At the SGO technical symposium in Biel at the beginning of May, the focus was on technical innovations in electroplating with a view to the scarcity of resources. The focus was on practical savings of all kinds, but also on the life cycle analysis of surface processes, digital efficiency methods and measurement technology.

In the north-west of Switzerland, on the German-French language border, lies the city of Biel/Bienne, which has a population of 55,000. This is where the Swiss Society for Surface Technology (SGO) held its Technical Conference in the Tissot Arena at the beginning of May. The Tissot Arena is named after the large Swiss watch manufacturer in nearby Le Locle. The luxury watch business characterizes the entire region, which is also home to many electroplating companies - traditional suppliers to the watch industry. Biel itself is home to the chronograph manufacturer Omega, while other exclusive manufacturers are located in a long ribbon from the Vallée des Joux (also known as the Valley of Watches) southwest of Lake Neuchâtel down to Geneva.

Lifestyle wristwatch: showcases in the arena display fine Tissot chronographs

Lifestyle wristwatch: showcases in the arena display fine Tissot chronographs

Around 200 companies for electroplating and surface technology in Switzerland

With around 200 companies, the Swiss electroplating and surface technology sector is quite small in comparison to the German sector, but nevertheless diverse. The focus of this year's event with around 50 participants was the topic of resource conservation. This involved water as well as energy and the efficient use of raw materials.

Savings in cleaning and waste water

Dr. Clément Cremmel from KKS Ultraschall AG in Steinen kicked things off. His company specializes in the surface treatment and cleaning of devices and instruments in the field of medical technology. He spoke about aqueous cleaning and the potential for saving water and energy, for example by recovering waste heat, but also by insulating baths, which, according to him, can result in energy savings of up to 17%. KKS Ultraschall continues to work on energy-efficient solutions for the aqueous cleaning of components

The next speaker was Electroplating Advisory Board member and ProWaTech Managing Director Herbert Hauser. His company, which was recently taken over by EnviroChemie, Eschenbach/Switzerland, plans and supplies water treatment plants, among other things. In view of the rise in energy costs from 18 to 40 centimes per kWh, Hauser described how costs and resources can be saved in electroplating plants. He also described tried and tested methods for making savings, such as reverse osmosis - where a 10% reduction in electricity consumption is possible over 8 years - ion exchangers, which can save up to 50% NaCl and water, and physical processes for recovery, such as electrolysis or evaporation. Using the example of a "Hot Air Dryer", he illustrated the increased energy costs and promoted the "Cold Air Dryer" as an economical alternative. Other topics included reducing the discharge of process solutions in the rinsing process and extending service life through cleaning.

Increasing sustainability with life cycle analysis

The subsequent presentation by Dr. Roman Fuchs from FME GmbH in Neuhausen am Rheinfall was canceled due to illness. This would have been about AAA-Coat, a glass-ceramic coating made of modified silicon oxide networks for substrates made of metal, glass, ceramics, cardboard/paper or special plastics.

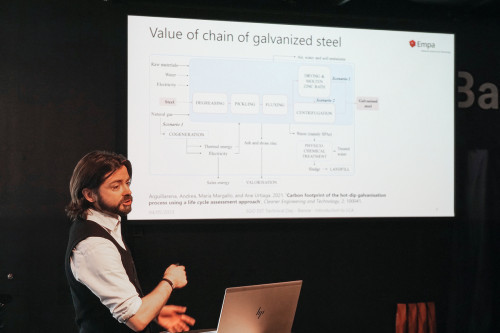

Dr. Beloin-Saint-Pierre from Empa uses life cycle analysis to determine the CO2 footprint of surface processes

Dr. Beloin-Saint-Pierre from Empa uses life cycle analysis to determine the CO2 footprint of surface processes

Due to the cancellation of the presentation, the topic of Dr. Didier Beloin-Saint-Pierre from Empa was brought forward. He spoke about the life cycle analysis (LCA method) of coating processes, including electroplating zinc, and also showed the results via projector. The method is based on the international standards ISO 14040 and 14044 for life cycle assessment. Beloin-Saint-Pierre showed how the most important starting points for sustainable development can be identified. The lively discussion that followed demonstrated the high level of interest in the topic from the Swiss electroplating and surface technology sector. SGO President Patrik Schmutz (read the interview) pointed out in the Q&A session that social aspects should also be included in the life cycle analysis in addition to toxicity, water and electricity consumption.

Simulate, visualize and simplify processes

After the lunch break and the SGO General Assembly, the event continued in the afternoon. The speaker now was Dr. Baptiste Fedi with his presentation "Towards environmentally friendly industrial production through multiphysical modeling and data science applied to surface technology". Dr. Fedi is CEO of the French consulting company Hivelix, specializing in multiphysical modelling and development of digital twins for chemical and electrochemical processes. In his presentation, Dr. Fedi showed how simulation can help to achieve ideal surface properties. Using data sciences and the hybridization of simulation models, he showed how the predictive ability of models can be improved and optimized in an industrial environment.

The second speaker in the second session of the event was Roland Ratschiller, who was already an interview partner of Galvanotechnik in May 2022 with fire protection expert Alexander Volodarski. He spoke about "Electroless nickel-phosphorus deposition - multi-component vs. single-component systems" and first outlined the principle and practice of using electroless nickel in electroplating. Multi-component systems require in-depth process knowledge, especially when it comes to dispersion coatings. In the meantime, single-component systems are gaining ground. Finally, Ratschiller presented a survey on single-component systems from the USA, where there was positive feedback. The benefits include increased employee motivation, easier procurement, simplified process management and less product stockpiling in the chemical warehouse.

Familiar atmosphere: Most of the participants came from Switzerland, but a few also came from France and Germany

Familiar atmosphere: Most of the participants came from Switzerland, but a few also came from France and Germany

The last presentations at the technical symposium initially dealt with a software solution from the Karlsruhe-based company Softec for visualizing order statuses in order to respond to customer inquiries. Speaker Arnaud Kropp, who was also in charge of his company's stand at the accompanying trade exhibition, also addressed the origin of the data in his presentation and concluded by discussing another of his company's offerings for electroplating shops in the form of augmented reality. He was followed by Ulrich Menner, Managing Director of Argenbühl-based plant engineering company V+L InfraManagement GmbH. He presented process optimizations and potential for energy savings in existing systems as well as heat recovery and economical exhaust air purification systems. The last speaker was Virgile Favre from Anton Paar Tritec SA, a measuring device manufacturer from Corcelles, not far from Biel on Lake Neuchâtel, which specializes in electroplating measuring devices such as viscometers. His presentation focused on the correct measurement of the hardness and modulus of elasticity of surface coatings.

Photos: Robert Piterek