The BIA Group from Solingen manufactures chrome-plated plastic components for the automotive industry. The upheaval among car manufacturers and the bottlenecks in input materials are not leaving the company unscathed - but this does not dampen the innovative spirit of the plastic electroplaters from the city on the blade.

The product carrier with components is slowly lowered into the bath. After wetting and pickling in further tanks, the rectangular frame with the attached plastic parts has now reached the chromium(III) bath. Using the latest generation sulphate process, the parts are given a subtle bluish chrome look. The product carrier is then automatically removed, while a new equipped rack is already starting to pass through at the back of the hall. Everyday life in series production at BIA Kunststoff- und Galvanotechnik GmbH & Co KG in Solingen. In numerous automated processes, ABS and other plastics are turned into beautifully chrome-plated buttons, strips, knobs and much more. Four electroplating lines, including one recently commissioned for chrome(III), are used to create the visual highlights that characterize the interiors of BMW, Volkswagen, Audi and Mercedes Benz limousines in Europe and around the world. The Group's customers also come from abroad, such as BYD (Build Your Dream) from China, Volvo from Sweden and car companies from France. BIA is therefore still a shining star of successful German industrial production - despite the coronavirus pandemic, the war in Ukraine, the energy crisis and supply chain problems.

Speaking of the shiny star: the Mercedes star - the symbol of German automotive manufacturing par excellence - is also given a shiny chrome coating by the BIA Group.

Difficult framework conditions

Almost 850 production employees, developers and specialists work for the automotive supplier here in Solingen. This makes it one of the most important employers in the city of blades, normally embedded in a good upstream supply chain for technical equipment, electrolytes and plastics. However, times are difficult as there are shortages of chemicals, for example, and customers from the automotive industry are also slow to call off ordered goods. "If the cars were built as planned, we would be working at full capacity," says Dr. Felix Heinzler, Head of Development and Process Technology, about the current order situation. He and Dr. Markus Dahlhaus, a member of the BIA management team, are the kind of people who roll up their sleeves and look for solutions when things get tight. Anyone who meets them gets to know men who are energetic and enthusiastic about their job. But there is nothing to gloss over about the current situation. Markus Dahlhaus sees the supply bottlenecks as a threat to the industrial location, which are also hindering the implementation of projects at the BIA Group: When introducing a new chromic acid-free stain, for example, bottlenecks led to a delay of around eight months because the production of necessary materials in Leverkusen was halted. Dahlhaus also blames this on the REACh chemicals directive, which promotes monopolization. As a result, chemical companies only produce products that offer high margins. "Who will make something new if there are supply problems?" asks Markus Dahlhaus, pointing to the consequences of a misguided chemicals policy and stalled global trade.

Ingenuity is a must

If the potential for innovation decreases due to material bottlenecks, this is bad for the industrial location on the one hand. But it also affects the BIA Group itself. The reason: OEM developers and system suppliers, who are often unfamiliar with electroplating technology, prefer technologies with which they are familiar and so the possibilities of modern electroplating surface technology are often not fully exploited. Manufacturers such as BIA therefore have to make advance investments. Among other things, the Solingen-based company has developed transmissive electroplated switching elements and strips, which are now being produced in series. This involves interdisciplinary work - together with sign and illuminated sign masters, plastics experts, mechanical engineers, automation technicians, laser specialists and, last but not least, electroplaters. "We want an electroplated surface to do more than just look good," emphasizes Dr. Dahlhaus. The doctor of electrochemistry has been Managing Director Technology at BIA since 2011. He found the right man for projects like these a few years ago in Felix Heinzler. Heinzler has a doctorate in mechanical engineering and is an expert in plastics technology. It is thanks to his team that it is now possible to operate a switch capacitively through a chrome-plated surface. This was previously unheard of. Sensors are attached to the back of the chrome-plated switch surfaces to detect the touch surface of the component locally. Touching the symbol on the chrome surface triggers the desired function. The sensors are being developed together with a chipset manufacturer. Qualification is now almost complete - the automotive industry has already signaled tangible interest.

Making the switch to Chorm(III) difficult for suppliers

Before a plastic component can be metallized, it is first produced using an injection moulding process. And this takes place directly on site at the plant on Lotharstrasse. The sister company Biacchessi, which supplies BIA with galvanized zinc die-cast components, is located in the immediate vicinity. "Zinc die-casting in vehicles is still popular because it looks even more valuable," says Markus Dahlhaus, explaining the Group's commitment beyond the plastics sector. When injection molding plastic, the molten plastic granulate is poured under pressure into a mold specially made for the component. The material cools down in a few seconds, then a robot arm removes the part, sets it down and the cycle starts again. The process in the mold can be clearly observed from behind the machine cover. Parts fall from a nearby conveyor belt into plastic crates in time with the injection molding production cycle - in this case, raw parts for a trim strip for the Mercedes-Benz A-Class. Meanwhile, the room is acoustically filled with the humming of the machines, the buzzing of maneuvering robot arms and the rattling sound of the granulate being transported to the machines through compressed air lines. The trim strips are still coated in an electrolyte containing chromium(VI) in the further processing stages, because the conversion to chromium(III) is made difficult for suppliers, particularly through complex sampling procedures and the requirement to convert all products at the same time. "However, Audi and Daimler are slowly moving in the right direction," observed Felix Heinzler. So far, the proportion of chromium(III) in the BIA Group with its production sites in Solingen, China, Slovakia and Mexico is only around 10%. A total of 1700 employees work for the large medium-sized company worldwide.

