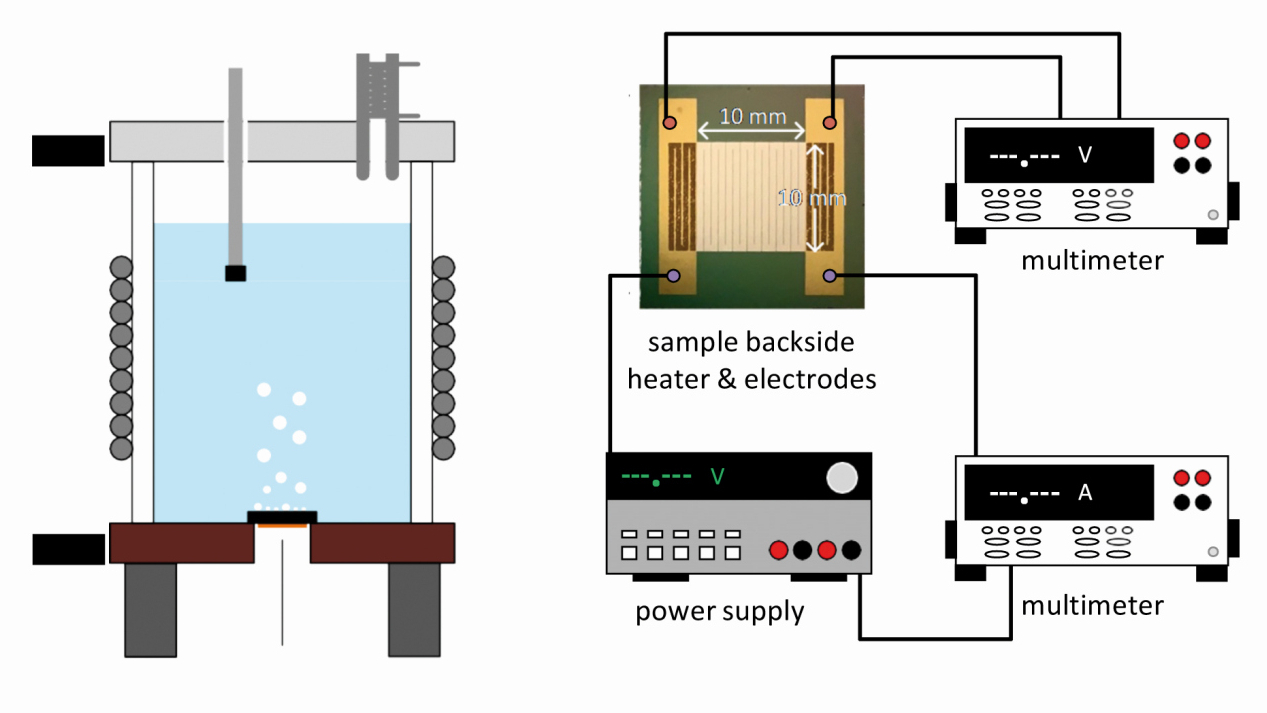

Researchers at MIT in the US say they have discovered a more energy-efficient method of heating water on a laboratory scale. They created three different surface modifications, all at different scales, to achieve this. These modifications allow for a more efficient method of boiling water.

The modifications do not detract from the possibilities this technique could offer. According to the paper, the researchers focused primarily on two key parameters that help describe the boiling process: The heat transfer coefficient (HTC) and the critical heat flux (CHF). To develop this more efficient method of boiling water, the researchers first had to figure out how to better balance HTC and CHF, as normally improving one of the two parameters worsens the other.

In general, many bubbles on the boiling surface mean that boiling is very efficient (Fig. 1).

However, if there are too many bubbles on the surface, they can clump together and form a steam-like film over the boiling water. If this more efficient way of boiling water becomes usable on an industrial scale, it would help the electroplating industry, among others, to save energy.

