Thin-film solar cells processed with the aid of picosecond lasers are 10 to 15 % more efficient than those conventionally structured by scribing. A working group at Munich University of Applied Sciences led by Prof. Dr. Heinz P. Huber has made this laser process industrially applicable and is now focusing its research on making it even more effective. The production use of the process to date has already saved 20 kt/a ofCO2 emissions - equivalent to the emissions caused by around 3000 people in Germany every year.

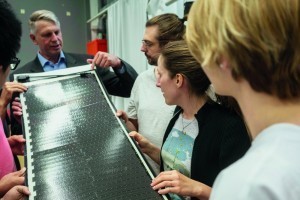

Fig. 2: Prof. Dr. Heinz P. Huber conducts research at the laser laboratory at Munich University of Applied Sciences into processes that save twenty thousand tons ofCO2 per year in the production of thin-film solar cells using picosecond lasersThin-filmsolar cells processed by picosecond lasers are 10 to 15 % more efficient than those conventionally structured by scribing. A research group at Munich University of Applied Sciences led by Prof. Dr. Heinz P. Huber has made this laser process industrially applicable and is now concentrating its research on making it even more effective. The production use of the process to date has already been able to save 20 kt/a ofCO2 emissions - equivalent to the emissions caused by around 3000 people in Germany every year.

Fig. 2: Prof. Dr. Heinz P. Huber conducts research at the laser laboratory at Munich University of Applied Sciences into processes that save twenty thousand tons ofCO2 per year in the production of thin-film solar cells using picosecond lasersThin-filmsolar cells processed by picosecond lasers are 10 to 15 % more efficient than those conventionally structured by scribing. A research group at Munich University of Applied Sciences led by Prof. Dr. Heinz P. Huber has made this laser process industrially applicable and is now concentrating its research on making it even more effective. The production use of the process to date has already been able to save 20 kt/a ofCO2 emissions - equivalent to the emissions caused by around 3000 people in Germany every year.

The amount of solar energy that can theoretically be used worldwide is around 100 times higher than that available from wind power and renewable raw materials. Solar energy is therefore also an essential part of the mix of renewable energies in the German energy transition. Although current silicon solar cells are cheap due to their mass production, their manufacturing process is more complex and less resource-efficient than thin-film cells. If the latter are also produced using the processing method developed by the Huber research group with the aid of a picosecond laser, they have an even higher efficiency of 10 to 15 %. Despite their currently still small market share, at 20,000 tons per year they already save theamount of CO2 that 3000 people in Germany emit on average each year.

Producing CIGS thin-film cells with picosecond lasers

So-called CIGS thin-film solar cells consist of layers measuring just a few micrometers. The light-absorbing layer made of the semiconductor copper indium gallium diselenide (Cu(In,Ga)Se2) gives them their name. In addition to the former material, copper indium disulphide (CuInS2) is also frequently used. The abbreviation CIGS is also used here.

The wafer-thin cells consist of a sandwich of four layers: the 3 mm glass substrate, a 1 µ molybdenum layer, the eponymous CIGS layer of 3 µ and a window layer of zinc oxide of another 1 µ.

To produce electricity, the large CIGS layer of the cell must have a structure of fine grooves that divide the CIGS surface into around one hundred individual cells. As with batteries that are connected in series, the voltage of a cell can be increased from around 1 V to around 100 V for the cell module. However, the molybdenum layer under the CIGS layer must not be damaged during this machining process.

The previous mechanical scribing of the grooves had disadvantages: "Wider grooves are created with the scribing needle, and poorly conductive residues remain at the bottom of the grooves. If you remove the layers with the picosecond laser, you can create finer lines that conduct the current better. The efficiency of the cell increases without significantly increasing costs," says Huber.

Graduates in demand

With around 500 professors, 750 lecturers and around 18,000 students, Munich University of Applied Sciences is one of the largest universities in Germany. It offers over 85 Bachelor's and Master's degree courses in the fields of engineering, business, social sciences and design. Excellently networked in the business location of Munich, it maintains close contacts with professional practice and is committed to application-oriented teaching and research. Munich University of Applied Sciences was recognized as a start-up university in EXIST III, IV and EXIST Potentials. In addition to specialist skills, it teaches its students entrepreneurial and sustainable thinking and action. Trained in interdisciplinary work and intercultural thinking, its graduates are prepared for a digitally and internationally networked working world. In rankings, they are among the most sought-after by employers throughout Germany.

Industrial production process for CIGS cells

Huber used laser pulses with a duration of picoseconds and a high repetition rate, thus making the industrial production of CIGS thin-film cells with the help of laser structuring possible in the first place: "With a nanosecond laser, you burn all three layers and melt them together. Only with the ultrashort pulse laser, such as the picosecond laser we use, can you structure the top CIGS layer without damaging the molybdenum layer underneath," says the researcher. The bond between the molybdenum and the transparent zinc oxide top layer is stronger. This also reduces internal energy losses, which increases efficiency.

By streamlining the manufacturing process, Huber sees further potential for improvement in the future in terms of efficiency and reducing production costs. The alternating layer application of the individual CIGS layers and structuring is to be merged into a joint application of all layers and their joint laser structuring.

Prof. Dr. Heinz P. Huber has been teaching and researching at Munich University of Applied Sciences as Professor of Laser Technology and Photonics since 2004. After studying technical physics at the Technical University of Munich, he completed his doctorate at the LMU Munich on the subject of 'Ultrafast spectroscopy of photosynthesis'. His research focuses on the application of ultrashort pulse lasers, in particular the use of lasers in photovoltaics to improve production methods, ultrashort pulse lasers as tools in production and fundamental investigations into the interaction of laser pulses with materials using ultrashort time-resolved experiments and simulations.

http://fk06.hm.edu/pol/en/forschungsfeld.html

Publications

J. Winter, S. Rapp, M. Spellauge, C. Eulenkamp, M. Schmidt, H. P. Huber, 'Ultrafast pump-probe ellipsometry and microscopy reveal the surface dynamics of femtosecond laser ablation of aluminum and stainless steel', Applied Surface Science 511 (2020) 145514, DOI: 10.1016/j.apsusc.2020.145514

F. Kessler, D. Hariskos, S. Spiering, H. P. Huber, E. Lotter, R. Wuerz, 'CIGS Thin Film Photovoltaic-Approaches and Challenges', in: High-Efficient Low-Cost Photovoltaics, January 2020, DOI: 10.1007/978-3-030-22864-4_9, Springer Series in Optical Sciences Vol. 140

P. Kubis, J. Winter, A. Gavrilova, M. Hennel, S. Schlosser, I. Richter, A. Distler, M. Heyder, S. Kery, P. Lenk, S. Geiger, C. J. Brabec, H. P. Huber and Hans-Joachim Egelhaaf 'All-sub-nanosecond laser monolithic interconnection of OPV modules' Progress in Photovoltaics: Research Application (2019) DOI:10.1002/pip.3115

Gerhard Heise, Andreas Börner, Marcel Dickmann, Marina Englmaier, Andreas Heiss, Matthias Kemnitzer, Jan Konrad, Regina Moser, Jörg Palm, Helmut Vogt and Heinz P. Huber, 'Demonstration of the monolithic interconnection on CIS solar cells by picosecond laser structuring on 30 by 30cm² modules', Progress in Photovoltaics: Research Application (2014) DOI: 10.1002/pip.2552