As part of a collaborative project, a plasma-based coating process was developed under ambient conditions for the targeted pre-treatment of fluoropolymers. Significant increases in adhesion were achieved on two tested adhesive composites. The adhesion-promoting plasma layers, which can also greatly improve wettability, offer great potential for numerous industrial applications.

Since the first successful synthesis of polytetrafluoroethylene (PTFE) in 1938 and with the continuous development of further fluoropolymers, this class of materials is now widely used in everyday life and in industry [1]. The reason for this is its many outstanding properties. For example, fluoropolymers are characterized by strong hydrophobicity and oleophobicity, high thermal and chemical resistance, excellent weather resistance, good sliding properties and a low dielectric constant [2]. The tendency to be resistant to almost all chemicals and also have a high biocompatibility makes special fluoropolymer materials interesting for medical applications. Examples include arterial catheters for blood collection, vascular implants or coatings on medical devices. The positive material properties of fluoropolymers are caused by C-F bonds, the strongest single bond in organic chemistry, combined with the high electronegativity of fluorine [3].

In addition to the undoubtedly positive properties of this class of materials, possible negative effects on the environment, food and drinking water have increasingly come into focus in recent years. Since March 2023, the European Chemicals Agency (ECHA) has been discussing a proposal to restrict the manufacture, marketing and use of per- and polyfluoroalkyl substances (PFAS) in the future. The most important point here is the high persistence of PFAS, i.e. their resistance to chemical-physical and biological degradation, as well as other factors such as possible bioaccumulation in living organisms [4]. To what extent and for which types of PFAS future regulation will be envisaged is the subject of ongoing debate involving industrial producers and users.

The further processing of fluoropolymers with subsequent bonding or printing processes represents a general challenge. Pretreatment processes available on the market are mostly based on chemical etching solutions or primers with sodium-naphthalene complexes as a basic component [5]. The most important effect of sodium etching is defluorination, whereby the fluorine atoms can be detached from the carbon skeleton of the polymer and functional groups can be formed. The chemicals used for this are often classified as hazardous or harmful to the environment and health. Pretreatment with plasma processes is another option for the functionalization of polymer surfaces to improve adhesion properties [6].

As part of the developments presented here, a plasma-based coating process was established under ambient conditions, which significantly improves the adhesion of adhesives and wettability on various fluoropolymer surfaces.

The implementation

The plasma tests were carried out on polytetrafluoroethylene (PTFE, Rocholl GmbH) flat substrates with dimensions of 20 mm × 10 mm × 2 mm or 40 mm × 40 mm × 2 mm, fluoroethylene-propylene (FEP, Saint-Gobain Performance Plastics Isofluor GmbH) tubing pieces with an outer diameter of 1.5 mm and cut to a length of approx. 35 mm, and cover glasses (Thermo Fisher Scientific Inc.) with dimensions of 35 mm × 9 mm × 0.1 mm. Prior to plasma treatment, the flat substrates were cleaned in isopropanol in an ultrasonic bath for 10 min. No additional cleaning step was carried out on the FEP tubing pieces.

As part of the developments, the focus was on the use of atmospheric pressure plasmas to improve the adhesion properties of the two fluoropolymers. At the heart of the plasma process is the commercially available T-JET plasma system from TIGRES GmbH [7]. In this system, a corona discharge is generated inside the head between two electrodes and directed onto the workpiece to be treated or coated by an air stream. The electrical power is 400 W and the width of the linear plasma generated in this way is approx. 45 mm. In order to deposit plasma-based thin films (so-called APPCVD - atmospheric pressure plasma enhanced chemical vapor deposition) in addition to plasma activation of the surfaces, the plasma system was supplemented by a specially developed precursor dosing nozzle (Fig. 1 left). This consists of two slotted nozzles, each with an outlet opening 40 mm wide, which enables the chemical precursor to be introduced evenly into the plasma from two sides. The precursor used is 3-aminopropyltriethoxysilane (APTES, Sigma-Aldrich Chemie GmbH) in its undiluted state, which was introduced into the plasma via an evaporator with air as the carrier gas and converted by the plasma interaction to form layers on the substrate surfaces. The substrates were moved under the stationary plasma system using a machine, whereby the flat substrates (PTFE, glass) were held on an x-y table and the FEP tubing pieces with the aid of a rotary holder (Fig. 1 right). The plasma electrode-substrate distance was 20 mm in each case.

