Printing technologies can be used to produce SCs (supercapacitors) with the advantage of precise control over their geometric shape, thickness, composition and physical properties - at low cost, minimal environmental impact and high compatibility with substrates. The performance of screen printed SCs is highly dependent on the ink used during the printing process. [1, 2] It is important to research optimal materials for the formulation of efficient inks. A recent study shows how screen printing can be used to produce electrodes with carbon-based polymer composite inks using a non-toxic chitosan binder.

Printing technologies can be used to produce SCs (supercapacitors)with many advantages, including precise control over their geometric shape, thickness, composition and physical properties, low cost, minimal environmental impact and high compatibility with substrates. The performance of screen-printed SCs is highly dependent on the ink used during the printing process [1, 2]. It is important to explore the optimal materials for the formulation of efficient inks. A recently published study shows how screen printing can be used to produce electrodes with carbon-based polymer composite inks using a non-toxic chitosan binder. This could pave the way for sustainable and commercial energy storage applications of screen-printed SCs.

Description of the research project

Polyaniline (PANI)/carbon (CDC) was synthesized by in situ chemical oxidative polymerization of PANI in the presence of CDC. Conductive electrode inks were prepared using an environmentally friendly chitosan binder in an aqueous medium. Subsequently, symmetrical supercapacitors (SCs) were prepared by both doctor blade coating and screen printing techniques.

The electrical conductivity, morphology, specific capacitance and energy density of these composites were investigated for their applicability as SC electrodes. Pure PANI with chitosan as a binder could not be printed due to its brittleness, while the presence of CDC enables the production of smooth films suitable for electrode fabrication. The fabricated composite electrode has a higher specific capacitance (up to 419 F g-1) and higher energy density (up to 6.7 W h kg-1) than the original CDC electrode. The capacitance of the screen-printed SCs was 440-470 mF with an equivalent series resistance of about 27 Ω.

Introduction

Previous studies have shown that conductive polyaniline-carbon composite ink patterns can be fabricated by screen printing for various applications. To date, several related studies have reported AC, CNTs, and graphene coated with PANI. However, there are fewer publications on the in situ fabrication of PANI/CDC composites by chemical oxidative polymerization [3].

In this study, PANI/CDC hybrid composites were prepared by in situ chemical oxidative polymerization with different monomer-to-carbon ratios. Printable water-based ink materials were prepared from these composites using environmentally friendly chitosan as a binder. As far as we are aware, the use of an environmentally friendly and water-based chitosan binder for the production of this particular type of electrode material and its printability has not yet been addressed. The results show that the addition of CDC improves the processability of PANI-containing inks and enables the fabrication of electrodes by doctor blade and screen printing techniques. In our study, the electrochemical performance of these electrodes is discussed in detail.

Structural formula of chitosan, a biopolymeric derivative of chitin derived from crustacean shells

Structural formula of chitosan, a biopolymeric derivative of chitin derived from crustacean shells

Preparation of electrode inks with chitosan binder

The electrode inks were prepared using a non-toxic chitosan binder according to the methodology described in our previous study [4]. When dried, the ink consists of approximately 5.4% binder and 94.6% active material (by mass).

