Injection-molded interconnect devices (MIDs or mechatronic integrated devices) enable complex 3D functional integration in a minimal installation space and therefore qualify for various applications in areas such as automotive and medical technology as well as communication and information technology. With the increasing use of MID technology, the aspect of process reliability is becoming just as important, which poses challenges for the MID industry. The following article deals with the question of how greater process reliability can be achieved in the manufacture of laser-direct structured MID components.

Molded interconnect devices (MIDs) enable complex 3D functional integration in a minimum of space, making them suitable for a wide range of applications in areas such as automotive, medical technology, communications and information technology. With the increasing use of the MID technology, the aspect of process reliability is becoming equally important, which presents challenges for the MID industry. The following article addresses the question of how a higher process reliability can be achieved in the production of laser direct structured MID components.

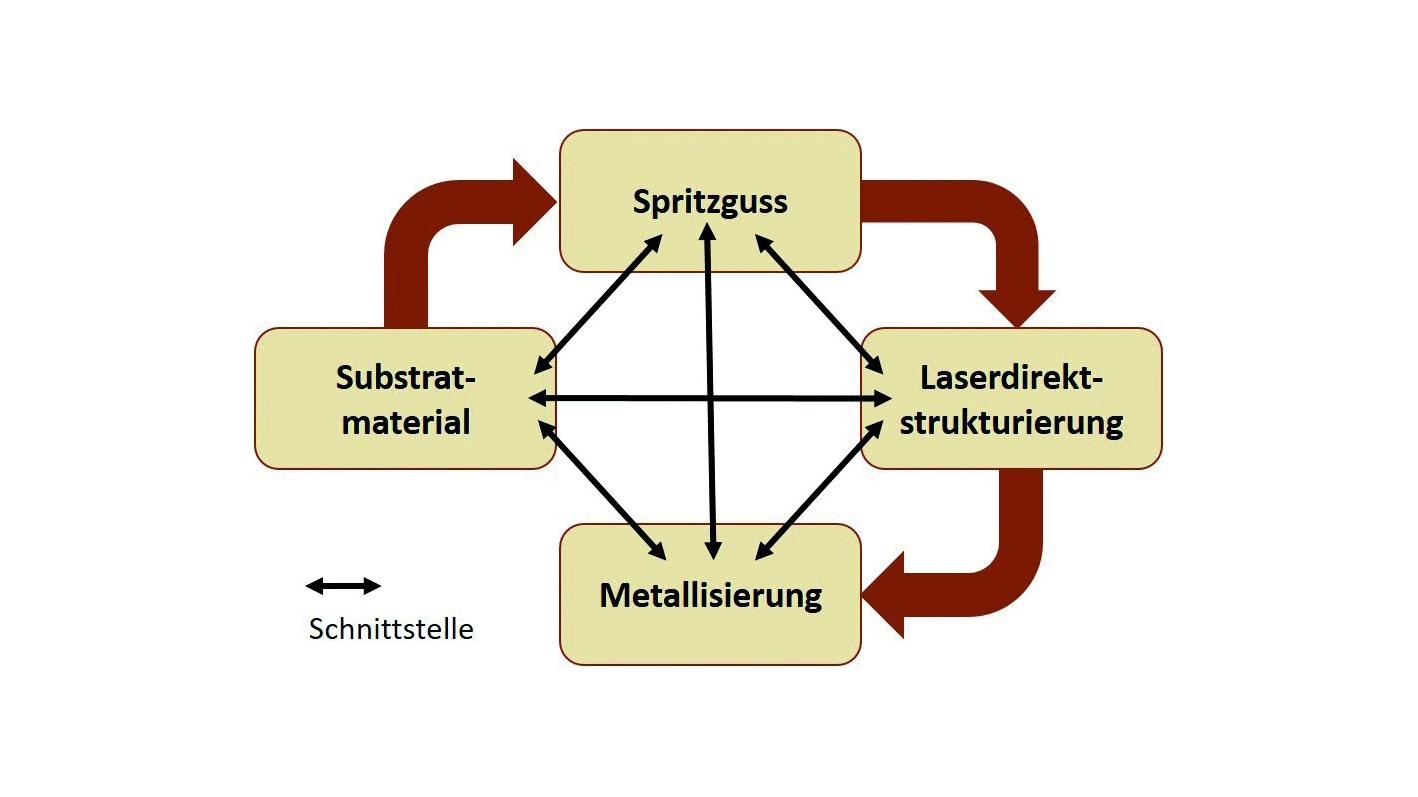

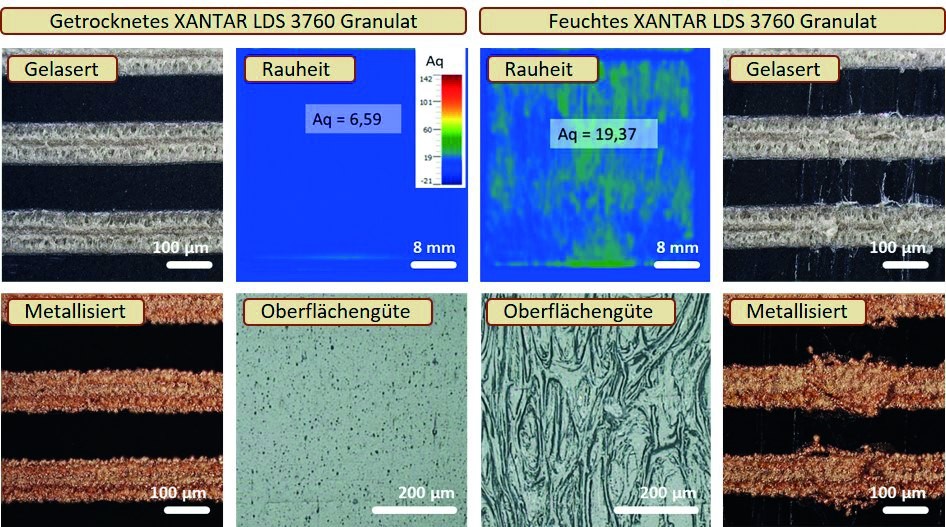

One of the challenges lies in the current lack of standardization of the interfaces in the process chain. These are shown schematically for laser direct structured MID in Figure 1. They illustrate that all process steps are mutually dependent. For example, the drying of the injection molding granulate has an influence on the injection molding process and the component quality that can be achieved. If the surface quality is inadequate, this can lead to extraneous metallization and, in the worst case, to short circuits between conductor tracks(Fig. 2). Moisture absorption, processability and the surface quality to be achieved depend heavily on the substrate material selected. Figure 2 on the right shows a component surface made from the polycarbonate XANTAR LDS 3760, where the injection molding granulate was deliberately processed in a moist state. Although the material can