Electroplating shops use drums to coat screws and bulk metal goods. Progalvano from Milan is a major European supplier of this proven technology. The family-run company has reinvented itself and opened a new headquarters with state-of-the-art production facilities in 2021. This was celebrated with customers and suppliers at the "Open House" event.

At the beginning of May, the weather in northern Italy is already summery: the sky is bright blue, the sunlight glistening. The hustle and bustle of life in the metropolis of Milan has long since moved from indoors to outdoors - and tourists are also flocking to the city and its many sights. The focus of travelers from all over the world is primarily on the magnificent Duomo in the center with its towering battlements, on which stone figures look down on the historic city and its skyline.

Columned saint looking down on modern Milan from the battlements of the Duomo (Photo: Robert Piterek)

Columned saint looking down on modern Milan from the battlements of the Duomo (Photo: Robert Piterek)

It's not just culture and history that are important here. Milan is also the fashion center between the Alps and the Amalfi Coast and the industrial hotspot of the country, which continues to be known for its automotive and mechanical engineering, among other things. A lot of technological history also took place here in northern Italy: Luigi Galvani, for example, whose observations and research paved the way for the later development of the electroplating manufacturing process, came from Bologna, 200 kilometers away. In Milan, Via Luigi Galvani commemorates the great doctor, anatomist and natural scientist.

European hidden champion

Similar to Germany, family businesses often still determine economic development in Italy. This is also the case with Progalvano. The company produces more barrels for electroplating plants than all manufacturers of barrels in Germany put together - a European hidden champion whose products for the economical coating of metallic bulk material, for example, are indispensable in electroplating technology. Now, at the beginning of May, the company owned by the Cuzzolin and Premru families invited guests to an open house to mark the opening of its new headquarters and production facility in an industrial estate on the outskirts of Milan. Celebrations and a tour of the production facilities are planned.

Progalvano - the company produces more barrels for electroplating plants than all manufacturers of barrels in Germany combined

The evening before was already characterized by Italian hospitality: Over a 3-course meal, which included an exquisite pasta and ice-cold Prosecco, some of the 100 or so guests who had traveled from abroad were welcomed by Technical Production Manager Matteo Cuzzolin and German-speaking sales representative Alessandra. Matteo gesticulated as he gave an insight into the business and strategic activities of the 55-year-old company with its 35 employees, which generates an annual turnover of around 8 million euros. In between, the phone rang: Sister Francesca, Sales & Marketing Manager, was calling from Saronno, around 30 kilometers away, where she was looking after Matteo's young daughter. Division of labor in Italian - a local family business as it lives and breathes.

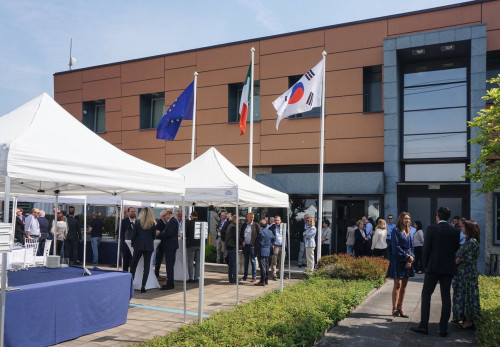

Celebrating with customers and suppliers

Progalvano's brand new, elongated business premises are immaculately decorated in brick red the next day. Freshly laid tables and chairs are placed under numerous pavilions, while caterers prepare a buffet of regional specialties in the background: Parmigiano, fritto misto, Parma ham, lots of fruit and baked goods, elsewhere bottles of wine and Aperol in front of white-clad bartenders. The European, Italian and Korean flags flutter on flagpoles in front of the entrance. The latter hangs here because of the minority shareholding of a Korean entrepreneur. The guest list includes many Italian suppliers and customers, but also representatives of the German foundry equipment specialist Fikara and Schlötter Svenska, among others.

Further expansion planned

Before the onslaught of delicacies, the program includes a tour of the production facilities. The new company headquarters and production facility covers 5000 square meters. Francesca Cuzzolin, the daughter of company founder Ferdinando Cuzzolin, is in her element here. In the sales office, she stops in front of a large world map. Most of the countries have already been covered by the Milan-based entrepreneurs: Larger white spots can only be found in Africa and the Near and Middle East. Agreements on future suppliers in Asia have recently been reached, and there are also plans to step up activities in the USA and focus on the Near and Middle East, announces Francesca Cuzzolin, praising the work of the sales team with Alessandra for the DACH region and Chiara Brambilla, who speaks Chinese among other languages, for China and the Far East. The small sales team, which also includes Export Manager Luka Premru, speaks nine languages. Premru's father, who died recently, was a passionate reader of Galvanotechnik. He is said to have collected every issue since the 1980s in his office, Francesca Cuzzolin reveals on the sidelines of the tour.

