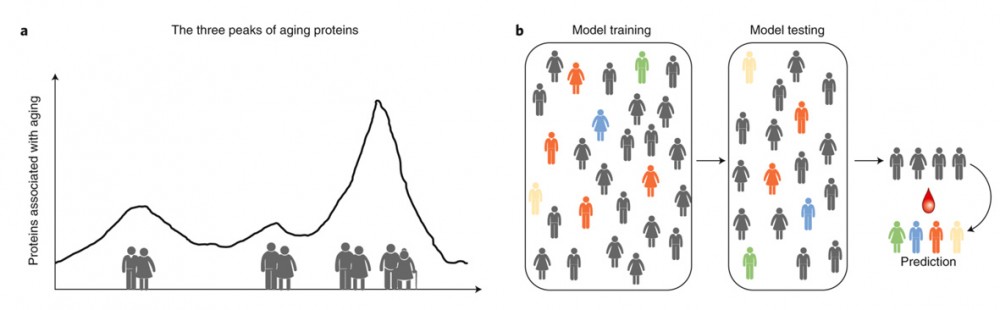

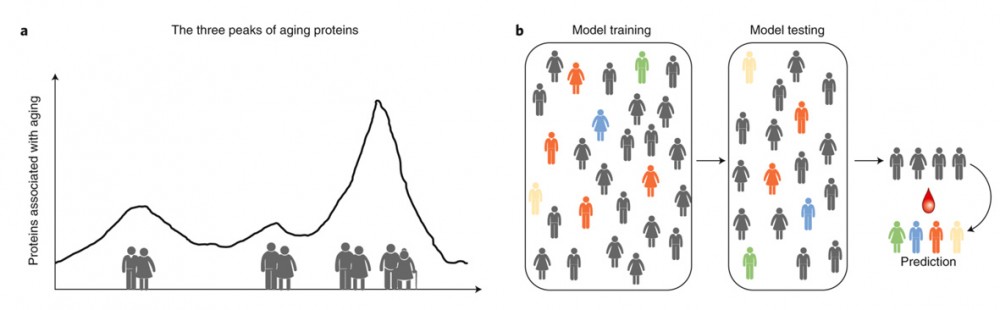

Wavelike ageing

The desire to understand the aging mechanism in humans and thereby extend lifespan or control chronic diseases has existed in all civilizations for thousands of years. Factors such as eating and drinking habits, exercise, meditation and lifestyle play a significant role in slowing down the ageing process. It is known that ageing is accompanied by changes in biochemical processes in the body. Changes at the molecular level in the blood can now be observed in detail using modern analytical techniques.

Scientists from Stanford, Saarbrücken, Bologna, Bronx and Novgorod have recently jointly published the results of a study involving 4263 people between the ages of 18 and 95. A total of 2925 plasma proteins were analyzed. Of these, 1379 plasma proteins changed with age. In addition, 895 of the 1379 age-dependent proteins showed a gender dependency. Gene expression and protein folding change over the years. However, the changes in the human plasma proteome do not occur linearly with age, but in waves. The peaks of this "ageing wave" are in the 34th, 60th and 78th year of life. Based on the data sets, a model was developed that allows a very precise statement to be made about a person's age. The identification of unexpected protein signatures and pathways through this study will play an important role in the development of therapies for age-related diseases.

Nat. Med. 2019 25, pp. 1843-1850; doi: 10.1038/s41591-019-0673-2. Epub 2019 Dec 5.

Exera® precision wire components

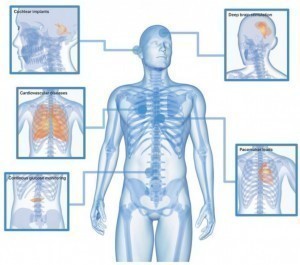

Precision wire components: Use in the human bodyFoundedin 1862,theSwedish Sandvik Group offers customized configurations for medical devices under the brand name Exera®. The wire-based components perform tasks in the human body such as transmission, perception or stimulation. Sandvik has the know-how of more than 200 alloys for the development and manufacture of Exera® products. Typical applications include biosensing, neurostimulation, implants for the middle ear and cochlea, vascular therapy, continuous glucose monitoring, conduction systems for bone and deep brain stimulation, tremor control, catheters and guidewires.