Adv. Mater. 2022, 34, 32, https://doi.org/10.1002/adma.202200899

Aqueous high-energy batteries and hybrid supercapacitors

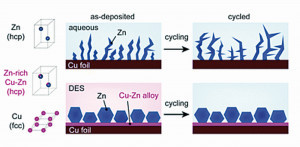

Fig. 2: Zinc metal anode fabricationAqueousZn-ion batteries (AZIBs) offer relatively good safety for large-scale energy storage applications. However, the development of highly reversible zinc metal anodes with limited capacity is a prerequisite for realizing the performance characteristics of AZIBs comparable to those of commercial batteries. Korean scientists have addressed this issue by identifying the growth mechanism of densely packed micrometer-sized Zn particles on Cu foil to construct a stable anode with a suitable Zn loading for AZIBs. Deep eutectic solvents were found to induce an unusual Cu-Zn alloying reaction that produces a zincophilic and Zn-rich alloy interlayer isotypic to the pure Zn phase. This alloy layer in turn forms compact Zn deposits whose structure can withstand continuous cycling in an aqueous electrolyte, effectively preventing AZIB corrosion and swelling.

Fig. 2: Zinc metal anode fabricationAqueousZn-ion batteries (AZIBs) offer relatively good safety for large-scale energy storage applications. However, the development of highly reversible zinc metal anodes with limited capacity is a prerequisite for realizing the performance characteristics of AZIBs comparable to those of commercial batteries. Korean scientists have addressed this issue by identifying the growth mechanism of densely packed micrometer-sized Zn particles on Cu foil to construct a stable anode with a suitable Zn loading for AZIBs. Deep eutectic solvents were found to induce an unusual Cu-Zn alloying reaction that produces a zincophilic and Zn-rich alloy interlayer isotypic to the pure Zn phase. This alloy layer in turn forms compact Zn deposits whose structure can withstand continuous cycling in an aqueous electrolyte, effectively preventing AZIB corrosion and swelling.

Due to the high reversibility of the Zn anode with a Cu-Zn alloy interlayer, the AZIB, which uses more than 25% Zn from the compact anode, can achieve over 7000 cycles. This makes it possible to design AZIBs with competitive energy densities. With lithium-ion batteries (LIBs), which are used as energy storage systems (ESS), the risk of fire has recently proved to be a major disadvantage in many places. In addition to water as an electrolyte, zinc is a much cheaper and readily available raw material. The zinc metal anodes with high energy density and long service life are produced by a simple electroplating process using inexpensive and environmentally friendly solutions (Fig. 2).

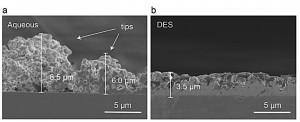

Fig. 3: SEM cross-sectional images of the Zn deposits (2 mAh cm-2) after electrodeposition on Cu foil (a) using an aqueous 2 M ZnSO4 electrolyte at 2 mA cm-2 and (b) using 0.1 M ZnSO4 in 12CU at 0.1 mA cm-2 To prepare the compact zinc anodes, the team used a well-known deep eutectic solution (DES) that can be easily synthesized at room temperature. This DES solution consists of choline chloride and urea mixed in a 1:2 molar ratio; the mixture forms a liquid complex with a melting point of 12 °C. The researchers confirmed that a zincophilic copper-zinc alloy layer spontaneously forms between the zinc and copper current collectors in the DES, enabling the growth of high-density zinc particles. With this discovery, the researchers succeeded in developing an electroplating process that enables dense and uniform growth of zinc metals in the cost-effective and environmentally friendly DES solution (Fig. 3).

