliade X wind turbine

Rare earths - more good news

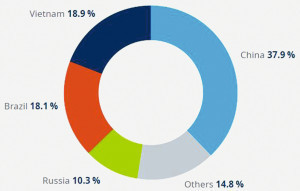

Fig. 2: Known locations of large SE deposits (Source: US Government Geological Survey )As our world becomes more "electric", rare earth (RE) metals are becoming increasingly important. Currently, China is by far the largest producer in the world. Some of its SE exports are mined in China and then refined. Some come from Australia but are sent to China for refining. 98% of the SE metals used in Europe are imported from China. Last year I reported in this space that large deposits of SE metals had been found in Turkey, which was certainly good news. However, under the current political leadership, no one is sure how reliable Turkey is as a partner. Sometimes Turkey leans towards Europe. But at other times it seems to lean on Russia. In short, it is difficult to consider Turkey a "reliable partner". It was therefore very good news when we learned a few weeks ago of the discovery of Europe's largest SE deposit in Kiruna, near the Arctic Circle in Sweden. The discovery was made by the Swedish state-owned mining company LKAB, which already operates the largest iron ore mine in Europe. This is exciting news, although experts have pointed out that it could take 10-15 years before these deposits are actually mined. The general opinion is that SE and lithium will be more important than natural gas and oil in the coming years. Figure 2 shows the main known SE deposits in the world. It does not show any significant SE deposits in Australia or Turkey. In short, it appears that the world will have sufficient SE reserves for electric vehicles, wind turbines, cell phones and many other applications in the foreseeable future.

Fig. 2: Known locations of large SE deposits (Source: US Government Geological Survey )As our world becomes more "electric", rare earth (RE) metals are becoming increasingly important. Currently, China is by far the largest producer in the world. Some of its SE exports are mined in China and then refined. Some come from Australia but are sent to China for refining. 98% of the SE metals used in Europe are imported from China. Last year I reported in this space that large deposits of SE metals had been found in Turkey, which was certainly good news. However, under the current political leadership, no one is sure how reliable Turkey is as a partner. Sometimes Turkey leans towards Europe. But at other times it seems to lean on Russia. In short, it is difficult to consider Turkey a "reliable partner". It was therefore very good news when we learned a few weeks ago of the discovery of Europe's largest SE deposit in Kiruna, near the Arctic Circle in Sweden. The discovery was made by the Swedish state-owned mining company LKAB, which already operates the largest iron ore mine in Europe. This is exciting news, although experts have pointed out that it could take 10-15 years before these deposits are actually mined. The general opinion is that SE and lithium will be more important than natural gas and oil in the coming years. Figure 2 shows the main known SE deposits in the world. It does not show any significant SE deposits in Australia or Turkey. In short, it appears that the world will have sufficient SE reserves for electric vehicles, wind turbines, cell phones and many other applications in the foreseeable future.

And lithium?

Aside from SE elements, the other key element for an all-electric future is lithium. This vital element is found in two forms - as a component of hard rock and also in aqueous brines. Latin America has the largest reserves in the world - Bolivia with an estimated 21 million tons, Argentina with 17 million tons, Chile with 9 million, the USA with 7 million, Australia with 6 million and China with 4.5 million. Zimbabwe and Portugal also have known reserves. Lithium-bearing ores are also widespread in Europe, including Germany and Austria. The only deposit close to commercial exploitation is the Jadar area in Serbia, where Rio Tinto is active. The Jadar area is estimated to contain 10% of the world's known lithium, but the project faces fierce local opposition and its future is uncertain. In December 2022, Serbian Prime Minister Ana Brnabic appeared undecided on whether to proceed with the project. It would be good for the Serbian economy, but local residents are still vehemently opposed. There are significant lithium deposits in Cornwall, in the west of England, and two companies - British Lithium and Cornish Lithium - are developing plans to extract the metal. But as with all mining projects, the future is uncertain.