still be processed well, the resulting component surface is heavily furrowed. In contrast, LCP Vectra E840i LDS, a mineral-filled, liquid crystalline polymer, although it can absorb comparatively less moisture, is significantly more difficult to process in a moist state. Nevertheless, significantly more homogeneous surfaces can be achieved if the process is adapted to the material.

Fig. 2: Influence of granulate drying with XANTAR LDS 3760 on the quality of the component surface and the associated processability with regard to laser direct structuring and metallization. The variance of the angular distribution of scattered light, Aq, plotted two-dimensionally in the false color images is a process-integrated characteristic value for the surface microstructure

Fig. 2: Influence of granulate drying with XANTAR LDS 3760 on the quality of the component surface and the associated processability with regard to laser direct structuring and metallization. The variance of the angular distribution of scattered light, Aq, plotted two-dimensionally in the false color images is a process-integrated characteristic value for the surface microstructure

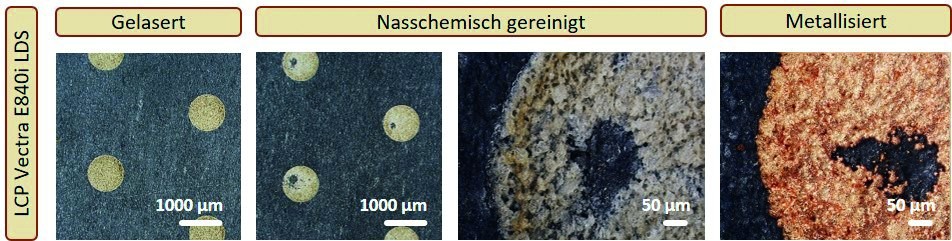

The example shows that precise knowledge of all process steps and their interactions is essential in order to achieve high component quality. It is also important to take a close look at supposedly simple intermediate steps in the process. One specific example is the cleaning of components after laser direct structuring. This is usually carried out in order to remove particulate laser debris, which can otherwise also lead to foreign metallization. Wet-chemical ultrasound-assisted cleaning is usually chosen for this. On substrate materials such as LCP Vectra E840i LDS, which is deliberately roughened by laser direct structuring, too harsh or inhomogeneous ultrasonic treatment can result in defects in the structured areas, which subsequently cannot be metallized or can only be metallized insufficiently(Fig. 3). Here it is essential to find a balance between the highest possible cleaning performance and the lowest possible component load.

