The hydra of inflation is back and poses major challenges for surface technology. Rising energy prices have been keeping the energy-intensive industry busy for some time now. Material shortages have also accompanied companies through the coronavirus crisis. However, raw material prices have been rising rapidly since the Ukraine war. Using ERP systems, electroplating companies can adjust prices and justify them plausibly to customers.

It is not (or no longer) possible to absorb price developments on the purchasing side, which means that price increases have to be passed on to customers. This poses major challenges for companies and raises the question: how can the reasons for a necessary price increase be communicated and what procedures are conceivable?

How has inflation worked so far?

In normal times with a moderately growing economy, there is a certain level of inflation that makes it necessary to adjust the prices of one's own products from time to time. The Governing Council of the ECB has set an inflation target of 2%. It is argued that this inflation rate is the best way to ensure price stability. The Eurosystem is supposed to guarantee this price stability. Achieving this target for individual prices is proving difficult. Therefore, the price level is considered - the average of all prices. This is calculated from selected everyday goods and services that are grouped together in a basket of goods. The prices of the goods are determined on a monthly basis and the average is calculated. This results in a trend for the price level.

Changes in quality, improved performance and further development of products make it difficult to compare them with products from several decades ago on the basis of price alone. The smartphone, for example, is an extreme case. It is obvious that a current smartphone cannot be compared in price with a cell phone from the last century. In these cases, it is appropriate to use hedonistic methods for quality adjustment. The method evaluates a slight price increase with a simultaneous extremely high increase in performance as a cheapening of the product.

The inflation rate determined using the basket of goods is not directly related to the industrial producer price index, but is very similar under normal circumstances. An orientation towards a moderate inflation rate is therefore a sensible approach for price increases. Although individual product or surface types are still differentiated, increases are made in a simple manner using a small percentage.

The causes of today's inflation

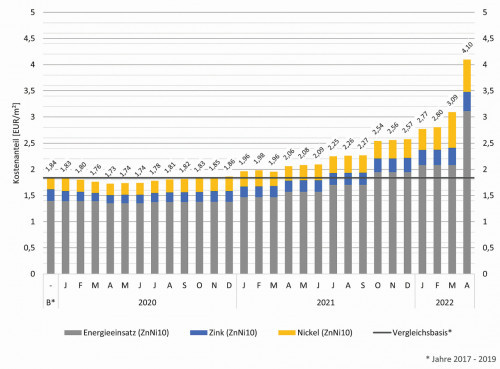

Figure 1: The inflationary trend in electroplating plants can be seen in the increased cost shares for nickel, zinc and energy, among other thingsToday,inflation (April 2022 at 7.4 %) is again well above the target of 2 %. In recent years, the Eurosystem has tried to bring inflation from well below 2% closer to its target. The instruments only had a limited effect; however, the current situation cannot be explained by a ketchup effect - after a little comes a lot, the behavior of non-Newtonian fluids - but a whole series of inflation drivers unrelated to monetary policy are making themselves felt.

Figure 1: The inflationary trend in electroplating plants can be seen in the increased cost shares for nickel, zinc and energy, among other thingsToday,inflation (April 2022 at 7.4 %) is again well above the target of 2 %. In recent years, the Eurosystem has tried to bring inflation from well below 2% closer to its target. The instruments only had a limited effect; however, the current situation cannot be explained by a ketchup effect - after a little comes a lot, the behavior of non-Newtonian fluids - but a whole series of inflation drivers unrelated to monetary policy are making themselves felt.

- Corona pandemic: lockdown, labor shortages, transport problems and supply bottlenecks have severely strained supply chains and led to sometimes significant price increases due to the bottlenecks (interruption of the supply chain)

- Restoration of the temporarily reduced VAT rate: To combat the economic consequences of the coronavirus pandemic, VAT rates were temporarily reduced and have now been restored to their previous level

- Energy prices: High prices on the international energy markets are a persistent driver of inflation, with price increases in 2022 exacerbating the problem

- Metal commodity prices: The first coronavirus lockdown in April 2020 triggered a brief slump in commodity prices. Since then, commodity prices have risen continuously and in some cases significantly above pre-crisis levels. However, the rise in industrial commodities is particularly impressive

- Government regulation: minimum wage,CO2 pricing and environmental protection requirements (REACh) are also driving inflation

- War in Ukraine

- Rational expectations: The reactions of the economy also play a role. If the mathematically calculated models and predictions are considered valid, we speak of rational expectations. Companies, for example, also react to rising inflation in line with this expectation.