The most important alloys for the manufacture of Exera® products are stainless steel, carbon steel, platinum metals, Co-Cr-Mo alloys, sensor alloys (Konstantan®, copper) and Kanthal resistance alloys. The wires have a diameter of 0.01 to 1.0 mm and are available in lengths from 5 mm to 1800 mm. Surface treatments include electroplating, electropolishing, anodizing and coating of polymers or PTFE. Hard gold, soft gold, nickel and silver are the metals most commonly used for surface modification by electroplating.

Exera® wires

https://www.materials.sandvik/en-in/products/trademarks/exera/

Slag and concrete

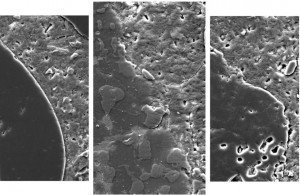

Microscopic images of concrete with "spent" slag (center) and conventional aggregates (left); raw slag (right)Significant quantities of slag are produced as a by-product in the production of steel. The slag is now used in road construction and the building industry. Slag is also used in the production of fertilizers containing calcium silicate. Slag is also a raw material in the production of mineral wool. Wastewater contains significant amounts of phosphate and must be made low in phosphate because these phosphates lead to excessive growth of aquatic flora. Some detergents still contain phosphates to soften water and bind dirt particles.

Scientists at RMIT University in Melbourne, Australia have been researching to develop new uses for slag that can no longer absorb phosphates and other contaminants in wastewater treatment plants. Dr. Pramanik and his team have found that the adsorbed impurities have a positive effect on the slag and enrich its properties as a concrete aggregate. When making concrete with "spent" slag instead of regular slag, the concrete strength increases by 8%. Spent slag was much more effective than other traditional aggregates, both after one week and after four weeks of curing. The bond between the spent slag and the concrete was stronger thanks to the absorbed impurities.

Laser texturing

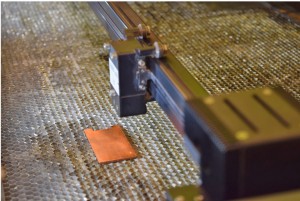

At Purdue University in the USA, scientists have topographically and chemically modified the surface of copper using laser texturing (LT-Cu). Nanoscale shapes were formed, giving the surface a higher antibacterial effect. The laser treatment created mesoporous structures with a higher concentration of oxides (Cu2Oand CuO).

The oxides contribute to a stable, superhydrophilic copper surface. In various pathogenic bacteria, it was observed that the cell membrane on the LT-Cu surface was damaged much faster - in minutes instead of hours. The biocompatibility of LT-Cu with mammalian fibroblasts was also tested. According to the authors, the hydrophilic property of laser texturing can be used for other applications, e.g. implants. Whether laser texturing can also contribute to the development of surfaces that function as virustatics is still under investigation.

Adv. Mater. Interf. 2020, 7, https://doi.org/10.1002/admi.201901890

Euro VI-compliant fuels in India

The Euro VI emissions standard has been in force in India since April 2020. Euro VI-compliant petrol and diesel are now being sold at around 69,000 filling stations. During the transition, the price was kept constant thanks to the current low oil prices. In order to keep the concentration of sulphur below 10 ppm, around 4.4 billion euros have been invested in modernizing the refineries. In 2016, the Supreme Court of India set April 2021 as the deadline for the nationwide introduction.

