Providing hearing-impaired people with cochlear implants based on microelectrode arrays is nothing new. It has been done for decades and has helped around 700,000 people so far. However, a further 460 million people worldwide are affected. Instead of being produced manually, the arrays would have to be manufactured industrially in large quantities. The Korean company Todoc has set itself this task. In terms of production technology, the team, which comes from high-ranking university and research institutes in the fields of brain research, biotechnology and microelectronics, relies on an ultrashort pulse laser system from Germany.

Cochlear electrode arrays with 32 channels manufactured with LPKF ProtoLaser RProvidingpeople with impaired hearing with cochlear implants based on microelectrode arrays has been done for decades, and around 700 000 people have been helped in this way so far. But another 460 million people are affected worldwide. Instead of being produced manually, the arrays would have to be manufactured industrially in large quantities. This is what the Korean company Todoc has made its mission. The team coming from high-ranking university and research institutes in the disciplines of brain research, biotechnology and microelectronics, relies on an ultrashort-pulse laser system from Germany for its production technology.

Cochlear electrode arrays with 32 channels manufactured with LPKF ProtoLaser RProvidingpeople with impaired hearing with cochlear implants based on microelectrode arrays has been done for decades, and around 700 000 people have been helped in this way so far. But another 460 million people are affected worldwide. Instead of being produced manually, the arrays would have to be manufactured industrially in large quantities. This is what the Korean company Todoc has made its mission. The team coming from high-ranking university and research institutes in the disciplines of brain research, biotechnology and microelectronics, relies on an ultrashort-pulse laser system from Germany for its production technology.

A cochlear implant is an electronic medical device that is surgically implanted and gives people with hearing impairments the ability to hear. The technology itself has been available for several decades and has so far helped around 700,000 people to hear or restored their hearing.

However, a further 460 million people worldwide are affected by hearing loss. Over 60,000 cochlear implants are sold every year. But in India and China alone, at least 60,000 children are born deaf every year. The cost per implant is currently between 17,000 and 24,000 euros, as the microelectrode array that is implanted in the cochlea is manufactured and inserted manually.

Specialists found start-up

Cochlear electrode arrays with 32 channels manufactured with LPKF ProtoLaser RTodocwas founded back in 2015 to address the global shortage of cochlear implants. The company has set itself the task of developing machine-manufacturable cochlear electrode arrays. The leading minds behind the company are founder and co-owner Abraham Kyousik Min

Cochlear electrode arrays with 32 channels manufactured with LPKF ProtoLaser RTodocwas founded back in 2015 to address the global shortage of cochlear implants. The company has set itself the task of developing machine-manufacturable cochlear electrode arrays. The leading minds behind the company are founder and co-owner Abraham Kyousik Min

- Lee Hoseung (CTO), who worked in deep brain stimulation research and for Mentor Graphics Korea after studying electronic engineering and 8 years at Samsung

- Jin Won Kim (CRO), who worked at KBIO Health, a Korean state-owned medical technology development center, after studying electronic engineering and writing his doctoral thesis, researched cochlear implants for several years, and worked in an inter-university semiconductor research institute in the field of dry-etching

- Woojin Ahn (CPO), who moved from the Korea Advanced Institute of Science and Technology (KAIST) to chip design at Samsung Electronics eight years ago before joining Todoc, and

- Doo Hee Kim (CSO), who studied Biomedical Engineering at Yonsei University and Medicine/Neurosurgery at Seoul National University and has dedicated 5 years to electronic cochlear implants.

Conventional cochlear implants

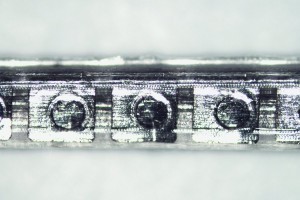

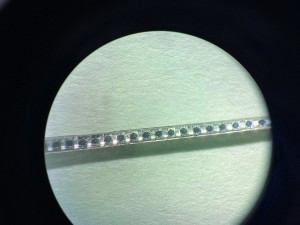

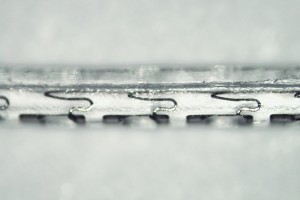

32-channel cochlear electrode arrays fabricated with LPKF ProtoLaser RAconventional cochlear electrode array consists of 16 to 22 electrode contacts made of platinum alloy and leads embedded in medical grade silicone. The maximum dimensions are 0.4 mm to 0.8 mm in diameter and 20 mm in length.