Highly automated production

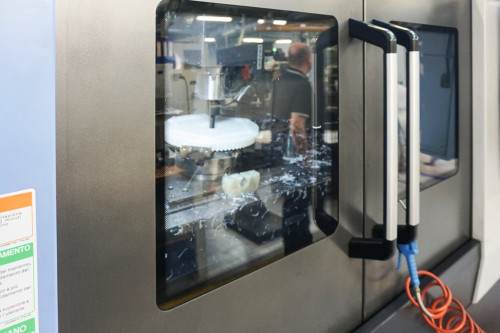

This special barrel system allows real-time data acquisition during electroplatingAglobal player with 35 employees, is that even possible? Part of the answer is revealed by looking over the shoulders of the two product designers, who simulate barrels and write CNC production programs on dual screens. Matteo Cuzzolin calls this important production step customizing, in which the drums are virtually adapted for the production of screws for spectacle frames or special applications in the aviation sector, for example. The second part of the answer is found when walking along the production line, which leads from the warehouse in several production steps to assembly and is lined with shelves of building materials. The CNC programming is automatically implemented on the numerous CNC milling machines in the hall. They shape plastic sheets made of polypropylene. Elsewhere, automated systems are used for welding, laser cutting or injection molding plastic granulate into plastic components. A total of 33 steps are required to produce the finished product, including product markings on the drums for tracking purposes. It is a highly automated, networked production process that is hidden behind the walls of the plant on Viale Lombardia.

This special barrel system allows real-time data acquisition during electroplatingAglobal player with 35 employees, is that even possible? Part of the answer is revealed by looking over the shoulders of the two product designers, who simulate barrels and write CNC production programs on dual screens. Matteo Cuzzolin calls this important production step customizing, in which the drums are virtually adapted for the production of screws for spectacle frames or special applications in the aviation sector, for example. The second part of the answer is found when walking along the production line, which leads from the warehouse in several production steps to assembly and is lined with shelves of building materials. The CNC programming is automatically implemented on the numerous CNC milling machines in the hall. They shape plastic sheets made of polypropylene. Elsewhere, automated systems are used for welding, laser cutting or injection molding plastic granulate into plastic components. A total of 33 steps are required to produce the finished product, including product markings on the drums for tracking purposes. It is a highly automated, networked production process that is hidden behind the walls of the plant on Viale Lombardia.

Real-time control possible

Matteo begins his speech in front of the almost man-sized drums arranged in rows: 3000 drums were produced last year. For a very urgent order, the delivery time was reduced from the usual 5-6 months to just 8-10 weeks. He emphasizes the quality management and precision of the drums, then moves on to assembly, where the individual parts are still largely assembled by hand on workbenches to create the finished product. The contacts for the power supply can be seen in the individual segments of the drums while workers tighten screws. The experts at Progalvano have also thought about the data requirements for the digitalization of electroplating. At the center of the assembly area is a special barrel system. It is equipped with automation that allows "real-time control" of the coating. "You know what's happening in the drum at any moment," explains Matteo. The power consumption is always in view: For example, it shows how many amps are being used for electroplating or heating.

Reach out, touch faith

Under the pavilions, the music has already started on the return to the festival area and the guests flock to the buffet and drinks stands. A three-piece band plays cover songs. Personal Jesus and Strange Love by Depeche Mode are among them, the song line "Reach out - touch faith" fills the heavy hot air in front of the Progalvano headquarters. After her father and Matteo, Francesca Cuzzolin finally takes to the lectern: "We want to celebrate the growth of the company and the new headquarters with expanded production," she says, once again emphasizing the reason for the joint celebration. In a later interview (read more on p. 958), she will use the well-known slogan "Think locally, act globally" to emphasize locally rooted production with global aspirations and, despite mixed economic and political omens in the face of crises and wars, will focus on positive thinking.

"Think locally, act globally"

Photos: Progalvano