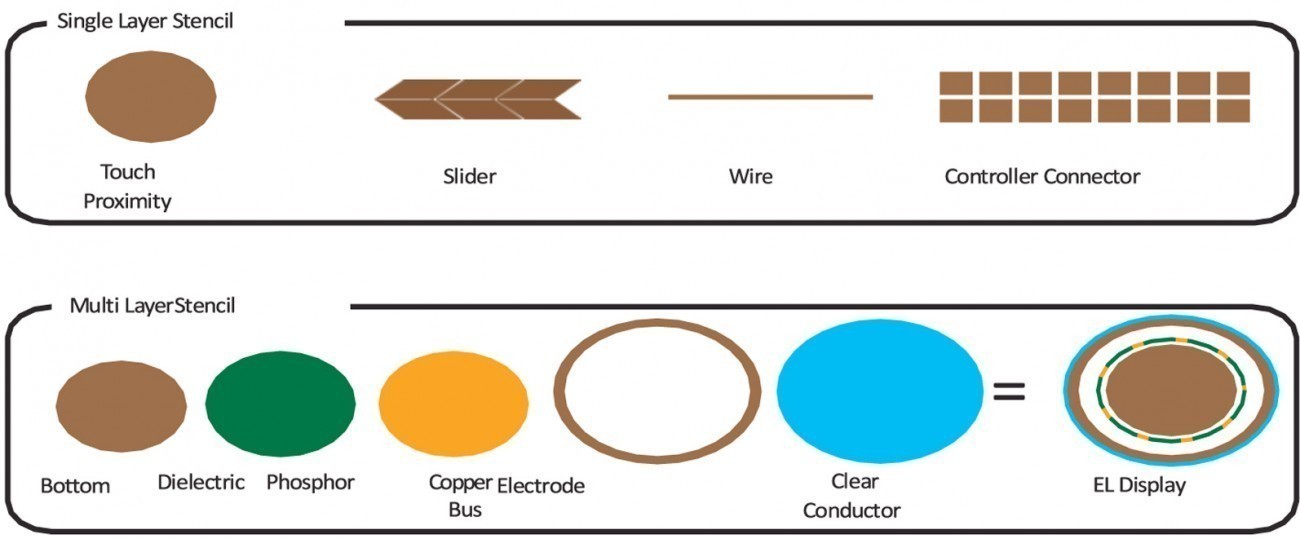

Sprayable user interfaces

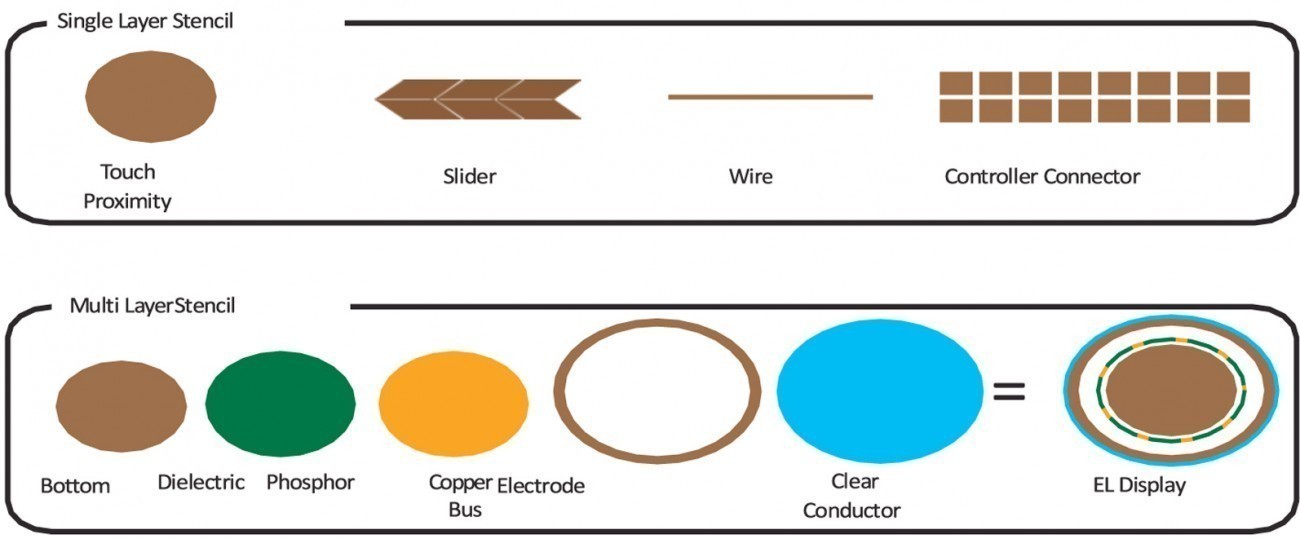

HardwareAgroup of researchers from MIT in the USA and the Universities of Bristol and Bath in the UK have developed something fascinating: sprayable user interfaces. The interface consists of five layers - copper, dielectric, phosphor, copper electrode bus and a clear conductive ink layer. The interface is active on rough and curved surfaces as well as wet outdoor surfaces.

Current techniques, including 3D printing, screen printing and inkjet printing, have many limitations that are no longer present with spray technology. Surfaces of any size, regardless of geometry, can be activated using the new technique.

Input and output elements

Input and output elements

Tong Yang Industry Taiwan

Automatic chrome plating line at Tong YangTheTong Yang Group,founded in 1952, made its lowest profits in 20 quarters last year. Tong Yang specializes in plastic and metal sheeting technology. Surface treatments include electrostatic painting and plastic electroplating.

Tong Yang is an important supplier for both OEMs and the after-sales market. More than 9000 people work in the 25 factories, which are mainly located in Taiwan and China, but also in Italy and the USA.