32-channel cochlear electrode arrays fabricated with LPKF ProtoLaser RAconventional cochlear electrode array consists of 16 to 22 electrode contacts made of platinum alloy and leads embedded in medical grade silicone. The maximum dimensions are 0.4 mm to 0.8 mm in diameter and 20 mm in length.

This number of electrodes and leads set a pioneering new standard 20 years ago. Since then, there have been many attempts to produce the cochlear electrode array using a semiconductor manufacturing process. Unfortunately, however, the base material and the process suitable for the semiconductors are not biocompatible.

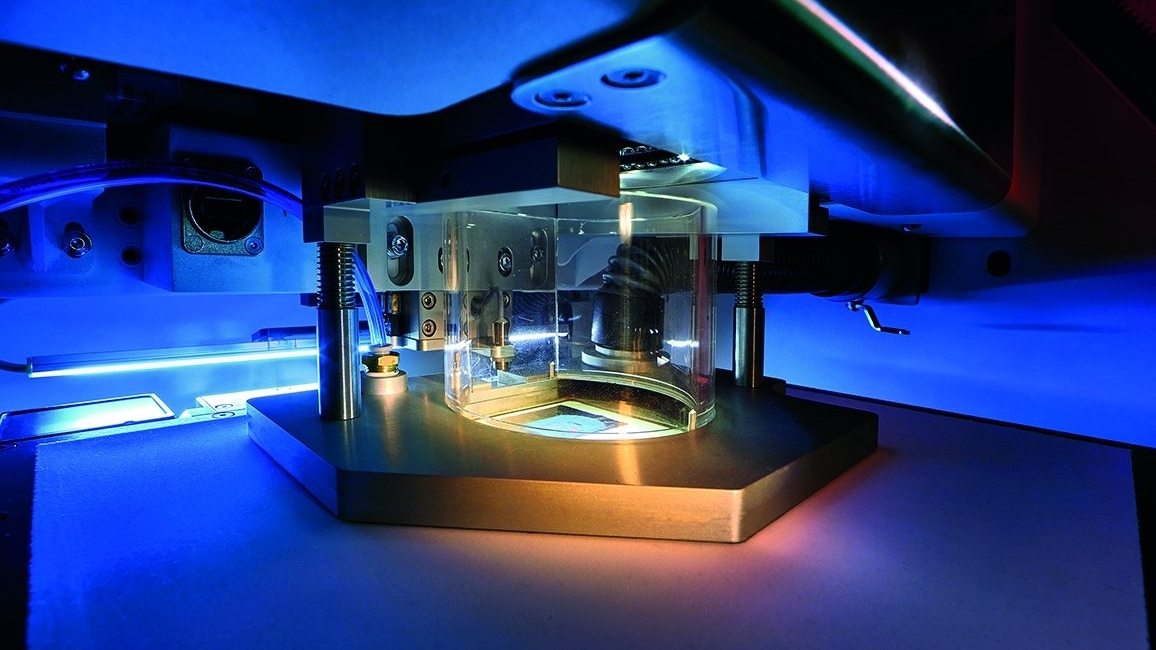

Todoc began using the LPKF ProtoLaser U3 in 2016, followed two years later by the LPKF ProtoLaser R ultrashort pulse laser system, to produce microstructures on a platinum alloy foil. Thanks to these laser systems, Todoc has recently succeeded in placing as many as 32 channels on a biocompatible alloy. Production was automated as far as possible. This means that all 32 channels can now be produced in a single pass.

Abraham Kyousik Min and his colleagues have structured lines with a width of 16 µm at a distance of 32 µm on the platinum foil and integrated contacts and connecting leads for 32 channels in just one process step - instead of manufacturing electrodes for 22 channels manually. For the finished electrode array, only individual process steps are required to encapsulate the contacts and leads. With this manufacturing process, Todoc has developed and launched the first commercially available cochlear electrode array with 32 channels.

The new system was initially launched on the South Korean market in 2021. The company is now planning to expand its sales network worldwide. It aims to make cochlear implantation surgery available to people in developing countries who are unable to receive cochlear implants due to the current mismatch between supply and demand in today's market environment. The aim is to be able to help people on all continents - without cost restrictions.