Complex optical elements for precision optics, lighting or displays are the main areas of application for transparent plastics. Here they are clearly superior to solutions made of glass.

Introduction

Transparent plastics became firmly established for optical applications at the end of the 20th century. They are lighter than glass and offer the possibility of cost-effective mass production in injection molding and embossing processes. Complicated shapes such as aspherical surfaces and the integration of mounting elements can be realized much more easily. Transparent thermoplastics such as polycarbonate are therefore used in particular for the production of complex optical elements in the fields of precision optics, lighting and displays. A prerequisite for optical applications is the availability of anti-reflective (AR) coatings for anti-glare surfaces. It is also important to provide the soft materials with a permanently high mechanical resistance through thin layers.

New highly refractive polymers

Poly-bisphenol-A-carbonate (PC, brand names e.g. Makrolon® and Lexan®) has long been established and is the most commonly used transparent polymer material with a relatively high refractive index. Highly refractive materials are needed, among other things, to correct chromatic aberration in lenses. As part of a research project funded by the IGF, several newer high refractive index polymers were investigated at the IOF in direct comparison with PC in order to highlight advantages and determine limitations for vacuum coating [1]. Figure 1 provides an overview of the chemical composition of the newer polymers in comparison to PC Makrolon®, as far as can be estimated from the manufacturer's specifications [2-4]. Both newer material groups, the EP polycarbonates from Mitsubishi Engineering-Plastics Corp. (including Iupizeta™ EP-6000 and EP-8000), and the OKP polyesters developed by Osaka Gas Chemicals (including OKP-1, OKP-4) also contain diphenyl fluorene groups, unlike PC.

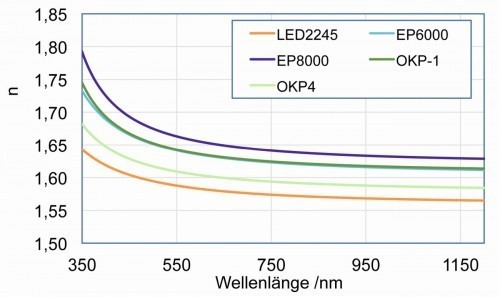

Fig. 2: Dispersion of the polymers investigated (refractive index as a function of wavelength)

Fig. 2: Dispersion of the polymers investigated (refractive index as a function of wavelength)

|

Properties of |

LED2245 |

EP-6000 |

EP-8000 |

OKP-1 |

OKP-4 |

|

Refractive index at 500 nm |

1,59 |

1,65 |

1,68 |

1,65 |

1,62 |

|

Abbezahl νd |

31 |

25 |

21 |

25 |

29 |

|

UV absorption edge [nm] |

316 |

339 |

385 |

383 |

337 |

|

Pencil hardness |

4B |

HB |

HB |

B |

B |

|

Water content 24h, DIN EN ISO 62 |

0,25% |

0,24% |

0,16% |

0,26% |

0,30% |

|

Water content, maximum |

0,42% |

0,56% |

0,43% |

0,60% |

0,75% |

|

Static contact angle H2O |

80° |

73° |

74° |

80° |

74° |

Some of the properties of the polymers that were determined during the comparative tests are summarized in Table 1. Some of the polymers in the EP and OKP series offer higher refractive indices than Makrolon (see Fig. 2). The higher hardness, especially of the EPs, should be emphasized. A disadvantage is the lower resistance of the optical properties to UV radiation [9].

Anti-reflective coating and hardening with AR-hard®

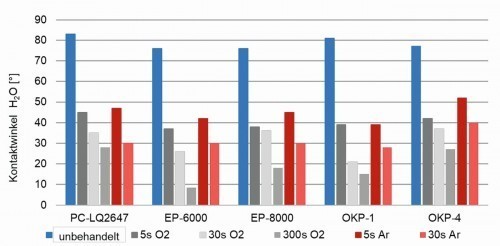

An essential part of the project was the investigation and evaluation of the behavior of the polymers in plasma coating processes. The ability to bond oxides firmly to the polymer surfaces is crucial for the production of stable optical coatings. A suitable process for producing coatings at low substrate temperatures is plasma ion-assisted deposition (plasma IAD) [5]. The experiments were carried out in an APS 904 system (Bühler Leybold-Optics). The layer-forming oxide materials are vaporized with the aid of an electron beam and condense on the polymer substrates attached to the rotating calotte. A bombardment of the growing layer with argon ions from a plasma ion source causes a layer densification and the adjustment of defined mechanical and optical properties. Plasma treatment prior to vapor deposition can activate the surfaces so that coating materials bond better. However, substrate damage can also be triggered, which later hinders an adhesive coating [6]. Figure 3 shows the contact angles measured after various plasma treatments, which are a measure of the hydrophilization of the surfaces.