http://www.tyg.com.tw/en/

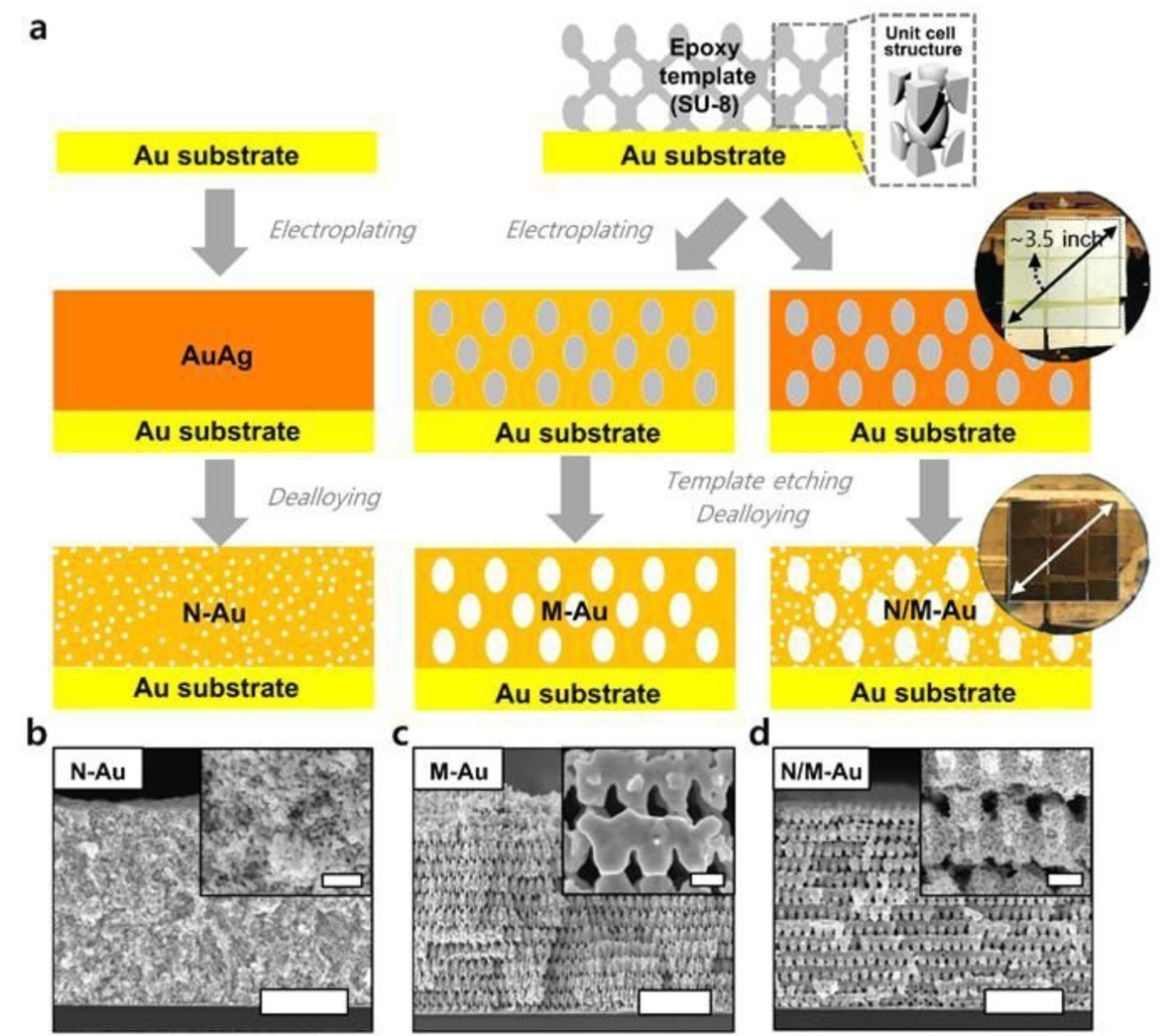

ElectrolyticCO2 reduction with gold catalysts

The electrochemical reduction ofCO2 into CO is catalyzed by gold and is accompanied by the parallel reaction of hydrogen formation. It is a challenge to develop selective catalysts that favor the reduction ofCO2. Nanoporous gold catalysts are effective, but the nanostructures are often unintentionally masked by the CO gas bubbles. The mass transport ofCO2 was prevented and the result was low conversions.

