What would it have been like if ...?

In our daily professional lives, we meet people who work in completely different professions than electroplating. One would assume that they have perhaps heard little about electroplating or have had nothing to do with it in their lives. It is therefore always gratifying to meet a person who has been involved with electroplating at some point in their career, whether as a student, a temp, an apprentice, an electroplater, an entrepreneur or in research and development, before that person was attracted to other subjects. It would also be gratifying if these people looked back fondly and with pleasure on their electroplating days, perhaps because they learned a lot and something stayed with them.

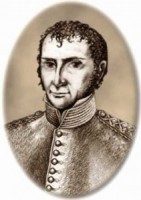

Johann Wilhelm Ritter

J. W. Ritter personally knew the intellectual elite of Germany at the time(1776-1810) from Samitz began his career as an apprentice in a pharmacy, studied medicine and was very interested in chemistry. He is said to have discovered electroplating in Jena in 1800. He studied the electrolysis of water and developed the dry battery. He discovered the UV range of the electromagnetic spectrum. In the last years of his short life, he worked on electrophysiology.

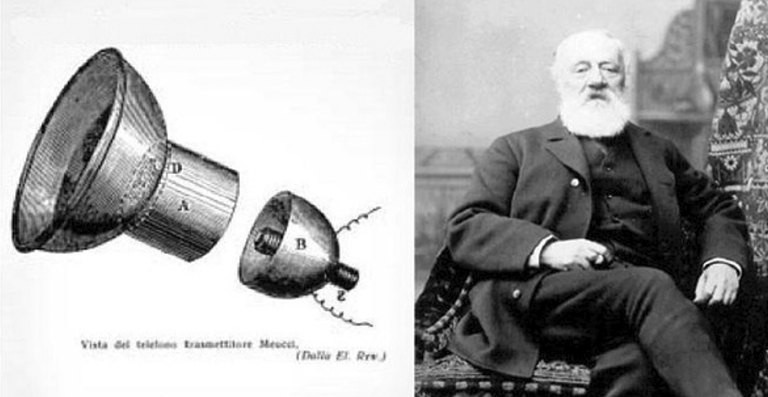

J. W. Ritter personally knew the intellectual elite of Germany at the time(1776-1810) from Samitz began his career as an apprentice in a pharmacy, studied medicine and was very interested in chemistry. He is said to have discovered electroplating in Jena in 1800. He studied the electrolysis of water and developed the dry battery. He discovered the UV range of the electromagnetic spectrum. In the last years of his short life, he worked on electrophysiology.Antonio Meucci

The life of Antonio Meucci (1808-1889) spanned Italy, Cuba and the USA. He studied mechanical engineering and technical chemistry and was politically active in Italy. At the age of 27, he emigrated with his wife to Cuba, then still a Spanish colony, where he developed a water purification system for the city of Havana. He was awarded a contract to supply electroplating-related products and materials for the army and founded an electroplating company.

Sewage pioneer: Antonio Meucci

Sewage pioneer: Antonio Meucci

Thomas Edison

Alexander Parkes

Edward Weston

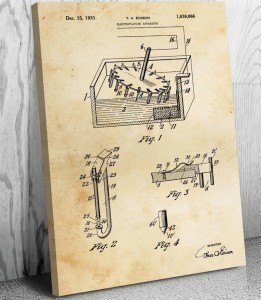

Weston-Cell(1850-1936) studied medicine but was interested in chemistry. Shortly after emigrating to America, he got a job in the electroplating industry. Among his many achievements, the development of the electrochemical cell, known as the Weston Cell, is of great importance for electroplating technology.

Weston-Cell(1850-1936) studied medicine but was interested in chemistry. Shortly after emigrating to America, he got a job in the electroplating industry. Among his many achievements, the development of the electrochemical cell, known as the Weston Cell, is of great importance for electroplating technology.Albert Einstein

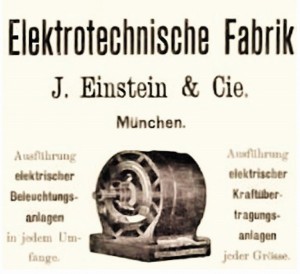

(1879-1955) himself had obviously never had anything to do with electroplating, but his father and uncle owned a small electroplating company in Munich before it went bankrupt.