The resulting thickness of the functional plasma layer can be controlled by varying the APTES precursor flow rate, the traversing speed and the number of coating passes / coating time. Table 1 summarizes the varied process parameters.

The following methods were used for an analytical assessment of the surface and coating properties. The surface roughness according to DIN EN ISO 25178 was determined using confocal microscopy measurements (MarSurf CM explorer, MAHR GmbH) on PTFE. The PTFE exhibited two different surface conditions during the investigations carried out here. On the one hand, the surface quality of the substrates provided by the manufacturer was used. On the other hand, a defined roughening was carried out by means of corundum blasting (Al2O3 grain size: 130 µm). Furthermore, water contact angle measurements (OCA15+, DataPhysics Instruments GmbH) were carried out on PTFE samples to assess the wetting behavior as well as analyses of the surface composition using X-ray photoelectron spectroscopy - XPS (Axis Ultra DLD, Kratos Analytical Ltd.). Due to the very smooth surface of glass, this substrate material was also used to analyze the layer thickness of the APTES plasma layers using tactile profilometry (Alpha-Step D-600, KLA Tencor Corp.) and the layer morphology using scanning electron microscopy (SEM Zeiss Supra 55 VP, Carl Zeiss AG).

The primary aim of these developments is to improve the bondability of the fluoropolymers. Accordingly, adhesion tests were carried out on both polymer types, which are briefly described below. The PTFE substrates were bonded directly to the end faces with steel punches (Ø5 mm, length: 5 mm) using a 2-component epoxy resin-based construction adhesive (Scotch-Weld DP460, 3M). The adhesive bond was oven-cured at 65 °C for 2 hours. In the subsequent compression shear test (testing machine: Inspekt table 50 kN, Hegewald & Peschke), the stamp was sheared downwards from the PTFE surface and the resulting shear strength was determined on 5 composite samples in each case. For the FEP tubing, a design similar to that used, for example, for arterial catheters in human medicine was selected. Here, the outside of the tube is bonded to the inside of a connector whose diameters are matched to each other. The connector used was an injection-molded part made of ABS from ALPO Medizintechnik GmbH, and the adhesive was a cyanoacrylate (Loctite 4061, Henkel) that meets the medical requirements for biocompatibility of DIN EN ISO 10993. The adhesive bond was cured at room temperature over a curing time of at least 30 minutes. Sterilizability is an essential criterion in the field of application of medical products. In this respect, some of the bonded components were also subjected to steam sterilization, which also served as a stress test for the bond. The autoclave Systec VX-55 (Systec GmbH & Co. KG) with a predefined sterilization program was used, whereby the maximum load corresponded to a pressure of 2 bar and a temperature of 134 °C, with a holding time of 10 minutes. The subsequent tensile shear tests (4-fold determination) were carried out with the aforementioned testing machine and in accordance with DIN EN ISO 10555-1. The maximum tensile force Fmax is evaluated, whereby a minimum tensile force of 10 N is required for hose outer diameters in the range 1.15-1.85 mm.

Improved properties through the use of plasma technology

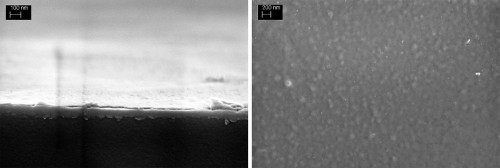

APTES-based thin films could be generated on all three substrate types using the plasma coating process developed. The profilometric analyses on glass show that, depending on the plasma parameters (Table 1), layer thicknesses between < 5 and approx. 200 nm could be generated. In addition, the coatings show only slight changes in coating thickness after 10 minutes of water storage or interaction with ethanol (possible solvent of the APTES precursor) in the ultrasonic bath and therefore exhibit good resistance. Figure 2 shows an example SEM image of an approx. 100 nm thick plasma layer on glass using APTES as a precursor.