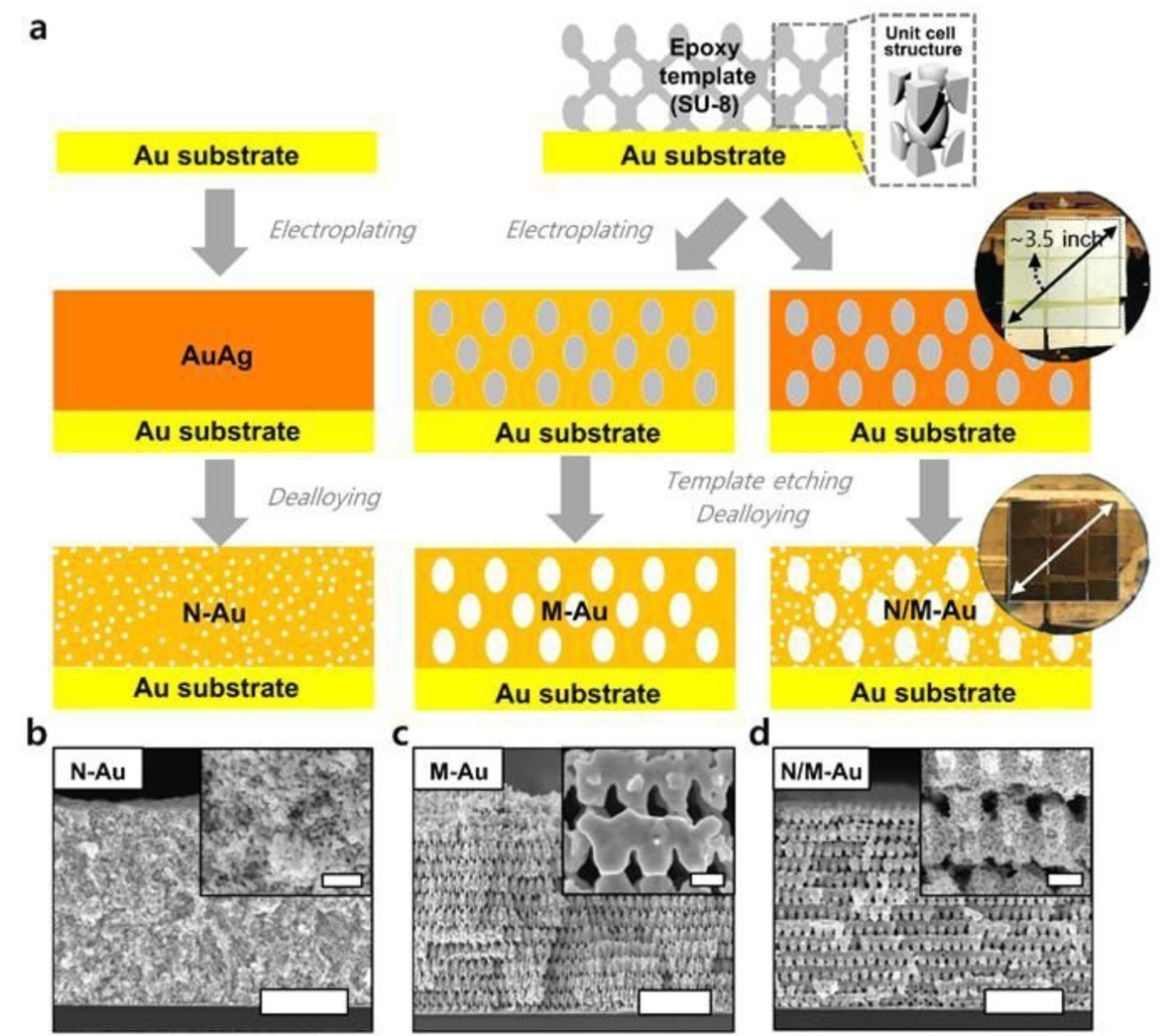

Scientists at the Korea Advanced Institute of Science and Technology KAIST have developed hierarchical nanoporous 3D gold structures with two different sizes of macropores and nanopores, where electroplating plays an important role. In addition, the proximity field nanopatterning technique was used.

Production steps for Au nanostructures using proximity field nanopatterning and gold plating. N = nanoporous; M = macroporous; N/M = hierarchical nanoporous 3D gold structures

Production steps for Au nanostructures using proximity field nanopatterning and gold plating. N = nanoporous; M = macroporous; N/M = hierarchical nanoporous 3D gold structures

The nanostructures consisted of cross-linked, macroporous channels of 200 to 300 nm width and 10 nm nanopores. Mass transfer was relatively unhindered and the number of active centers for catalysis was high and stable. Compared to previous gold electrodes, the electrode developed by Oh, Jeon and coworkers has a high CO selectivity of 85.8%. The mass activity was almost four times greater than with dealloyed, nanoporous gold electrodes. The reduction of

CO2 into CO is very relevant from an industrial point of view.

Alternatives to the use of chromium trioxide - BAUA report

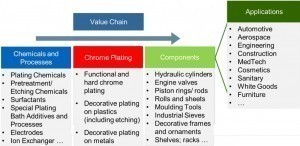

Value chain of the chrome plating industryTheFederal Institute for Occupational Safety and Health recently published a 104-page report in English on the technically and economically feasible alternatives to chromium(III) oxide in chrome plating processes.

The keywords of the excellent report are alternative testing, chromium(III) oxide, decorative chrome plating, hard chrome plating, REACH, substitution and SVHC.

https://www.baua.de/EN/Service/Publications/Report/Gd101.html; doi:10.21934/baua:report20200331

Address of the author

Dr. Nagaraj N. Rao, RRR House, RRR Labs Pvt. Ltd, Plot 80, Sector 23, Navi Mumbai - 400 705 India; Fax + 91 22 2783 4814, E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Precision wire components: Use in the human bodyFoundedin 1862,theSwedish Sandvik Group offers customized configurations for medical devices under the brand name Exera®. The wire-based components perform tasks in the human body such as transmission, perception or stimulation. Sandvik has the know-how of more than 200 alloys for the development and manufacture of Exera® products. Typical applications include biosensing, neurostimulation, implants for the middle ear and cochlea, vascular therapy, continuous glucose monitoring, conduction systems for bone and deep brain stimulation, tremor control, catheters and guidewires.