This means that part of the price increase can be attributed to the pandemic, government regulation and imported inflation.

Surcharges instead of price increases

When the development of commodity and energy prices is very dynamic, you have to react quickly. But simply raising prices and renegotiating prices with customers is not only costly, but also only partially effective. Ultimately, you need to be clear about your long-term expectations. Because when prices calm down and normalize again, it will be necessary to lower customers' prices again.

Surcharges are a practical tool to avoid constant negotiations. They have several advantages: they can be adjusted flexibly, are transparent for customers and convey the message that this is a temporary measure.

The question now arises as to whether the ERP system supports this, because of course you don't want to touch every item when the surcharge percentages change. For quick and easy implementation, it is advantageous to store different global percentages for the different types of surcharges, which basically apply directly to all customers. This approach allows different surcharges to be combined depending on the situation - for example, for transportation costs or chemicals used. It is then possible to determine which surcharges should apply to individual items. If the amount of a surcharge changes, this adjustment is transferred to all customer data records. However, exceptions, such as special conditions, should always be stored directly with the respective customers.

To give customers a quick overview of the posted surcharges, these should be displayed per item on the invoice. The transparency of the negotiated price is maintained and all surcharges are clearly communicated. However, it should be noted that many merchandise management systems have difficulties posting surcharges or discounts.

To reduce the maintenance effort in the customer's ERP system, it may be possible to set the surcharges higher and fix a certain period of time for them.

All in all, surcharges - if supported by the ERP system - are a flexible system for reacting to unstable prices, which also increases transparency for the customer.

Precious metals

If certain raw materials are very expensive and prices are volatile, they should be calculated at daily prices. This procedure is widely used by companies that process precious metals. The price of an item is divided into two components for better understanding. The forming or shaping costs include the pure processing and the processed precious metal is charged at daily rates. The customer thus sees the molding costs, which always remain reliable and stable over a long period of time, and on the other hand the volatile precious metal prices.

Now that the prices of other metals, such as nickel, have risen sharply and become volatile, the question arises as to whether they should be treated in the same way in the settlement, i.e. settled at the daily rate. But - shouldn't this also apply to other volatile price components?

The differentiated calculation

Creating transparency in precious metals simplifies price negotiations, as no one can seriously start haggling over metal prices.

If your expectation is that the prices of the individual components will develop very differently, then it makes more sense to calculate more precisely instead of using surcharges.

The production costs are made up of

- Wages/labor costs

- Costs for plant and machinery

- Costs for goods such as chemicals and metal

- energy.

In addition to the pure costs, material, production, administration and sales overheads and a reasonable profit margin must also be taken into account.

A suitable ERP system can provide support in many areas:

- An automatic calculation of the area of the article, together with the desired layer thickness, is used to determine the metal weight, possibly with a certain amount of shrinkage during processing.

- For each system, costs per product carrier, drum or batch are calculated from the various system costs and the output in performance units (drum, product carrier, ...).

- The costs per part or per price unit are calculated from the item-specific data (piece / WT or kg / Tr) and the costs per unit of output.

- The costs per unit of output are changed from production-related parameters such as flows or changed processing times.

- The carryover quantity per unit of output is calculated using a simple carryover classification based on the area, the specification and a carryover factor.

- The carryover can be used to calculate dynamic bath maintenance intervals and also to calculate chemical consumption.

- Two cost rates are available for the cost calculation for each system, so that a full and partial cost calculation can be carried out.

- The requirement for consumables can be entered in a parts list or recipe.

- The sum of the individual costs results in the total production costs on a full or partial cost basis.

- If there are changes in the basic costs, all affected items can be calculated with the new costs.

The calculation of an article on the basis of work plans, specifications and technical parameters offers further advantages. The specifications can be used to support planning and automate machine allocation.

TheCO2 footprint of each article can also be calculated with little effort. In previous years, theCO2 footprint was often ridiculed. Today, theCO2 certificate in offers provides a clear competitive advantage.

