FDM-ABS plastics - electroless copper plating

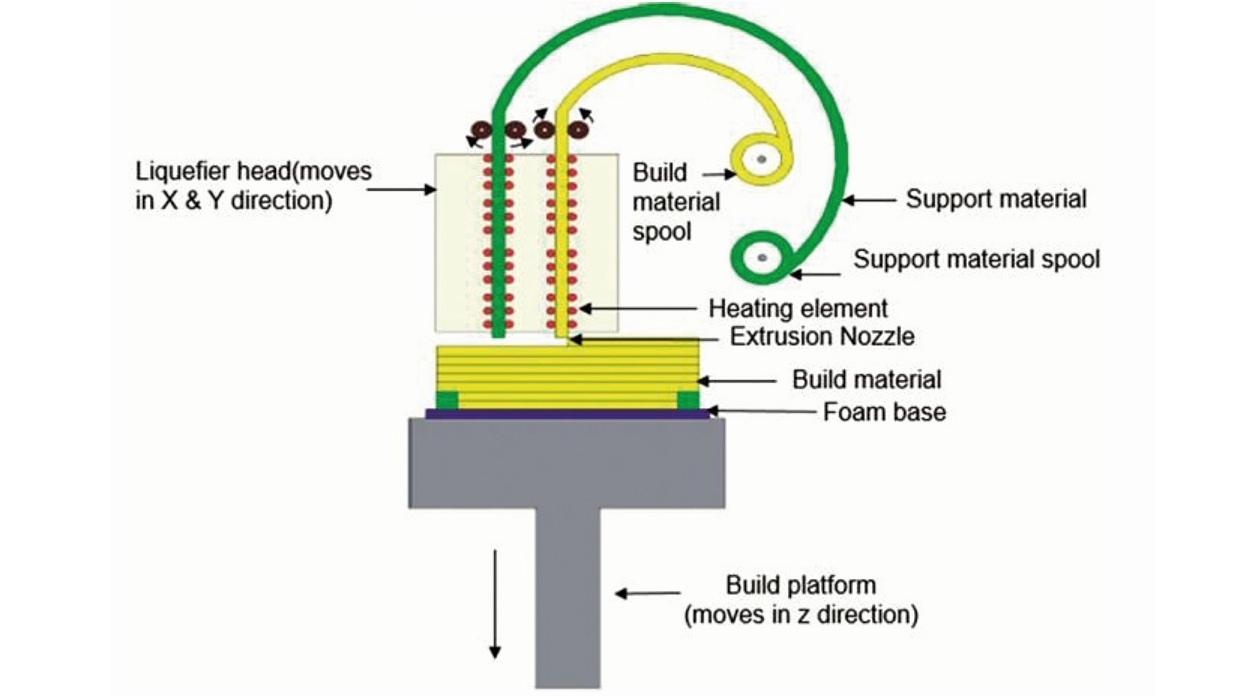

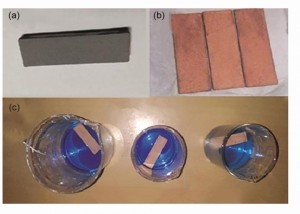

Metallization process: (a) ABS samples for the experiment after Al-C enamel paste application (b) electroless copper-plated FDM-ABS parts and (c) view of the baths Fused Deposition Modeling (FDM) is one of the most commonly used additive manufacturing processes. It is an extrusion process in which physically or chemically prepared solid starting materials such as plastics, pastes or foams are melted from the solid phase and processed. The most commonly used thermoplastic, printable materials for the FDM process are acrylonitrile butadiene styrene (ABS), polylactic acid (PLA) and polycarbonate (PC).

Metallization process: (a) ABS samples for the experiment after Al-C enamel paste application (b) electroless copper-plated FDM-ABS parts and (c) view of the baths Fused Deposition Modeling (FDM) is one of the most commonly used additive manufacturing processes. It is an extrusion process in which physically or chemically prepared solid starting materials such as plastics, pastes or foams are melted from the solid phase and processed. The most commonly used thermoplastic, printable materials for the FDM process are acrylonitrile butadiene styrene (ABS), polylactic acid (PLA) and polycarbonate (PC).

The individual filaments are solidified during the cooling process by evaporation of solvents or by chemical reaction and at the same time ensure that the materials stick together. In recent years, the FDM process has become particularly popular with desktop printers for home users. In addition, the number of materials, colors, material properties and service providers is increasing rapidly. FDM is used in the automotive industry and ranges from test models and lightweight tools to final functional components.