Charles Kettering

Louis LaMoore

Richard Feynman

June Schwarcz

The artist June Schwarcz (née Morris, 1918-2015) learned the enameling technique at the age of 36. She then combined enameling with electroplating, often sandblasting, to create a wide range of artistic works over the next sixty years, the last of which was completed a week before her death. She had already learned how to etch metals as a student in a school project. She regarded her works - primarily vessels and panels - as non-functional sculpture.

The artist June Schwarcz (née Morris, 1918-2015) learned the enameling technique at the age of 36. She then combined enameling with electroplating, often sandblasting, to create a wide range of artistic works over the next sixty years, the last of which was completed a week before her death. She had already learned how to etch metals as a student in a school project. She regarded her works - primarily vessels and panels - as non-functional sculpture.Schwarcz's innovative ideas were transformed into works of art using copper-plated copper foils and grids. Many aspects of her life inspired her to create works of art. According to unconfirmed reports, some copper plating was done in the bathtub.

https://www.pfonline.com/articles/celebrities-who-once-worked-in-electroplating

Schwarcz's works have been immortalized in many well-known museums around the world, including the Smithsonian

Schwarcz's works have been immortalized in many well-known museums around the world, including the Smithsonian

DuPont Global Photovoltaic Reliability Report 2020

The annual Global Photovoltaic Reliability Report 2020 has recently been published by DuPont. Supported by a sophisticated field inspection system and analysis program, DuPont monitors the degradation of materials in photovoltaic installations worldwide and their impact on PV module performance. Variables such as components, material, mounting, service time and climate are analyzed.

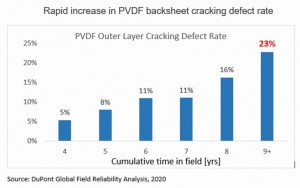

The annual Global Photovoltaic Reliability Report 2020 has recently been published by DuPont. Supported by a sophisticated field inspection system and analysis program, DuPont monitors the degradation of materials in photovoltaic installations worldwide and their impact on PV module performance. Variables such as components, material, mounting, service time and climate are analyzed. In installations in China, Europe, India and North America, cracking in the outer PVDF layer was found to have increased from 5% to 23% between year 4 and year 9. This exposed the core layer to the natural elements. This in turn caused tripping of the converter and ground faults in some cases.

In installations in China, Europe, India and North America, cracking in the outer PVDF layer was found to have increased from 5% to 23% between year 4 and year 9. This exposed the core layer to the natural elements. This in turn caused tripping of the converter and ground faults in some cases.Self-limiting electrospray coating and additive manufacturing

