Counterfeit-proof surfaces are one way of countering increasing product piracy. The aesthetics must also be right. Laser marking, pad and digital printing are used.

We have developed a completely new software solution for the camera-supported automatic quality control of printed industrial products that can be freely configured by the user," says Roman Haller, Project Manager at Compar AG in Pfäffikon SZ, Switzerland. The engineering company has been active in the field of industrial image processing for almost 35 years and works for numerous well-known industrial customers in Switzerland and abroad. It serves virtually all high-tech sectors such as pharmaceutical and medical technology, watchmaking, the automotive and electronics industries, as well as toy manufacturers. Based on the know-how gained from the development of countless complete quality control systems for all kinds of printing processes and products, the VisionExpert Optical Print Inspection tool is a software package with almost universal application possibilities. Previously, such solutions had to be developed by external experts for just one application or for a limited range of closely related applications. The new tool, on the other hand, enables users to configure their own solutions for a wide range of different applications or new products. A powerful function library is available to them, with the help of which even demanding tasks can be mastered.

While minor pigment defects within the individual color areas (left and center) can be tolerated up to a certain degree, they become a rejection criterion above a predefined threshold (right)

While minor pigment defects within the individual color areas (left and center) can be tolerated up to a certain degree, they become a rejection criterion above a predefined threshold (right)

The automated optical inspection of printed images is by no means a simple matter for which you only need a few good/bad comparison images, adds Haller. In reality, the requirements are often very complex because the devil is usually in the detail. This starts with the almost unmanageable variety of processes used and the products to be printed. Another important factor is determining the tolerances of what can and cannot be accepted. In addition, the range of quality specifications varies enormously depending on the area of application. At the top of the list of requirements are sectors such as the pharmaceutical and watchmaking industries, where deviations in the range of hundredths of a millimeter are sometimes considered a reject criterion. Other sectors such as toy or packaging manufacturers are often much more tolerant in this respect. Here, on the other hand, other criteria such as aesthetics or product appearance often have to be taken into account.

Comprehensive library for a wide range of application solutions

Comprehensive library for a wide range of application solutions

In addition to the question of pure contour sharpness, it is also about color deviations, uniformity of the ink application or distortion of the printed image. The latter depend in part on the printing process. For example, pad printing results in different widths of the elastic printing stamp depending on the contact pressure. Geometry variations in two- or three-dimensionally curved objects or temperature-related dimensional changes at the moment of printing can also lead to distortions. Due to this diversity, the development of automatic control systems has almost always required the creation of customized hardware and software tailored to the customer's needs.

However, quality control must also be economical. Excessive demands can result in unacceptably high reject rates. In addition, the peculiarities of the process used must always be taken into account. With laser printing, for example, undesirable burn-in on the surface of the parts is possible. In digital printing with inkjet print heads, neighboring droplets can flow into each other, and distortions or accordion effects are often to be expected when printing on curved surfaces.

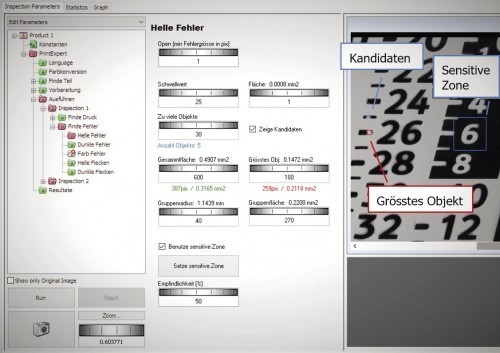

However, VisionExpert also solves complex tasks such as taking distortions into account, e.g. with flexible materials such as foils or textiles. The use of masks to mask out interfering environmental information such as fixtures or the inspection of certain areas for stains or splashes is also solved. If necessary, aesthetics can also be given priority over perfection, for example in toys, where minor defects can be tolerated as long as they do not disturb the eye.

A real highlight, for example, is the ability to check the print on areas of a product that are only partially visible behind a cut-out in the packaging. The software recognizes which section of the print image is involved and only checks the visible area for errors. Examples of such applications are jigsaw blade assortments or products with a scale in sales packaging made of printed cardboard. Another advantage of VisionExpert is the fact that Compar has extensive experience with tasks in the field of high-precision optical measurement down to the nanometer range. In such applications, this expertise can help to avoid unnecessary product losses as a result of excessively tight tolerance specifications.

"When designing the software, the focus was on making it as user-friendly as possible," emphasizes Roman Haller. In principle, it bundles software modules from a large number of previously implemented developments, which can be accessed using a simply structured user interface. The package can be operated without any special prior knowledge and can be quickly and easily configured for a wide range of applications thanks to the module libraries available in the background. It can therefore be adapted to other printing processes or products at any time. Hierarchically graded access authorizations allow pre-defined employees to teach in new or modified image patterns, e.g. when unforeseen error categories occur or when teaching in new products. This allows it to be flexibly adapted to the existing personnel structure in the respective company. If required, VisionExpert can also be used to expand its range of functions to include additional image processing topics such as measurement, position control, etc. And last but not least, if required, it is backed by the many years of consulting and problem-solving expertise of a company that has been active in the field of computer-aided image processing for decades.