Preparation of symmetrical SCs by screen printing

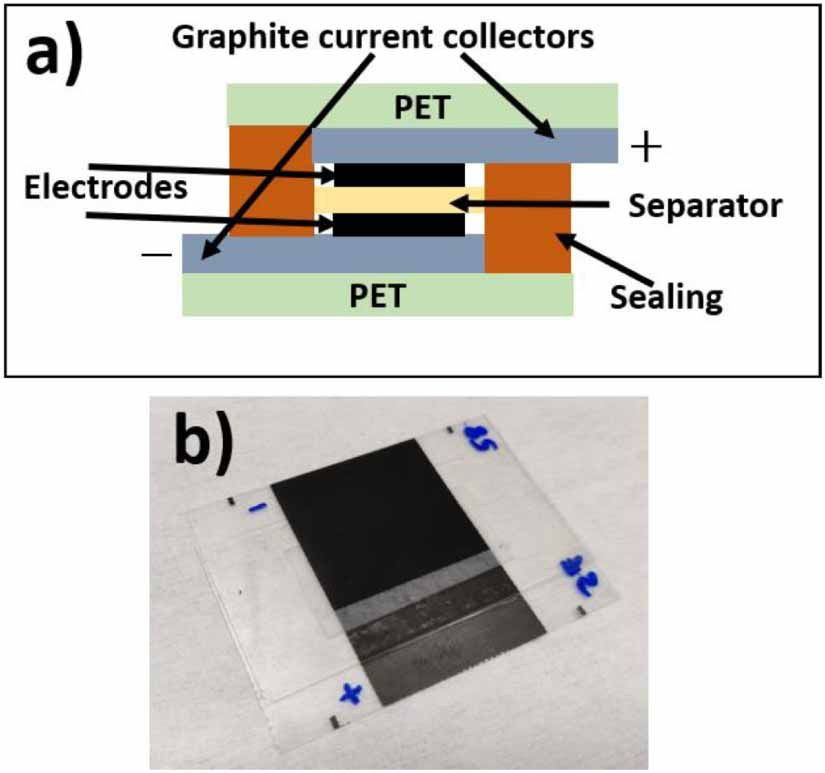

SCs were prepared by screen printing using PANI/CDC (10:1) and (30:1) variants. Samples were prepared by screen printing a graphite current collector and a PANI/CDC electrode onto two PET substrates forming the positive and negative halves of an SC. Screen printing was performed using a sheet-to-sheet printing process, with a screen mesh count of 24 cm-1 and a filament diameter of 125 μm.

The current collectors were printed with a commercial graphite ink (Acheson ELECTRODAG PF-407C). After printing, the current collectors were dried for 1 h at 95 °C. The dried current collectors were treated with nitrogen plasma for 30 min to improve the wettability of the PANI/CDC ink on the graphite surface.

Electrodes with a geometric area of 3 cm x 1 cm were then screen printed onto the current collectors with the PANI/CDC ink and then dried at 60 °C for 30 minutes. They were assembled in the same way as the squeegee-coated electrodes. The structure and the real image of the manufactured SC are shown in Fig. 1a and Fig. 1.b.

Fig. 1: (a) Schematic of a symmetrical supercapacitor with two electrodes, (b) photo of an assembled supercapacitor; image: study

Fig. 1: (a) Schematic of a symmetrical supercapacitor with two electrodes, (b) photo of an assembled supercapacitor; image: study

Conclusion

In this study, PANI/CDC hybrid composites were synthesized by in situ chemical oxidative polymerization of aniline in the presence of CDC. The morphology of the PANI/CDC composites shows that the PANI particles were successfully deposited on the carbon surface. Therefore, the electrical conductivity of the composite powder is dominated by the conductivity of PANI. Printable PANI/CDC ink materials based on chitosan binder in water and with 0.5 M Na2SO4 as electrolyte were developed, while pure PANI ink without CDC was not printable due to its fragile structure. The symmetrical SCs of PANI/CDC composites were successfully produced by both doctor blade coating and screen printing.

The electrochemical measurements were performed with both three and two electrodes. As a result of the combination of electrostatic charge accumulation and reversible redox processes at the interface between electrode and electrolyte, the PANI/CDC composites offered a significantly higher specific capacitance (up to 419 F g-1 at 1 Ag-1) than the original CDC electrode (144 F g-1 at 1 Ag-1). The capacitance of the screen-printed SCs was 440-470 mF with an ESR of about 27 Ω. This study demonstrates that it is possible to implement a screen-printing approach for the fabrication of electrodes with carbon-based polymer composite inks using a non-toxic chitosan binder. The results could pave the way for future sustainable and commercial energy storage applications of screen printable SCs.

References

[1] Li H and Liang J 2020 Recent development of printed micro-supercapacitors: printable materials, printing technologies, and perspectives Adv. Mater. 32, 1805864.

[2] Gao Y, Guo X, Qiu Z, Zhang G, Zhu R, Zhang Y and Pang H 2022 Printable electrode materials for supercapacitors ChemPhysMater 1, pp. 17-38.

[3] Zheng L, Wang Y, Wang X, Li N, An H, Chen H and Guo J 2010 The preparation and performance of calcium carbide-derived carbon/polyaniline composite electrode material for supercapacitors J. Power Sources 195, pp. 1747-52.

[4] Inci Yesilyurt E, Pionteck J, Simon F and Voit B 2023 Fabrication of PANI/MWCNT supercapacitors based on a chitosan binder and aqueous electrolyte for enhanced energy storage RSC Appl. Polym. 1, S. 97-110.

Note

The study was published as an open access paper at 'IOP Science' on December 7, 2023. The PLUS became aware of the study at LOPEC 2023 in Munich through a presentation by Ms. Ezgi Inci Yesilyurt. For the special issue of PLUS in February, Ms. Inci allowed the German translation of this abstract.

The study was published as an open access paper at 'IOP Science' on December 7, 2023. The PLUS became aware of the study at LOPEC 2023 in Munich through a presentation by Ms. Ezgi Inci Yesilyurt. For the special issue of PLUS in February, Ms. Inci allowed the German translation of this abstract.

The complete study, awarded the Creative Commons license CC BY 4.0 Deed, can be found at: 'IOP Publishing, Flexible and Printed Electronics, Volume 8, Number 4' - Online: https://iopscience.iop.org/article/10.1088/2058-8585/ad0ebd.- License link: https://creativecommons.org/Licenses/by/4.0/

The work received funding from the EU Horizon 2020 Research and Innovation Program for the project InComEss (Grant Agreement Number 862597).