Beneath our feet

Up to one million kilometers of water pipes run through both England and Germany. Unfortunately, they also have thousands of leaks, through which millions of liters of precious water are lost every year. Until recently, the technology for finding leaks was relatively primitive, using acoustic devices that respond to the sound of escaping water, for example. However, waterworks are now developing a new type of robot - the so-called "pipebot" (Fig. 3). These are autonomous devices that can move through water pipes and report on the condition of the pipes and any leaks. An artificial intelligence specialist, Prof. Netta Cohen from the University of Leeds, explains: "We will need a lot of these robots to be able to work in the kilometers of pipes". The biggest challenge is communication. "There is no GPS underground. So the robots will have to communicate with each other over short distances (via sound or wifi). Professor Cohen and her colleagues are developing a system in which a larger "mother robot" carries and deploys a group of miniature robots. "You drop these little pipebots off to go into the smaller pipes and collect them when they're done." The development team from ICAIR (Integrated Civil and Infrastructure Research Centre) at the University of Sheffield hopes to have the first pipebots patrolling the water network within five years. Until then, every time a leak occurs, the water companies will have to search through the labyrinth of sewer pipes, gas pipes and cables to repair it. https://icair.ac.uk

The future of agriculture

Fig. 4: Robotic harvesting of broccoli (Photo: Upp Ltd)If you could magically "beam" a 19th century farmer to today's farms, much of what he sees would look very familiar. The only thing he would notice is that there are no horses - and instead a brightly colored "iron horse" - a tractor. But agriculture today is on the verge of a revolution. We are observing two different developments. On the one hand, the construction of huge glass greenhouses in which plants are grown without soil in an optimized climate. And on the other hand, traditional fields where sowing, planting and harvesting are automated. Many traditional farmers have been suffering from the same problem for a long time. Most of the year, they only need one or two farm workers. But when it's harvest time, especially for vegetables, they need a whole team of workers - but only for a few weeks. And in large parts of Europe, it is becoming increasingly difficult to find such people. In the former Soviet Union or in China, the problem was easy to solve. Students, soldiers and other young people were forced to work in the fields for perhaps a month every summer. But today, dozens of companies are developing automated machines for harvesting crops.

Fig. 4: Robotic harvesting of broccoli (Photo: Upp Ltd)If you could magically "beam" a 19th century farmer to today's farms, much of what he sees would look very familiar. The only thing he would notice is that there are no horses - and instead a brightly colored "iron horse" - a tractor. But agriculture today is on the verge of a revolution. We are observing two different developments. On the one hand, the construction of huge glass greenhouses in which plants are grown without soil in an optimized climate. And on the other hand, traditional fields where sowing, planting and harvesting are automated. Many traditional farmers have been suffering from the same problem for a long time. Most of the year, they only need one or two farm workers. But when it's harvest time, especially for vegetables, they need a whole team of workers - but only for a few weeks. And in large parts of Europe, it is becoming increasingly difficult to find such people. In the former Soviet Union or in China, the problem was easy to solve. Students, soldiers and other young people were forced to work in the fields for perhaps a month every summer. But today, dozens of companies are developing automated machines for harvesting crops.

A British broccoli harvester is claimed to be able to replace seasonal workers in the fields and utilize 80% more of the harvest. The company Upp has developed a robot that is mounted on a tractor (Fig. 4).

It uses 3D cameras and artificial intelligence to recognize broccoli heads that are ready to be picked. It can do this even if they are covered with leaves. It carefully separates the heads from the plant. Unlike humans, the vehicle developed by Upp can work around the clock in the fields. The robot processes the rest of the broccoli plant, i.e. the 80% that would normally rot in the field, into vegetable protein that can be used in alternative meat and food products, generating additional income for the farmer. Upp will be testing the technology over the next year in collaboration with farms in the UK, the United States and Spain.

Further details and a video can be found at https://www.upp.farm/home. Similar projects are currently underway for all crops from potatoes to strawberries.

Rare earths - right?

I've already reported on the discovery of huge SE deposits in Sweden. But can we make the powerful magnets used in wind turbines and electric vehicles without SE elements? The search for high anisotropy alloys that do not contain SE is underway. Dr. Carl Zhuang Wang and his colleagues at the U.S. Department of Energy's Ames Laboratory are using AI and density functional theory (DFT) to find promising alloys. So far, they haven't found a compound equivalent to an SE magnet, but they have shown that their approach works, and their magnets made from an alloy of iron, cobalt and boron are getting better and better. They believe that a powerful FeCoB magnet is within reach, and if they succeed, it will have a huge impact on electric vehicles and other devices.