Fig. 3: Contact angles before and after plasma activation using an APS ion source (80V bias, 2*10-4 mbar pressure). The contact angles were measured within 20 minutes after aeration of the system

Fig. 3: Contact angles before and after plasma activation using an APS ion source (80V bias, 2*10-4 mbar pressure). The contact angles were measured within 20 minutes after aeration of the system

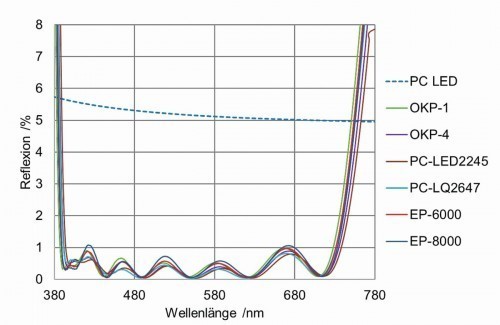

The AR-hard® design principle developed by Fraunhofer IOF forms the basis for the simultaneous realization of surface hardening and anti-reflective coating of plastics [7]. Such a coating system with a total thickness of 1.2 µm was adapted to the refractive index range of the high-index polymers for broadband antireflection coating in the visible spectral range (Fig. 4). Furthermore, the conditions for plasma activation of the polymer surfaces were investigated and the parameters for plasma pretreatment were set to the minimum time and energy required.

Fig. 4: Reflection of the AR-hard® anti-reflective polymers compared to the uncoated PC (all spectra without back reflection)

Fig. 4: Reflection of the AR-hard® anti-reflective polymers compared to the uncoated PC (all spectra without back reflection)

Excellent coating adhesion was achieved on the EP polymers and on OKP-1 with the systems and deposition parameters that were also optimal for PC [8]. On OKP-4, the adhesion results varied between very good and mediocre. The AR-hard® coating reduced the reflection in the visible spectral range from 5% to less than 0.5% and at the same time increased the abrasion resistance of the surfaces [9].

You can find out more about this and other joint industrial research projects at V2021 from October 12 - 14, 2021 in Dresden. The established conference with accompanying industrial exhibition on the topic of surface technologies and their applications presents, among other things, the workshop "Functional optical coatings and coating systems" as well as other events on vacuum technology, digitization, surface technology in practice and much more. Find out more and register now at www.efds.org/die-v/. Here you can get in touch with the right experts from the industry and find out about offers on the topic at the extensive industry exhibition.

Acknowledgement

The IGF project 20663 BR of the European Research Association for Thin Films (EFDS) is funded by the Federal Ministry for Economic Affairs and Energy (BMWI) via the AiF as part of the program for the promotion of joint industrial research and development (IGF). We would like to thank the EFDS for their kind support of the project work. Special thanks go to Tina Seifert and Caroline Hahmann, who made significant contributions to the results presented here as part of their student research projects. Responsibility for the content lies with the authors.

Literature

[1] IGF research project "Coating of novel polymers for optical applications" (Polymere2020); https://www.iof.fraunhofer.de/de/geschaeftsfelder/funktionale-oberflaechen-und-schichten/kunststoffoptiken/polymere-2020.html

[2] Manufacturer Information Makrolon, https://solutions.covestro.com/en

[3] Manufacturer Information EP, https://www.mgc.co.jp/eng/products/kc/iupizeta_ep.html

[4] Manufacturer Information OKP, https://www.ogc.co.jp/e/products/fluorene/okp.html

[5] S. Pongratz; A. Zöller: Plasma ion assisted deposition: A promising technique for optical coatings, J. Vac. Sci. Technol. A 10 (4), 1992, 1897-1904

[6] U. Schulz: Review of modern techniques to generate antireflective properties on thermoplastic polymers, Appl. Opt. 45, 2006, 1608-1618

[7] U. Schulz; U.B. Schallenberg; N. Kaiser: Antireflective coating design for plastic optics, Appl. Opt. 41, 2002, 3107-3110

[8] T. Seifert, Master's thesis, Ernst Abbe University of Applied Sciences Jena, January 2021

[9] U. Schulz et.al.: Coating-relevant properties of high-index optical polymers for automotive applications, Applied Optics 60 (20),2021, 1559