Through the combined use of destructive target preparations (e.g. microtome sections or cross-sections for scanning electron microscopy) and non-destructive analysis methods (e.g. microscopy or roughness measurements), influencing factors can be identified so that the occurrence of defect patterns, such as defects in the metallization, can be minimized and process control can be optimized. The correlation of process and analysis results obtained in this way makes a significant contribution to increasing process reliability in the manufacture of laser-direct structured MID components.

Fig. 3: Defects in structured areas on LCP Vectra E840i LDS, which are due to excessive cleaning in the ultrasonic bath and which cannot be metallized

Fig. 3: Defects in structured areas on LCP Vectra E840i LDS, which are due to excessive cleaning in the ultrasonic bath and which cannot be metallized

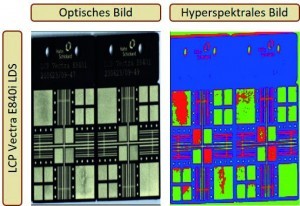

Fig. 4: Results of an automated hyperspectral camera image analysis. The areas highlighted in red within the required metallized areas can be directly assigned to streaks in the sample photoIn addition,some non-destructive analysis methods are also suitable for measurements during production and thus qualify for the standardization of interfaces in the process chain. The results of an optical roughness measurement as one of these inline-capable analysis methods are also shown in Figure 2. With the help of a so-called scattered light sensor, complete components can be examined for their surface quality in the shortest possible time. This makes it possible to make statements about suitable injection molding parameters during process development and to derive possible effects on further processability during production. This inline-capable analysis method therefore increases process reliability in injection molding as a structuring step, but is less meaningful for layer-forming process steps, for example. Alternative methods can be used here. One example of this is measurements with a hyperspectral camera. This makes it possible to obtain information on large wavelength ranges of the electromagnetic spectrum for each individual pixel. This method can be used after metallization, for example. Any streak-like deposits on the surface, which can be problematic for subsequent assembly with electronic components, can be detected automatically(Fig. 4). The hyperspectral camera thus provides an objective quality classification.

Fig. 4: Results of an automated hyperspectral camera image analysis. The areas highlighted in red within the required metallized areas can be directly assigned to streaks in the sample photoIn addition,some non-destructive analysis methods are also suitable for measurements during production and thus qualify for the standardization of interfaces in the process chain. The results of an optical roughness measurement as one of these inline-capable analysis methods are also shown in Figure 2. With the help of a so-called scattered light sensor, complete components can be examined for their surface quality in the shortest possible time. This makes it possible to make statements about suitable injection molding parameters during process development and to derive possible effects on further processability during production. This inline-capable analysis method therefore increases process reliability in injection molding as a structuring step, but is less meaningful for layer-forming process steps, for example. Alternative methods can be used here. One example of this is measurements with a hyperspectral camera. This makes it possible to obtain information on large wavelength ranges of the electromagnetic spectrum for each individual pixel. This method can be used after metallization, for example. Any streak-like deposits on the surface, which can be problematic for subsequent assembly with electronic components, can be detected automatically(Fig. 4). The hyperspectral camera thus provides an objective quality classification.

In addition to the correlation of process and analysis results, the targeted use of production-accompanying analysis methods at important interfaces in the manufacturing process enables a further increase in process reliability in the production of high-quality MID components.

The results shown were obtained as part of the project 'Production-accompanying surface characterization to increase quality and efficiency in the production of complex plastic-based mechatronic assemblies', FOQus for short. The IGF project no. 20653 N of the research association Hahn-Schickard-Gesellschaft für angewandte Forschung e. V. was funded via the AiF within the framework of the program for the promotion of joint industrial research and development (IGF) by the Federal Ministry for Economic Affairs and Energy on the basis of a resolution of the German Bundestag. We are grateful for this support. The project team would like to thank the project support committee for their support and valuable advice from the numerous discussions.

Contact:

Dr. Andrea Knöller, Phone +49 711 685-84784,

A

(MID process chain)

Dr. Michael Noeske, Phone +49 421 2246-475,

m

(Surface characterization)