The occurrence of harmonics in AC supply networks has been known for years and has been the subject of many publications. Recently, however, the topic has increasingly come into focus.

The effects of harmonics in electrical supply networks have a noticeable impact on the manufacturing industry, for example. In industrial grids in particular, harmonics can lead to the failure of electrical consumers and thus to an impairment of the production process. Harmonics are constantly present in industrial electrical networks, but are often not recognized as critical. A frequent cause of harmonics is the use of non-linear loads in modern production processes. These include, for example

- Frequency converters for electrical drives

- Switch-mode power supplies for lighting (LED/energy-saving lamps)

- Battery charging systems

- IT systems etc.

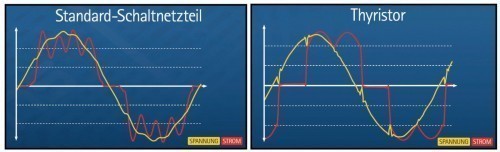

Fig. 1: Current and voltage distortion with passive rectification - typical curves

Fig. 1: Current and voltage distortion with passive rectification - typical curves

The use of non-linear loads brings tangible benefits for the user. The high electrical efficiency combined with low energy consumption should be emphasized here. Further advantages of using rectifiers with switching power supply technology are the low residual ripple and high control accuracy. However, the use of these non-linear loads leads to a distortion of the ideal, sinusoidal mains current or voltage.

Harmonics in conjunction with (galvanic) rectifiers

In principle, switching power supply or thyristor-based rectifiers with passive rectification generate harmonic currents. These lead to a non-sinusoidal current draw (distortion) which can be measured as a grid reaction.

Parameters for assessing the power quality

In practice, the total harmonic distortion of the current (THDI) or voltage (THDU) is used to assess the quality of a supply network. All harmonic currents generated in a network must flow through the existing impedances and all other parallel branches, which leads to non-linear voltage drops at the impedances. The resulting harmonic voltages spread across the entire network and affect the quality of the supply voltage to other devices. As a result, the harmonic distortion of the current is a cause of the voltage distortion.

Technical measures to compensate for harmonics

Conventional harmonic filters are installed close to the load and generate a compensating current to reduce harmonics in an electrical supply system. In the overall system view, harmonic filters reduce the system efficiency due to the additional voltage drop at the filter.

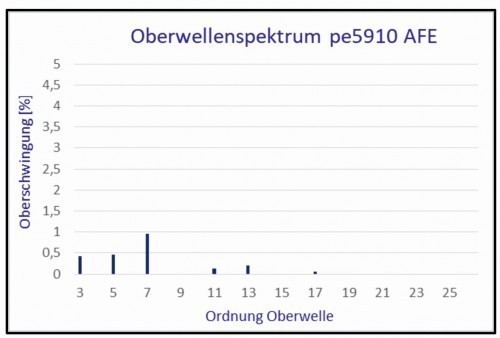

Another alternative for reducing harmonics in an electronic supply network is the use of loads with active rectification, so-called Active Front End (AFE) technology. These loads behave like a resistive load in the electrical supply system, i.e. the current draw is sinusoidal. With the POWER STATION pe5910-AFE rectifier cabinet from plating electronic, a rectifier with active rectification with 230kW DC or 10,000A is now available on the market for the first time. The integrated AFE technology in the rectifier leads to a significant reduction in current harmonics and an improvement in efficiency.

Fig. 3: Harmonic spectrum POWER STATION pe5910-AFE at 200 kW DC power

Fig. 3: Harmonic spectrum POWER STATION pe5910-AFE at 200 kW DC power

Users benefit from the following advantages by using rectifiers with AFE technology:

- Sinusoidal current draw prevents voltage distortions, no harmonic compensation required for rectifier operation

- Increase in the power factor from 0.95 to 1.00

- THDI reduction to less than 3

- Reduced phase current due to sinusoidal current drain, i.e.

- Lower load on the supply transformer

- Reduced transformer dimensioning for rectifier operation

- High efficiency of up to 96 % thanks to active rectification (AFE technology)