Recipe for success Mehr-K

The base material at the Solingen plant is acrylonitrile-butadiene-styrene copolymer (ABS), an amorphous thermoplastic that is very easy to galvanize. The advantage: palladium can be deposited on its surface as a catalyst, which creates an "excellent adhesive bond" with a layer of electroless nickel, as Markus Dahlhaus describes. However, ABS alone would hardly explain BIA's success. "Our expertise in the multi-component area gives us an advantage over the competition, especially from the Far East," says Dahlhaus, revealing one of his company's recipes for success and giving an example: "Multi-component is, for example, two times polycarbonate and one time ABS. In the injection moulding machine, this leads to a three-stage process: first, the black polycarbonate is shot twice into the mould and the electroplatable ABS is placed on top with a further shot. Only a few companies have mastered this complicated process, which gives BIA a competitive advantage. "Many of our buttons with applied symbols contain clear polycarbonate at the back," says Dahlhaus, naming one of Mehr-K's areas of application.

The three laser systems are also an important part of production in Solingen. They are used, for example, to apply symbols to real chrome surfaces. Components such as these are then used, for example, as steering wheel inserts, which are used to control all kinds of functions in the vehicle. Laser technology is very efficient because only a few different tools are required. What this looks like can be seen in the Technology Center at the plant. Elsewhere in the technology center, robots load goods carriers independently on a system. This requires constant scanning. A green light pattern moves over the rack to determine the positioning of the components.

Complex waste water treatment

The major industrial issues of the future include regenerative energy supply, sustainability and the development of material cycles to conserve resources. One would think that the switch from chromium(VI) to chromium(III) for an electroplating plant is a fundamental step towards a sustainable environment. However, the effort involved in wastewater treatment has so far tended to increase, as BIA now has to destroy the complexing agents contained in the chromium(III) electrolyte with UV light and peroxide before it can start precipitating chromium(III). "Basically, more effort has to be put into the wastewater treatment of the chromium(III) electrolyte than with the chromium(VI) electrolyte in order not to pollute the environment," says Markus Dahlhaus. Nevertheless, BIA is pragmatic and sees the gradual changeover as an opportunity. In 2014, the Solingen-based company was the first German company to start series production of chromium(III) at its plant in Slovakia. Incidentally, the quality of chromium(III) surfaces leaves nothing to be desired. "Differences are only nuances in measurement technology," says Felix Heinzler.

Plans for comprehensive recycling are in place

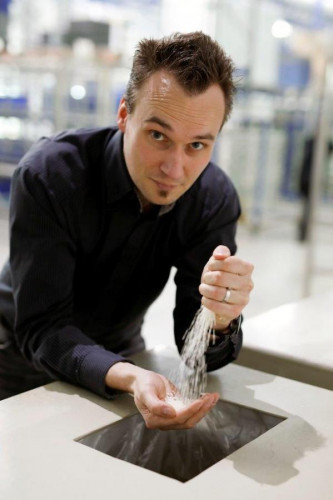

In a sustainable economy, importance is also attached to the recycling of materials. This brings the issue of recycling to the fore. And here, galvanized plastics are significantly more sustainable than painted plastics, for example, which can only be incinerated. This is because metal can be recycled again and again without any loss of quality, which also reduces dependence on primary suppliers. The BIA experts have also found a method of separating metal from plastic and reusing the plastic. "The adhesive bond between metal and plastic can be easily dissolved using cold," explains Felix Heinzler, adding "the metal is then recovered with over 99% purity using a metal separator." The crux of the matter: recycling is only successful if OEMs also dismantle end-of-life vehicles and thus get the material cycle moving. "But we are increasingly meeting with receptive ears," observes Felix Heinzler.

The Solingen-based company has also thought about its climate targets - and has already taken action: The vehicle fleet is being electrified, green electricity shares are being purchased and all roofs are being fitted with solar cells. The aim is to achieve climate neutrality by 2025, although 30% of heating requirements will continue to be covered by gas. "We have to pass on the higher costs to our customers. We try to convince them by being transparent about the costs of raw materials and energy," reveals Markus Dahlhaus. A strategy that he sees no alternative to if the company wants to survive in the long term. In the long term, there are also plans to switch to hydrogen. The two electroplating managers believe it is entirely possible to feed between 10% and 25% hydrogen into the natural gas grid.

"We believe in chrome-plated surfaces"

When it comes to the future, the BIA Group is initially driving by sight. Over the next three years, the company plans to increasingly establish a seamless production chain, further develop the touch function of buttons on chrome-plated surfaces and implement material cycles within the company. BIA is currently training 30 to 40 young people in the company, some of whom are also studying chemistry in Cologne, in order to meet the demand for specialists and managers. The electroplating group is therefore well equipped for the future in difficult times. There is also confidence in the business itself: "We believe in chrome-plated surfaces. There will still be metal in cars in the future - and if there is metal, it will be chrome-plated plastic," says Markus Dahlhaus confidently. It's a convincing plea - just as convincing as the solutions at BIA. However, in order to get off to a flying start and ensure that electroplating technology continues to have its place in decorative automotive engineering, the company would be happy to do without many a crisis in 2023. If OEMs and politicians then tweak a few things to improve the framework conditions, electroplating technology made by BIA will certainly have a bright future ahead of it.

INFO

BIA Group

Headquarters: Solingen

Turnover: 135 million euros (2021/2022)

Number of employees: 1700

Production sites: Solingen, Germany; Wuxi, China; Cab, Slovakia; San Luis Potosi, Mexico

Suppliers: BASF, Covestro, MacDermid Enthone, Atotech, Surtec, Zwingenberg, Nickelhütte Aue, among others

Minority interest: Schreiber Kunststofftechnik, Steinach (tools for plastic injection molding)

Joint venture: with BeijingWKW (2 electroplating plants and injection molding)

Material chain of metallized plastic components: From quotation to tool concepts, tools, qualification and series supply to spare parts supply

Electroplating area per day in Solingen: 3000m2

Photos: BIA Group, Robert Piterek