It is expected that there will be 10 million self-driving cars on Europe's roads by 2030 - and almost twice as many on China's roads. This requires 360° real-time detection. The required three-dimensional radar sensor technology, which can be freely selected in terms of shape, was developed in a research project using panel level molding technologies.

By 2030, 10 million self-driving cars are expected on Europe's roads - and almost twice that number on China's. This requires 360° real-time sensing. The required three-dimensional radar sensor technology, which can be freely selected in shape was developed in a research project using panel level molding technologies.

In order to ensure the highest level of safety in automated driving, the KoRRund project ('Conformal and multistatic MIMO radar configurations for radar surround view for automated driving') developed 3D radar modules that can be positioned relatively freely on the vehicle and, integrated into a sensor network, enable 360° all-round visibility. This enables them to analyze their surroundings in real time and from all perspectives simultaneously. For this seamless mapping of the environment, researchers at Fraunhofer IZM, together with project partners, have developed packaging processes for reliable radar sensors with revolutionary free-form surfaces, which will make it possible to realize any antenna shape and mounting on the vehicle in the future.

There are expected to be 10 million self-driving cars on European roads alone by 2030 - and almost twice as many in China. The trend is inevitably moving towards automated driving, as the advantages are obvious: more efficient road traffic thanks to vehicle networking, comfort and time savings for passengers and, above all, increased safety while driving. After all, most road accidents happen due to human error. To ensure this safety, automated vehicles are equipped with radar sensors that scan and process their surroundings. As these sensors currently have a flat design and are preferably fitted to the front and rear of the vehicle, they usually monitor an area of 180°. But what if a completely seamless coverage of the surroundings could be ensured?

In order to realize just such a 360° real-time detection and thus guarantee the recording of the smallest objects and creatures from different perspectives, researchers in the KoRRund project overcame the existing barriers to radar development and researched new approaches to spatial resolution and target classification.

Fraunhofer IZM played a key role in the development of the sub-project, in which mold technologies for 3D radar sensor technology were simulated, constructed and tested. In order to develop optimal high-frequency antennas with the methods of maximum integration, the three technology partners of the sub-project - Bosch, Schweizer Electronic AG (SEAG), Fraunhofer IZM - individually developed solutions that were evaluated together with the Karlsruhe Institute of Technology (KIT) with regard to their HF suitability. Bosch application partner Inmach Intelligente Maschinen GmbH, Ulm University of Applied Sciences and Ulm University were also involved.

Transfer to the third dimension

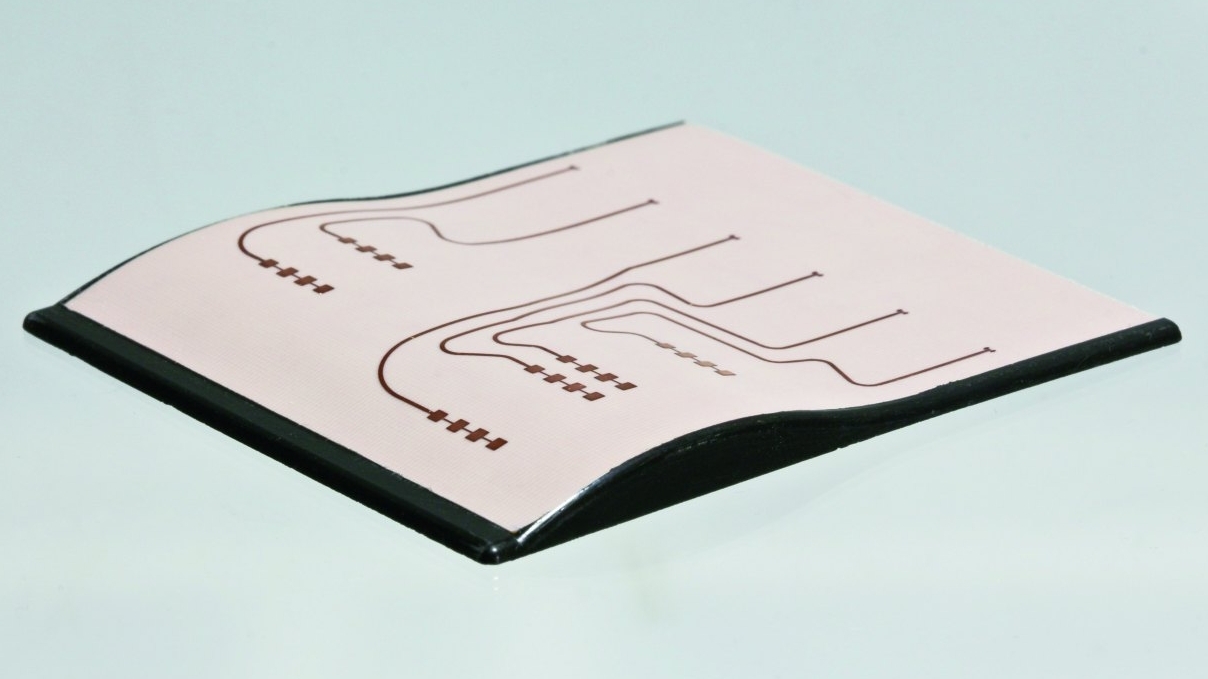

The research focus of SEAG and Bosch in KoRRund was the transfer from the two-dimensional to the third dimension through the introduction of flexible areas, i.e. the realization of foldable superstructures based on established manufacturing technologies. Here, Fraunhofer IZM took a promising path towards 3D structured radar modules based on compression mold technology.

The researchers encapsulated the previously planar high-frequency substrate in a curved form so that no further fixation is necessary afterwards: a free-form surface was created for antennas that can be used at 76 GHz and at the same time require only a minimum of installation space. With the help of a special encapsulation system, it is possible to simultaneously back-mold the assembled substrate and overmold a high-frequency circuit mounted on the substrate, i.e. to protectively overmold it and - in the case of flip chips - to underfill it.

This means that almost any geometry of robust and cost-effective 3D antennas can be realized and also produced in large quantities. This technology can be useful not only for all-round visibility on the car, but also in a wide variety of antenna designs. From round and angular to very special shapes - this free-form technology can be used for industrial applications in almost all areas of radar, optics and sensor technology.

The KoRRund project was successfully completed at the end of 2020 after a project duration of three years. The project partners worked together under the coordination of Bosch. The project was funded by the German Federal Ministry of Education and Research with a total of 4.6 million euros. The technical contacts at IZM in Berlin are Thanh Duy Nguyen (+49 30 46403-238,

The Fraunhofer IZM

It is invisible - but indispensable: nothing works without highly integrated microelectronics and microsystems technology. The basis for their integration into products is the availability of reliable and cost-effective assembly and connection technologies. Fraunhofer IZM is a world leader in the development and reliability assessment of electronic packaging technologies and provides its customers and industrial partners with customized system integration technologies at wafer, chip and board level. Research at Fraunhofer IZM contributes to making electronics more reliable and providing reliable statements on the durability of electronics.