W Xia et al Proc National Acad Science USA (2022) vol 119 e2204485119. DOI 10.1073/pnas2204485119

Autonomous transportation

Self-driving cars and trucks have been under development for several years. And more recently, ships and even airplanes! In some cases, the driving force is cost savings. But it is also argued that automated transportation - thanks to human error - can actually be safer than vehicles under human control. A Japanese cargo ship, the MV Suzaku (95 m long, weighing 749 t), was sent on an 800 km journey in busy shipping lanes without a crew last year, taking a significant step forward in the race to realize fleets of unmanned ships. A consortium led by Nippon Yusen, the country's largest shipping company, created an autonomous ship that traveled from Tokyo to the port of Ise in central Japan and back to Tokyo. It was remotely controlled using satellite technology, on-board sensors and artificial intelligence.

Japan is not alone in developing this technology. In 2018, an autonomous ferry developed by Rolls-Royce made a kilometer-long crossing between two islands in Finland. According to Nippon Yusen, this was the first test of an autonomous ship in an area with heavy shipping traffic. About 70% of accidents at sea are due to human error, so unmanned ships could be safer. With Japan's shrinking working population, there is a growing need for such technology to ensure safety. For more details about the project and the various Japanese organizations involved, visit:

https://www.nippon-foundation.or.jp/en/news/articles/2022/20220301-67775.html

And now - autonomous airplanes

Fig. 5:. The unmanned cargo drone from DronamicsToget straight to the point: In recent years, there have been numerous autonomous drones that have taken on tasks such as delivering parcels or, in some cases, even transporting passengers. However, these are aircraft without wings that take to the air with the help of horizontal rotors - a far less efficient process than aircraft with wings. Two brothers in Bulgaria, the Rangelovs, have founded the company Dronamics. Their drones are winged aircraft (Fig. 5).

Fig. 5:. The unmanned cargo drone from DronamicsToget straight to the point: In recent years, there have been numerous autonomous drones that have taken on tasks such as delivering parcels or, in some cases, even transporting passengers. However, these are aircraft without wings that take to the air with the help of horizontal rotors - a far less efficient process than aircraft with wings. Two brothers in Bulgaria, the Rangelovs, have founded the company Dronamics. Their drones are winged aircraft (Fig. 5).

The drone, which looks very similar to a conventional lightweight aircraft but has no pilot's cabin, combines "cell phone economy" in the form of cheap electronics with the ability to land on short runways, says Mr. Rangelov. It will be known as the Black Swan. In most countries, air freight means transferring goods from a large aircraft to a truck, which then travels to a sorting center where the shipment is split up for the next leg of its journey to individual locations. Dronamics believes that moving a smaller load to a short runway closer to the final recipient reduces costs and takes trucks off the road. There are 3,000 runways across Europe that could be used in this way. The Black Swan is made from a combination of lightweight composite materials and a standard gasoline piston engine. The aircraft is designed to fly at an altitude of approximately 7000 meters, lower than most civilian passenger air traffic. Dronamics considers this altitude range to be unused airspace and is also testing a new synthetic jet fuel that is claimed to enable carbon-neutral flights. The Black Swan's 350 kg load is equivalent to that of a small courier vehicle. Dronamics' philosophy is to fly from city to city, not door to door.

Dronamics plans to operate Black Swans like an airline, "Europe's first drone cargo airline". Billing will be based on weight or charter, eliminating the cost and time of vehicles criss-crossing Europe.

At least one German company is interested

German logistics giant Hellmann wants to use these drones to connect Greek islands. Jan Kleine-Lasthues, who is responsible for this initiative, has a long career in air freight behind him. He does not see conventional air freight competing with these new concepts, but believes that the drones will enable Hellmann to transport goods that were previously transported by road. Connecting the Greek islands by cargo drone is one of Hellmann's immediate goals, says Kleine-Lasthues. The drones will be more frequent than ferries, and we can use them to split deliveries into multiple parcels so that we can increase the frequency of deliveries. They are a big change, they offer speed and flexibility.

Dronamics claims its aircraft has a range of 2500km, which puts the whole of Western Europe within reach of any EU-based cargo hub. Smaller versions of the drone are already in use in Bulgaria, with a full-scale prototype due to be in the air in the next few months.

According to Dronamics, the European aerospace regulator has been informed of the planned operations and has granted the company a limited operating license. Hellmann is talking about starting flight operations this year.

Plastic waste - a solution?

