With more than 400 years of experience in metallurgy, Feinhütte Halsbrücke is one of the oldest smelters in Europe and Germany's only tin and lead smelter. The specialists for soft solders and alloys supply customers according to standard and individual specifications.

Anyone who thinks that the policy of tall chimneys is a modern invention is mistaken. The Halsbrück "Hohe Esse", the tallest industrial chimney in the world at the time at 140 meters high, was put into operation back in 1889.

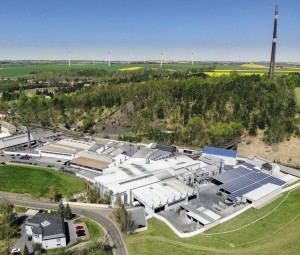

Bird's-eye view: even before the Thirty Years' War, a smelter with four furnaces stood on this site - "officially approved" by the Elector himself "It's Monday morning. The workers at Feinhütte Halsbrücke GmbH stream onto the site of one of the oldest company locations in Europe for their first shift of the day. In the shadow of the "Hohe Esse", they can literally feel the more than 400 years of company history that have shaped the regionally rooted company, which is also known far beyond its borders. Numerous tsars and kings have stopped by here over the years, and world-class inventors have conducted research here. Alexander von Humboldt also paid a visit.

Bird's-eye view: even before the Thirty Years' War, a smelter with four furnaces stood on this site - "officially approved" by the Elector himself "It's Monday morning. The workers at Feinhütte Halsbrücke GmbH stream onto the site of one of the oldest company locations in Europe for their first shift of the day. In the shadow of the "Hohe Esse", they can literally feel the more than 400 years of company history that have shaped the regionally rooted company, which is also known far beyond its borders. Numerous tsars and kings have stopped by here over the years, and world-class inventors have conducted research here. Alexander von Humboldt also paid a visit.

While the workers put on their PPE, their personal protective equipment, for example the full-face blower helmet, at the start of their shift, long-serving employees sometimes think back to times gone by. Until reunification, several thousand iron and steel workers were employed in the Erzgebirge mining region. After reunification, the current managing director Lothar Patzig succeeded in privatizing Feinhütte with great effort and against the resistance of the Treuhand. The new owner invested tens of millions in order to continuously optimize all processes. Investments in the company are still ongoing today. The excellent reputation that Feinhütte Halsbrücke enjoys is not the only proof that this pays off. Germany's only remaining tin smelter now produces practically all tin and lead alloys in almost limitless varieties and formats for customers in all branches of industry and commerce. This also includes a wide range of anodes.

Recycling old materials protects the environment and conserves raw material resources

Furthermore, the responsible recycling of metals has been a top priority at the Feinhütte Halsbrücke site for centuries. The well-trained workers are experts when it comes to the proper and environmentally friendly disposal of old materials. Especially in times of increasing demand for raw materials, scarce resources and ever stricter environmental regulations, extensive expertise is required when it comes to taking back old solders and other process waste. After all, sustainable recycling cycles can only function smoothly if the take-back and environmentally friendly treatment of these secondary materials are inextricably linked and the return to the materials cycle takes place in the country of origin wherever possible.

The procurement of secondary materials is a complex yet extremely important process. Several employees demonstrate their expertise here every day. Not only do they have extensive knowledge of the different materials, their properties and their recycling options, but they are also in close contact with processing companies and major recyclables dealers. The employees also maintain a Europe-wide supplier network in order to counteract supply bottlenecks. The continuously trained specialists are familiar with the relevant legal regulations and know, for example, which requirements arise from the Recycling Management Act with regard to secondary materials and their transportation. They therefore not only advise customers and suppliers, but also take care of the formalities relating to notifiable materials, transport permits and disposal documents. They also document the evidence as part of the voluntary take-back in accordance with Section 26 KrWG - digitally and legally compliant.

Electrolysis: The electrolysis technology newly developed by Feinhütte Halsbrücke enables a high degree of hydrometallurgical vertical integration

Electrolysis: The electrolysis technology newly developed by Feinhütte Halsbrücke enables a high degree of hydrometallurgical vertical integration