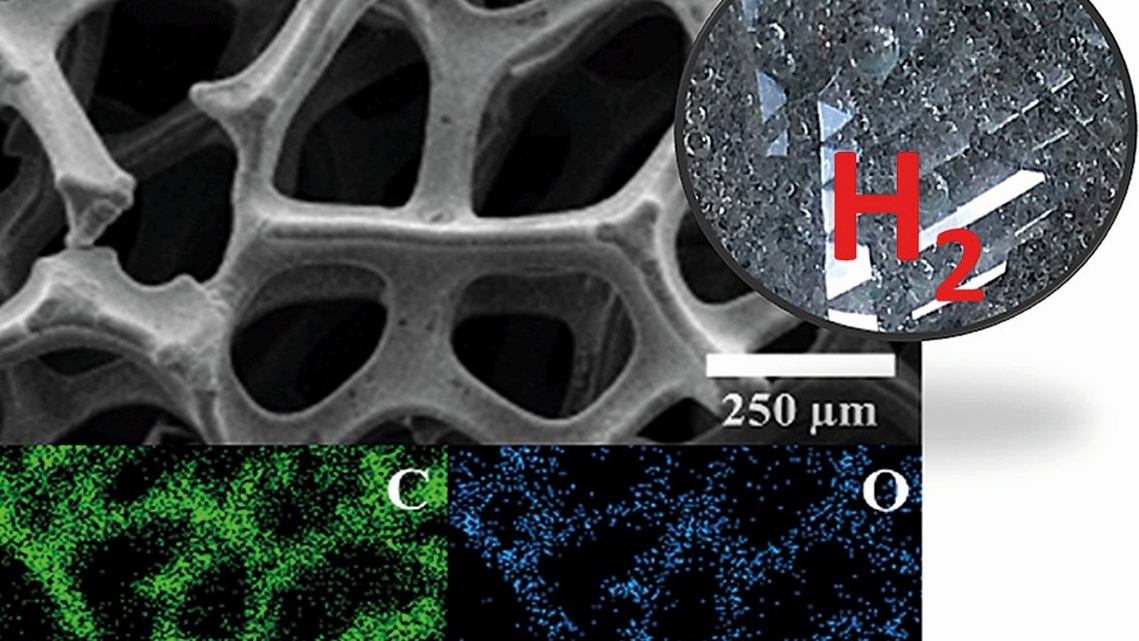

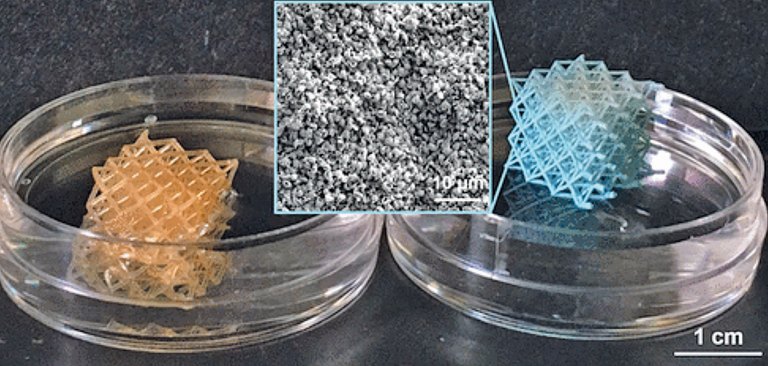

The electrospray ionization (ESI) technique is of great importance in the analysis of polymers using mass spectrometry. In this technique, ions are generated by electrospray. A liquid is subjected to a high voltage to form an aerosol. In the meantime, ESI has also become a coating technique. Electrospray deposition (ESD) is a nanofabrication process in which natural and synthetic polymers and composite solutions form charged micro-droplets as they flow and are sprayed. After evaporation of the solvent, the solids form the layer.

At Rutgers University in New York, the topic of self-limiting ESD is being researched. Such sprays are able to coat complex 3D objects in a self-limiting manner without changing the position of the spray needle or the orientation of the object. Objects that are produced using additive manufacturing can be ideally coated with the self-limiting electrospray coating. Coating thicknesses of up to 50 mm on conductive objects have been demonstrated. Hydrogel structures formed by additive manufacturing could also be coated using this technique to generate hydrophobic surfaces. The coatings were robust and superhydrophobicity was demonstrated throughout the structure.

ACS Appl. Mater. Interfaces 2020, 12, pp. 20901-20911

Direct Alloy Printing

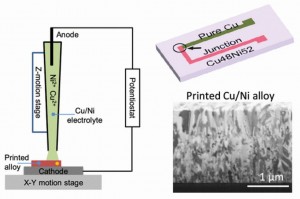

Special applications need special surfaces. Functional devices, for example thermocouples, thermopiles and heat flux sensors, often contain components that carry a functional coating. The alloy coating of an electrolyte is a challenge. Scientists at the University of Dallas in Texas have for the first time used a single electrolyte to coat a single-phase solid solution consisting of a nanocrystalline copper-nickel alloy.

Special applications need special surfaces. Functional devices, for example thermocouples, thermopiles and heat flux sensors, often contain components that carry a functional coating. The alloy coating of an electrolyte is a challenge. Scientists at the University of Dallas in Texas have for the first time used a single electrolyte to coat a single-phase solid solution consisting of a nanocrystalline copper-nickel alloy.V-Mn conversion coating in front of electroless nickel-phosphorus

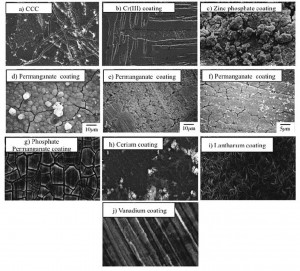

Recently, vanadium-based conversion coatings on Al-Mg alloys have been intensively tested for their corrosion protection. Scientists in Taiwan have carried out this investigation using an LZ91Mg alloy as a substrate.

Recently, vanadium-based conversion coatings on Al-Mg alloys have been intensively tested for their corrosion protection. Scientists in Taiwan have carried out this investigation using an LZ91Mg alloy as a substrate.Graphene oxide coating on chrome layers

Surf. Coat. Technol. 2020, 391, 125595; https://doi.org/10.1016/j.surfcoat.2020.125595