Massive reduction in particulate matter, long service life, corrosion-free - a Hessian foundry company produces a cast-iron brake disc that is significantly more wear-resistant and environmentally friendly than conventional brake discs thanks to an extremely hard coating. However, the breakthrough on the car market is still pending.

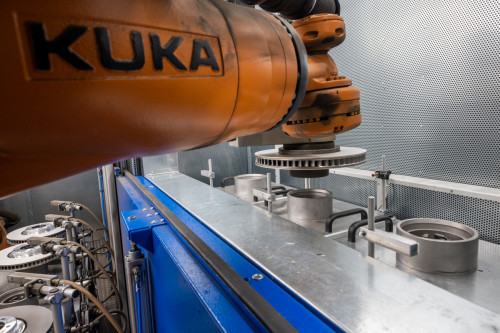

Fully automatic coating cell. Robots coat brake discs with tungsten carbide using a flame spraying process (Photos: Andreas Bednareck)The brake disc is one of the classic wear parts in cars. Several hundred million of them are required worldwide every year to ensure current mobility. And this will not change in the age of electromobility, because every vehicle needs a functional brake - regardless of the drive system. In recent years, however, not only the combustion engine but also the classic brake disc has been discredited in terms of environmental and climate protection. After all, brake discs generate fine dust pollution through gradual abrasion, which, in combination with tire abrasion and particle emissions from combustion engines, has already led to various driving bans in the inner cities of major German cities.

Fully automatic coating cell. Robots coat brake discs with tungsten carbide using a flame spraying process (Photos: Andreas Bednareck)The brake disc is one of the classic wear parts in cars. Several hundred million of them are required worldwide every year to ensure current mobility. And this will not change in the age of electromobility, because every vehicle needs a functional brake - regardless of the drive system. In recent years, however, not only the combustion engine but also the classic brake disc has been discredited in terms of environmental and climate protection. After all, brake discs generate fine dust pollution through gradual abrasion, which, in combination with tire abrasion and particle emissions from combustion engines, has already led to various driving bans in the inner cities of major German cities.

Award-winning brake disk

The innovation from the Hessian foundry offers an elegant solution. In addition to performance that comes close to a ceramic brake from motor racing, its carbide-coated brake disc reduces particulate pollution caused by abrasion by up to 90 %. Wear is also reduced by the same amount. Scoring and corrosion no longer occur at all. The latter is remarkable, because in the past, conventional galvanic coating processes or thermal spraying did not offer satisfactory results in corrosion protection for brake discs made of gray cast iron, because the protective layers do not form a sufficient bond with the cast iron.

In view of these properties, the brake disc in question was already considered promising a few years ago. After all, the issues of durability and sustainability have been gaining in importance for some time now. The technology was ready for series production in 2017. It was presented at the IAA by a well-known German luxury vehicle manufacturer and development partner under its own name. This was followed by a prestigious innovation award in 2018, which catapulted the invention into the public spotlight. However, the big success has yet to materialize. With the development of a more cost-effective variant, the foundry company will soon be making a new attempt to help the technology achieve a breakthrough and therefore does not wish to be named in connection with the discontinued product.

Tool coating for brake disks

The innovative brake disk was developed by a project team of foundry and coating experts. The aim was to transfer the properties of carbide-coated tools to brake discs. The cost of the project at the time was well into the double-digit millions.

The brake disc is manufactured in the so-called Iron Valley along the River Lahn in a smelter that was once the workplace of around 900 workers. Now the development department and the machining center for the hard metal coating of brake discs are located here, where the discs, which weigh up to 18 kilograms, are finished in highly automated interlinked processes. The raw product is produced 10 kilometers further on, where several hundred employees mainly manufacture automotive castings. The processing hall is home to an impressive array of machinery. The coating applied here is so stable that it meets the highest thermal and mechanical requirements and does not crumble. It even remains functional when it starts to glow at around 800 degrees.

Coating with one of the hardest materials

Following a basic galvanic coating with electroless nickel, the core process takes place here - the so-called HVOF coating. The four letters stand for High Velocity Oxygen Fuel - a common flame spraying process. The setting is a fully automated cell equipped with robots. In the HVOF process, tungsten carbide powder is combined with oxygen as a driver and ethylene as a catalyst to burn and melt the powder into one of the hardest materials in the world. In the high-speed flame spraying process, tungsten carbide particles hit the disk at supersonic speed, enveloping it in an aura of light for a moment. The coating is only 100 μm thick at the end and yet lasts for a vehicle mileage of around 100,000 kilometers. With a layer thickness of 300 μm, a maintenance-free brake system is therefore conceivable, which achieves the average service life of a vehicle.

In addition to the positive effects on the environment and service life, the carbide-coated brake disc also offers further potential for lightweight construction. This is because the massively reduced wear makes the so-called wear allowance superfluous. If this is dispensed with, a significant reduction in the weight of the brake disc and brake caliper is possible: between four and six kilograms of weight can be saved per vehicle, which reduces fuel consumption in combustion engines and electricity consumption in electric vehicles. In the subsequent grinding process, the brake discs are ground down to a mirror-smooth finish.

INFO

Tungsten carbide

The carbide material is used for the production of cutting tools and other highly stressed tools. It has been known since the beginning of the last century, when its hardness was often compared to that of diamonds. This is also evidenced by the early brand name Widia (like diamond) for carbide tools from the Krupp company. The resilience of the material also makes it ideal for use in military equipment, where it is used as a core material in armor-piercing bullets, among other things.

Adhesive instead of abrasive braking

The final two steps involve painting and marking with a Data Matrix code, after which the cast-iron discs are ready for dispatch. In the vehicle itself, however, the old brake cannot simply be replaced with a new one. This is because the carbide-coated brake disc no longer brakes predominantly abrasively, i.e. by removing material, but largely adhesively, i.e. through adhesion or adhesive force. "It's an attraction of molecules," says the Head of Development, explaining the braking effect, adding: "You can compare it to a wet eraser on a mirror." Different brake pads are therefore required for the new braking principle. The German luxury vehicle manufacturer therefore had to completely redesign the braking system.

Over the next few decades, the automotive industry around the world will be converting its vehicles to electric motors and fuel cells in order to reduce C02 emissions in the atmosphere. For the time being, however, we will continue to see combustion engines on our roads that also emit particulate matter - through the combustion process as well as tire and brake abrasion. In addition to safety risks, traffic will therefore continue to pose health risks such as cancer and respiratory diseases. Hard metal-coated brake discs are a step towards more liveable inner cities. Thanks to their significantly longer service life, they are also more sustainable and therefore better products. Their widespread introduction would therefore be desirable.

INFO

HVOF coating

The High Velocity Oxygen Fuel process is used in the aviation, automotive, paper and mechanical engineering industries. It takes place under high pressure inside a water- or air-cooled combustion chamber. It is interesting to note that the spray material is only slightly changed metallurgically by the process. There are now also other methods for reducing brake disk wear. High-speed deposition welding promises similar results in brake disc coating as the HVOF process.