Even if the items have been calculated accurately and sharply using these methods, there are still risks that the price may not be adequate in certain cases. Deviations in order processing that do not correspond to the assumed production process and unfavorable order quantities lead to additional costs that must be compensated.

The customer should therefore also be obliged to deliver the order quantities in accordance with the optimum production batch sizes. If the customer does not deliver in a multiple of the optimum batch size, drums that are not completely filled or insufficiently hung racks cannot be produced to cover costs.

Optimal batch sizes

In barrel electroplating, it is particularly important that barrels are filled as completely as possible. This is because the price per kilogram for this type of surface finishing is in the lower two-digit cent range and, in order to be able to produce economically, unsuitable batch sizes must be absorbed as well as possible.

If the order quantity is so unfortunate that the last drum is only partially filled, the residual quantity avoidance strategy can be used from a quality assurance perspective.

The fill quantity of the last drum is distributed evenly to all other drums, and the adjustment of the flow is also taken into account. The remaining quantity is dissolved; a drum with a low fill level at the end of the order is avoided.

From a commercial point of view, it is good if there is not only a flat minimum price for a small quantity, but several staggered minimum prices offer the possibility of covering relatively small quantities, for example the first three or four drums.

These special functions could ensure that barrel plating plants can produce economically and efficiently even with unsuitable batch sizes and sharply calculated prices.

This approach, which makes sense for barrel plating, can also be used for rack plating. Not every customer accepts that the bath occupancy is billed if they have previously been offered unit prices. Particularly with hard chrome, the customer wants unit prices and, from a technical point of view, product carriers or fixtures cannot be run with mixed items.

A comprehensible and plausible billing method is to bill the articles from fully hung product carriers at the normal price and to distribute the costs of a fully hung product carrier to the reduced quantity for the last product carrier that is not fully hung.

The customer sees his usual or offered price and will understand that the last parts are more expensive if they do not form a complete product carrier.

Ultimately, the importance of the technical specifications in the work plans becomes apparent in order to achieve reliable, commercially correct prices.

If items are calculated in this way, the effect on the item price can be recalculated automatically and very precisely in the event of raw material and energy price increases.

ERP systems can record and calculate many factors in great detail. However, these prices often do not have to and cannot be offered to the customer. A sure instinct is therefore still required. The question is whether it is better to constantly confront the customer with small price increases caused by the volatility of the individual components or to come up with a one-off, higher price increase that promises the customer a certain degree of planning security.

FOR INFO

Surcharges

General surcharges:

Fuel, energy, environment

Surface-specific additives:

Nickel, tin, zinc, zinc-nickel

The appropriate surcharges can be automatically activated for an article depending on the surface or processing code.

Minimum quantity prices

Minimum quantity prices can be defined, which automatically result in a flat rate price for up to three drums based on the quantity requested. If a customer asks for an order quantity of 40 kg with a drum filling quantity of 50 kg, the all-inclusive price for one drum is calculated, for example 50 euros. If we stay with the same example, it works in the same way for two or three drums, i.e.: 85 kg costs 100 euros; 110 kg costs 150 euros. In this example, the normal price per kilogram only applies for quantities over 150 kg.

Non-optimal batch size

The technical calculation of an item is always based on an optimum batch size for production. A problem in the supply chain can be the delivery of a non-optimal batch size.

If incompletely stocked goods carriers are run in the systems, this inevitably results in a shortfall. For example, if the optimum batch size for a piston rod is 4 pieces and the customer sends an order with 8 piston rods, the quoted price of EUR 20.00 per piece covers the costs. If the customer delivers 9 piston rods, the order could not be produced at a cost-covering price of 180.00 euros. In this case, the piston rods on the full product carriers would have the standard price and the rest would be more expensive. In this case, 8 piston rods would be invoiced for 20 euros and one piston rod for 80 euros.

Price quality lists

The quality of a price can be quantified with a suitable evaluation. To determine this price quality, the revenue of an item is compared with its production costs for a selected period. A "price quality" quotient is determined for the item (revenue/cost). If the price quality is less than 1, the price must be increased. If the list is sorted per customer according to item turnover and a price quality of less than one appears at the top of the list for the top-selling items, it is immediately clear where action is required. A price quality list is a good tool for price negotiations.