Fig. 3: SEM cross-sectional images of the Zn deposits (2 mAh cm-2) after electrodeposition on Cu foil (a) using an aqueous 2 M ZnSO4 electrolyte at 2 mA cm-2 and (b) using 0.1 M ZnSO4 in 12CU at 0.1 mA cm-2 To prepare the compact zinc anodes, the team used a well-known deep eutectic solution (DES) that can be easily synthesized at room temperature. This DES solution consists of choline chloride and urea mixed in a 1:2 molar ratio; the mixture forms a liquid complex with a melting point of 12 °C. The researchers confirmed that a zincophilic copper-zinc alloy layer spontaneously forms between the zinc and copper current collectors in the DES, enabling the growth of high-density zinc particles. With this discovery, the researchers succeeded in developing an electroplating process that enables dense and uniform growth of zinc metals in the cost-effective and environmentally friendly DES solution (Fig. 3).

The application experiments indicate that the corrosion reaction can be effectively suppressed and the capacity is maintained at more than 70 % after more than 7000 repeated charging and discharging processes.

Energy Environ Sci 2022,7, DOI: https://doi.org/10.1039/D2EE00617K

Chip production in India

Polymatech Electronics, a semiconductor manufacturer based in Tamil Nadu that used to belong to Fuji Rubber, will build facilities capable of producing up to 2 billion chips per year by the beginning of next year, according to media reports. The company will invest 1 billion US dollars for this and use its products in various industries through integration in both directions. The current annual production capacity is 250 million chips. Backward integration will involve the cutting of ingots and the growing of crystals. The production of wafers is then planned. The market includes integrated chips, RAMs, ROMs, EEPROMs as well as ultraviolet and studio lamps. Semiconductors, which are required for devices such as laptops, cell phones and televisions, are also another vertical area. The company has already applied for several patents and is therefore in a strong position in the industry. Talks are currently underway to acquire a company in Europe to meet the demand in this region, which is mainly in the aviation industry.

There is also news from the company Sahasra Semiconductors, which plans to assemble, test and package memory chips in India (ATMP). The company plans to sell its own chips by December. This could be the first ATMP plant for memory chips in India.

Mobility with H2

While India is looking to develop a supply chain for green hydrogen and green ammonia, the US company Triton Electric Vehicle has announced plans to produce and launch hydrogen-powered two- and three-wheelers in India - the first Indian-made H2-powered vehicles. Triton has set up a research and development center in Anand, Gujarat, for the development of two- and three-wheelers.

Easykit

Fig. 4: Easykit turns any bike into an e-bike in just a few stepsFig.4 shows a universal DIY front wheel conversion kit with a 250 W front wheel motor, a 209 Wh Li-ion battery, a compact charger, an easy-to-install pedal assist sensor, a control unit, a throttle, a wiring harness and e-brakes. Unlike conventional e-bikes, the battery box is not attached to the frame but sits on top of the handlebars, making it suitable for any bike model. Any bike can be converted into an electric bike in a few steps by replacing the front tire with the one included in the kit, attaching the upper assembly consisting of the battery and controller, attaching the pedal assist sensor to the crankset and attaching the e-brakes and throttle. Most users in India already have a bike at home and any bike can be converted into an e-bike in about 20 minutes.

Fig. 4: Easykit turns any bike into an e-bike in just a few stepsFig.4 shows a universal DIY front wheel conversion kit with a 250 W front wheel motor, a 209 Wh Li-ion battery, a compact charger, an easy-to-install pedal assist sensor, a control unit, a throttle, a wiring harness and e-brakes. Unlike conventional e-bikes, the battery box is not attached to the frame but sits on top of the handlebars, making it suitable for any bike model. Any bike can be converted into an electric bike in a few steps by replacing the front tire with the one included in the kit, attaching the upper assembly consisting of the battery and controller, attaching the pedal assist sensor to the crankset and attaching the e-brakes and throttle. Most users in India already have a bike at home and any bike can be converted into an e-bike in about 20 minutes.

There is also news from the Indian smartphone industry: Apple is expanding its supply chain in Asia and as a result Foxconn is reportedly expanding production at its Chennai plant and will manufacture the iPhone 14 here.