At the National Institute of Technology Rourkela, India, engineers have developed a process for electroless copper plating of FDM ABS plastic.

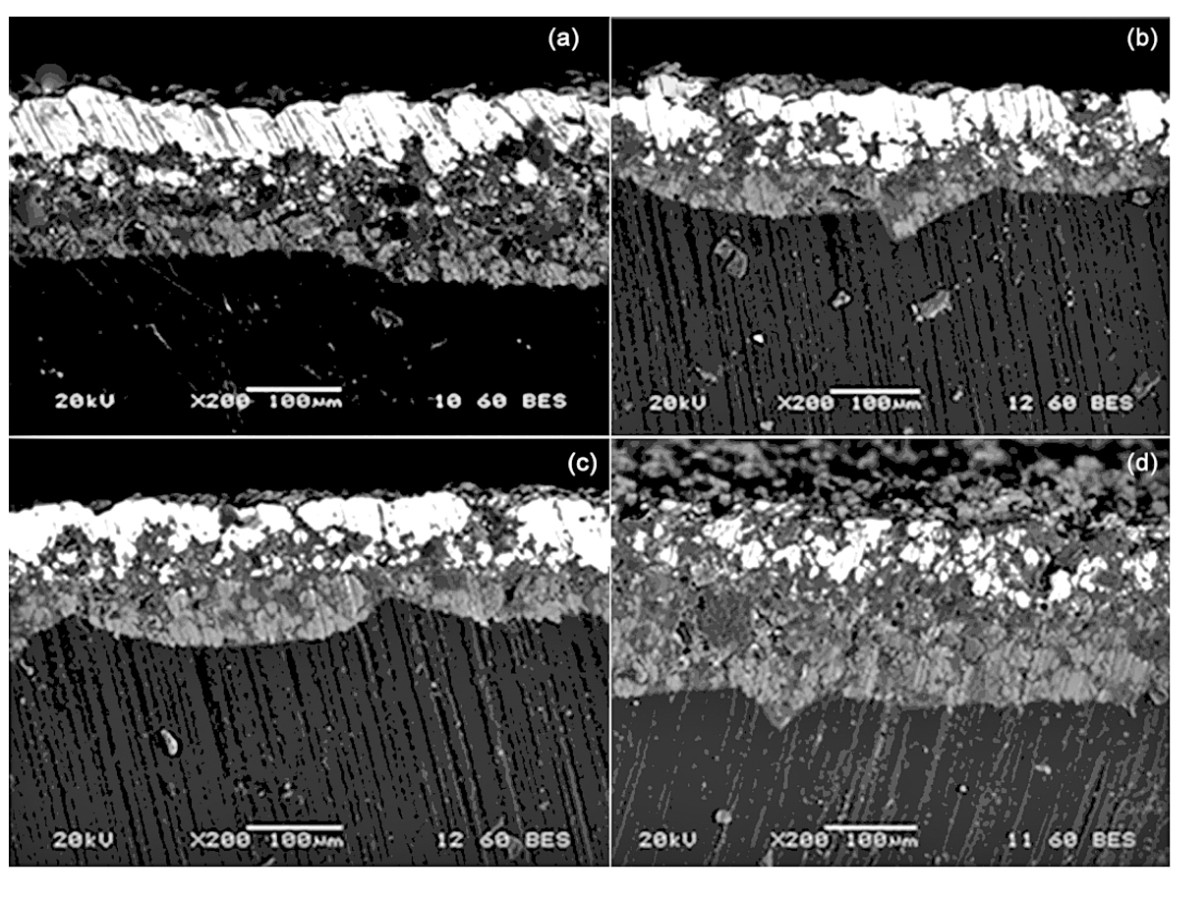

Four acid baths containing five percent by weight of HF, H2SO4, HNO3 or H3PO4 were used for metallization, with copper sulphate (CuSO4) in each bath at 10, 15 and 20 percent by weight. The metallization process was continued for seventy-two hours in each bath. The copper layer was characterized. Scanning electron microscopy (SEM) and energy dispersion X-ray spectroscopy (EDX) results showed that all baths were quite capable of depositing copper on ABS substrates with good adhesion. The HF bath showed better coating performance. The coating thickness and the percentage of copper in the coating were highest when using the HF bath with fifteen percent CuSO4 by weight.