Precision wire components: Use in the human bodyFoundedin 1862,theSwedish Sandvik Group offers customized configurations for medical devices under the brand name Exera®. The wire-based components perform tasks in the human body such as transmission, perception or stimulation. Sandvik has the know-how of more than 200 alloys for the development and manufacture of Exera® products. Typical applications include biosensing, neurostimulation, implants for the middle ear and cochlea, vascular therapy, continuous glucose monitoring, conduction systems for bone and deep brain stimulation, tremor control, catheters and guidewires. Microscopic images of concrete with "spent" slag (center) and conventional aggregates (left); raw slag (right)Significant quantities of slag are produced as a by-product in the production of steel. The slag is now used in road construction and the building industry. Slag is also used in the production of fertilizers containing calcium silicate. Slag is also a raw material in the production of mineral wool. Wastewater contains significant amounts of phosphate and must be made low in phosphate because these phosphates lead to excessive growth of aquatic flora. Some detergents still contain phosphates to soften water and bind dirt particles.

Microscopic images of concrete with "spent" slag (center) and conventional aggregates (left); raw slag (right)Significant quantities of slag are produced as a by-product in the production of steel. The slag is now used in road construction and the building industry. Slag is also used in the production of fertilizers containing calcium silicate. Slag is also a raw material in the production of mineral wool. Wastewater contains significant amounts of phosphate and must be made low in phosphate because these phosphates lead to excessive growth of aquatic flora. Some detergents still contain phosphates to soften water and bind dirt particles. At Purdue University in the USA, scientists have topographically and chemically modified the surface of copper using laser texturing (LT-Cu). Nanoscale shapes were formed, giving the surface a higher antibacterial effect. The laser treatment created mesoporous structures with a higher concentration of oxides (Cu2Oand CuO).

At Purdue University in the USA, scientists have topographically and chemically modified the surface of copper using laser texturing (LT-Cu). Nanoscale shapes were formed, giving the surface a higher antibacterial effect. The laser treatment created mesoporous structures with a higher concentration of oxides (Cu2Oand CuO). HardwareAgroup of researchers from MIT in the USA and the Universities of Bristol and Bath in the UK have developed something fascinating: sprayable user interfaces. The interface consists of five layers - copper, dielectric, phosphor, copper electrode bus and a clear conductive ink layer. The interface is active on rough and curved surfaces as well as wet outdoor surfaces.

HardwareAgroup of researchers from MIT in the USA and the Universities of Bristol and Bath in the UK have developed something fascinating: sprayable user interfaces. The interface consists of five layers - copper, dielectric, phosphor, copper electrode bus and a clear conductive ink layer. The interface is active on rough and curved surfaces as well as wet outdoor surfaces. Input and output elements

Input and output elements Automatic chrome plating line at Tong YangTheTong Yang Group,founded in 1952, made its lowest profits in 20 quarters last year. Tong Yang specializes in plastic and metal sheeting technology. Surface treatments include electrostatic painting and plastic electroplating.

Automatic chrome plating line at Tong YangTheTong Yang Group,founded in 1952, made its lowest profits in 20 quarters last year. Tong Yang specializes in plastic and metal sheeting technology. Surface treatments include electrostatic painting and plastic electroplating. Production steps for Au nanostructures using proximity field nanopatterning and gold plating. N = nanoporous; M = macroporous; N/M = hierarchical nanoporous 3D gold structures

Production steps for Au nanostructures using proximity field nanopatterning and gold plating. N = nanoporous; M = macroporous; N/M = hierarchical nanoporous 3D gold structures Value chain of the chrome plating industryTheFederal Institute for Occupational Safety and Health recently published a 104-page report in English on the technically and economically feasible alternatives to chromium(III) oxide in chrome plating processes.

Value chain of the chrome plating industryTheFederal Institute for Occupational Safety and Health recently published a 104-page report in English on the technically and economically feasible alternatives to chromium(III) oxide in chrome plating processes.