Rough work: Wheel loaders and excavators are used to sort the materials according to their properties. The large warehouse ensures process reliability At the same time, the range of input materials that can be fed back into the raw material cycle using almost residue-free full recycling processes is constantly growing. For example, the experts at Feinhütte Halsbrücke can carefully reprocess and reuse materials containing lead, tin and antimony, even if they are contaminated with copper. However, specialist knowledge is essential if almost all metallic, oxidic and sulphide materials are to be reused and new products created from metallic residues. 70 workers in 4 shifts ensure that the furnaces and boilers are constantly working at full capacity. Some of them sort the metallic residues delivered to the incoming goods department. They differentiate between old anodes, metallic slurries and oxidic materials such as sludge or dross. Using forklifts, cranes, wheel loaders and excavators, the employees sort the materials according to their properties. The large warehouse ensures process reliability. After thorough sampling, the employees place the materials in the aggregates, whereby the pyrometallurgical processing is carried out using heavy equipment. Dusts, sludges, salts, slags and furnace scrap are mainly exposed to heat of more than 1000 degrees Celsius in the furnace.

Rough work: Wheel loaders and excavators are used to sort the materials according to their properties. The large warehouse ensures process reliability At the same time, the range of input materials that can be fed back into the raw material cycle using almost residue-free full recycling processes is constantly growing. For example, the experts at Feinhütte Halsbrücke can carefully reprocess and reuse materials containing lead, tin and antimony, even if they are contaminated with copper. However, specialist knowledge is essential if almost all metallic, oxidic and sulphide materials are to be reused and new products created from metallic residues. 70 workers in 4 shifts ensure that the furnaces and boilers are constantly working at full capacity. Some of them sort the metallic residues delivered to the incoming goods department. They differentiate between old anodes, metallic slurries and oxidic materials such as sludge or dross. Using forklifts, cranes, wheel loaders and excavators, the employees sort the materials according to their properties. The large warehouse ensures process reliability. After thorough sampling, the employees place the materials in the aggregates, whereby the pyrometallurgical processing is carried out using heavy equipment. Dusts, sludges, salts, slags and furnace scrap are mainly exposed to heat of more than 1000 degrees Celsius in the furnace.

The employees who monitor the reducing melting in the furnace with the addition of aggregates wear fireproof clothing and a fully protective blower helmet. The sometimes very complex processes and the operation of the specific equipment are also an exciting environment for young people in training. For example, they learn how classic anodes are produced, which casting processes are used for rod or plate anodes and everything about extruding processes for bulk anodes.

Different anode shapes for many applications in electroplating technology

Variety of anodes: Bulk, rod, spherical and plate anodes are used in electroplating. High purity is a prerequisite Because modern materials management is anything but a one-way street, the experts at Feinhütte Halsbrücke have also developed numerous processes. This enables them to achieve qualities of up to Sn 99.99 or Pb 99.99, produce high-quality products from process waste and, if required, achieve purities far above the market level. The sticks developed in Halsbrücke are characterized by a significantly reduced oxide layer in the application. The low-lead tin used, with a material analysis value of < 0.005%, is fundamental to this. This continuously tested and documented value is often even significantly lower.

Variety of anodes: Bulk, rod, spherical and plate anodes are used in electroplating. High purity is a prerequisite Because modern materials management is anything but a one-way street, the experts at Feinhütte Halsbrücke have also developed numerous processes. This enables them to achieve qualities of up to Sn 99.99 or Pb 99.99, produce high-quality products from process waste and, if required, achieve purities far above the market level. The sticks developed in Halsbrücke are characterized by a significantly reduced oxide layer in the application. The low-lead tin used, with a material analysis value of < 0.005%, is fundamental to this. This continuously tested and documented value is often even significantly lower.

The experts at Feinhütte Halsbrücke offer their customers a wide range of different anode types, specifications and packaging variants. If required, they also take on the engineering and design of new anode shapes and record all process steps both analog and digital. The material analysis of each batch is also made available to customers as part of the service.

Feinhütte Halsbrücke can look back on a long history. At the same time, the traditional, historic smelter has developed into one of the most modern and technologically leading specialists for non-ferrous metals and metal alloys. To ensure that innovations continue to drive the company's success in the future, the grandson of founder Tobias Patzig, who took over the management of Feinhütte Halsbrücke in April 2017, relies on the clever combination of drive and decisiveness of the younger generation with the experience and composure of his elders.

INFO

About Feinhütte Halsbrücke

With over 400 years of experience in metallurgy, Feinhütte Halsbrücke is one of the oldest smelters in Europe and Germany's only tin and lead smelter. The product range covers almost every common format - from ingots and blocks to bars, rods and bolts, wire and tubular solder, classic anodes and practical bulk material formats. Feinhütte Halsbrücke also offers various services, such as solder bath analysis, solder bath management, laboratory diagnostics and comprehensive full recycling of process residues.