SEM image of the Cu coating (a) 15 % HF, (b) 10 % H2SO4, (c) 10 % H3PO4, and (d) 20 % HNO3.

SEM image of the Cu coating (a) 15 % HF, (b) 10 % H2SO4, (c) 10 % H3PO4, and (d) 20 % HNO3.

To activate the FDM-ABS substrate surface, an Al-C enamel paste in water (40:3:36:21% by weight) was applied directly to the surface of the ABS parts, eliminating the need for etching, neutralization, activation and acceleration. After copper plating, the parts were heated at 65 °C for 30 minutes. It was found that the coatings produced with all baths exhibited good electrical conductivity with uniform copper deposition, with the exception of the HNO3 bath, which resulted in over-etching of the aluminum particles in the presence of HNO3. In the experiments, the layer thickness was between 41 and 80 μm. The method developed is relatively more environmentally friendly. Statistical analysis of the process is carried out using ANOVA to determine the influence of process parameters and to optimize the process.

Indian J. Eng. Mater. Sci. 2021, 28, pp. 174 - 181; ibid. pp. 300 - 310

Cr6+-free anodization of aluminum

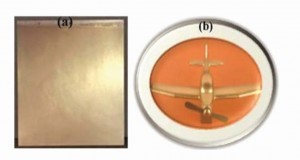

(a) Anodized and sealed AA 2024 sheet and (b) aircraft step-down modelAnodizingwith chromic acid (Cr6+) is often used for corrosion protection of aluminum alloys for aircraft. Scientists and engineers from four laboratories in Bengaluru have developed a new process without Cr6+- that appears to be promising. In the study, a modified tartaric acid-sulfuric acid (TSA) process followed by sealing in a permanganate-based bath was developed to obtain a 4 to 6 µm thick anodic oxide layer on aluminum alloys 2024-T3, 6061-T6 and 7075-T6. The process was tested in an anodizing plant on a 400 liter pilot scale. The anodized samples were tested for their optical properties, coating thickness, adhesion, dielectric breakdown voltage, corrosion resistance and tensile strength according to MIL-A-8625F.

(a) Anodized and sealed AA 2024 sheet and (b) aircraft step-down modelAnodizingwith chromic acid (Cr6+) is often used for corrosion protection of aluminum alloys for aircraft. Scientists and engineers from four laboratories in Bengaluru have developed a new process without Cr6+- that appears to be promising. In the study, a modified tartaric acid-sulfuric acid (TSA) process followed by sealing in a permanganate-based bath was developed to obtain a 4 to 6 µm thick anodic oxide layer on aluminum alloys 2024-T3, 6061-T6 and 7075-T6. The process was tested in an anodizing plant on a 400 liter pilot scale. The anodized samples were tested for their optical properties, coating thickness, adhesion, dielectric breakdown voltage, corrosion resistance and tensile strength according to MIL-A-8625F.

The samples were also subjected to real time corrosion test for about 800h at Mandapam Camp, Rameshwaram, 200 meters from the sea shore. The performance of the permanganate-sealed TSA-anodized aluminum alloys was comparable to that of conventional chromic acid anodized coatings. The developed chromic acid-free anodizing process was found to be airworthy by the Indian military certification authorities. Work is currently underway to commercialize this technology for use on aerospace platforms.

Indian J. Eng. Mater. Sci. 2021, 28, pp. 21-27

Miscellaneous

Novo Precision LLC, a Bristol, Conneticut-based manufacturer of industrial, medical and machined components and systems, has acquired Bristol-based Core Plating Technologies, a manufacturer of plating drums, tanks and components for the metal finishing industry

Chinese IT product manufacturer DBG Technology has confirmed that it will set up new production lines in Bangladesh following its success in India and Vietnam. DBG's main products include mobile devices, ICT products, IoT, automotive electronics and wearables. Cell phones and tablets are DBG's largest source of revenue.

The South Indian group TVS will invest 160 million US dollars over the next four years in the production of future cars and electric vehicles. TVS Motors is thus transforming itself into a sustainable, electric and digitalized manufacturer. The investment will be used to develop and manufacture new products and expand production capacity for electric vehicles. The two-wheeler manufacturer has also received licenses from 24M Technologies for the production of Li-ion batteries in India. Apart from TVS, Indian EV startup Ola Electric, scooter manufacturer Hero MotoCorp and Bajaj Auto, among others, have also invested in the development of electric two-wheelers.