Plastic waste is a problem in every country in the world (and in the oceans). There are many proposals to solve this problem. Some European countries simply ship their plastic waste to Turkey, Africa or India - without knowing what happens to it there. Most processes are based on an initial sorting of the plastic waste into certain types of polymer, some of which can simply be melted down again and thus recycled. However, such sorting, even when carried out by machines that use infrared beams to identify the different polymers, is expensive and slow. A slightly less elegant solution is now being built in England and Scotland by Powerhouse Energy(www.powerhouseenergy.co.uk). In the DMG process, the plastic waste is shredded into small chips and then fed into a thermal reactor. This converts it into so-called Syngas - a mixture of hydrogen, methane and carbon monoxide. No external heating is required - the process is exothermic. The syngas can be used as fuel, or the hydrogen can be separated for use in fuel cells to generate electricity. Two plants are currently under construction, each processing 13,500 tons of mixed plastic per year. For comparison: Scotland alone, with a population of over 5 million, produces 222,000 tons of plastic waste per year. A country like England or Germany would need around 100 such plants to cope with the amount of plastic waste.

Alternative approach

Researchers at the University of Cambridge have developed a solar-powered reactor that converts plastic waste andCO2 into sustainable fuels and other valuable products - an advance that supports the development of a circular economy. The system converts two waste streams into two chemical products simultaneously. This is the first time this has been achieved in a solar-powered reactor. The reactor converts carbon dioxide and plastics into various products that are useful in a range of industries. In tests,CO2 was converted into synthesis gas, an important building block for sustainable liquid fuels, and plastic bottles were converted into glycolic acid, which is widely used in the cosmetics industry. According to the university, the system can be adapted to produce different products by changing the type of catalyst used in the reactor. Converting plastics and greenhouse gases into useful and valuable products using solar energy is an important step towards a more sustainable circular economy.

Other solar-powered "recycling" technologies show promise when it comes to tackling plastic pollution and reducing the amount of greenhouse gases in the atmosphere, but so far they have not been combined into a single process. "A solar-powered technology that could help tackle plastic pollution and greenhouse gases at the same time could be a game changer for the development of a circular economy," says Subhajit Bhattacharjee, the lead author of the study.

Subhajit Bhattacharjee, Motiar Rahaman et al. 'Photoelectrochemical CO2-to-fuel conversion with simultaneous plastic reforming.' Nature Synthesis (2023). DOI: 10.1038/s44160-022-00196-0

Lead is not dead

There is news about lithium batteries almost every day. You might think that these are the only batteries on the market. But quietly, the traditional lead-acid battery continues to serve many applications in forklift trucks, backup power for computer systems and more. And there have been significant advances in lead-acid battery technology. A new generation of lead-acid batteries is said to have a longer life (up to 1500 charge/discharge cycles), 50% faster charging time and higher energy density. This new generation of batteries uses carbon nanotubes containing a gel electrolyte. They are marketed under names such as "Quasar Gel Block" by companies such as Eternity Technologies, an American company with branches in France, Spain and other countries. Triathlon Batterien GmbH in Glauchau is also likely to offer a similar technology.

Producing solar cells

Researchers have demonstrated a new way to produce stable perovskite solar cells that have fewer defects and the potential to rival the durability of silicon. By eliminating the solvent dimethyl sulfoxide and introducing dimethylammonium chloride as a crystallization agent, researchers at Oxford University and Exciton Science were able to better control the intermediate phases of the perovskite crystallization process, resulting in higher quality thin films with fewer defects and greater stability. Up to 138 sample components were subjected to accelerated ageing and testing at high temperatures and under real conditions.

Formamidinium-caesium perovskite solar cells produced using the new synthesis process are said to have significantly outperformed the control group and proved resistant to thermal, moisture and light degradation. Perovskite-silicon tandem devices could thus become the dominant solar cell of the next generation. Tests showed that the solar cells took 1,400 hours under simulated sunlight at 65 °C to degrade to 80 % of their original efficiency - longer than conventional cells. After 1,600 hours, the control device produced using the conventional dimethyl sulphoxide process stopped working, while the devices produced using the new design retained 70 % of their original efficiency under accelerated ageing conditions.

D P McMeekin et al. Nature Materials, vol. 22, pp. 73-83 (2023)

https://doi.org/10.1038/s41563-022-01399-8