|

Plasma parameters |

Flat substrates (PTFE, glass) |

FEP tube |

||

|

Plasma |

Plasma |

plasma |

plasma |

|

|

Precursor |

- |

APTES |

- |

APTES |

|

Precursor flow rate |

- |

50-400 µl/min |

- |

50 µl/min |

|

Velocity - 25 mm/s |

25 mm/s |

50-500 mm/s |

2 rpm |

2 rpm |

|

Number of passes (DL) or time |

1-8 DL |

2-20 DL |

1-10 s |

1-10 s |

The images of the SEM fracture edge show that the deposited thin film is compact and closed. The film surface appears predominantly smooth. Individual agglomerates and fine particles up to approx. 200 nm in diameter are also formed and deposited on the substrate.

Fig. 2: SEM of a plasma-coated glass sample with APTES as precursor; fracture edge (left) and top view (right)

Fig. 2: SEM of a plasma-coated glass sample with APTES as precursor; fracture edge (left) and top view (right)

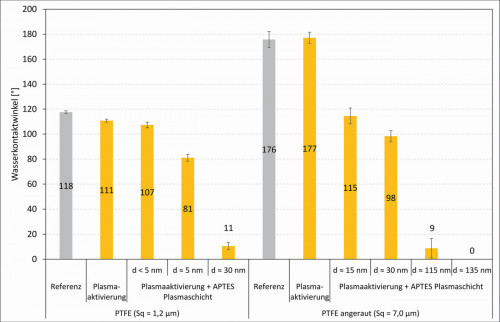

A look at the wetting behavior of the PTFE substrates (Fig. 3) shows that the water contact angle increases from 118° to 176° due to mechanical roughening. The corresponding surface roughness value Sq increases from 1.2 µm to 7.0 µm after corundum blasting. The effect of reducing wetting on non-polar plastics such as PTFE through blasting processes is known from the literature and can be used to create superhydrophobic surfaces [8]. Pure plasma activation with the T-JET plasma system and air as the process gas did not result in any significant changes in the wetting properties. An additional plasma coating, on the other hand, allows the wetting of the surface to be controlled, from hydrophobic behavior to superhydrophilic surface properties. For both surface states of the PTFE substrates, the water contact angles tend to decrease with increasing coating thickness. For APTES layer thicknesses (determined on glass) from approx. 30 nm on PTFE and approx. 115 nm on roughened PTFE, contact angles of ≤ 10° were achieved. Additional XPS analyses on the coated PTFE substrates show that almost no fluorine (< 1 at.%) of the base substrate can be detected with plasma layers of approx. 30 nm thickness. Accordingly, the

APTES-based plasma layers in this layer thickness range appear to be homogeneous and closed on the non-roughened PTFE substrates.

Fig. 3: Water contact angle measurements on PTFE substrates and PTFE substrates roughened by corundum blasting; comparison of the reference material with plasma-activated or plasma-coated substrates (variation in layer thickness)

Fig. 3: Water contact angle measurements on PTFE substrates and PTFE substrates roughened by corundum blasting; comparison of the reference material with plasma-activated or plasma-coated substrates (variation in layer thickness)

In the XPS, the elements oxygen, carbon, silicon and nitrogen can be detected in the plasma layers, sorted by decreasing concentration. The maximum nitrogen content is approx. 13-14 at.%. By evaluating the detailed spectra of the nitrogen N 1s signal, statements can be made about the presence of functional or adhesion-promoting groups. Overall, the analyzed detail spectra indicate that a total of three functional chemical groups are present in the layers, two of which can be assigned to amino groups (NH2) and nitrates (NO3-) using database values. The proportion of amino groups in the nitrogen signal is between 30-65 %, depending on the plasma parameters. During the plasma coating process with air as plasma gas, an oxidation of the amino groups of the APTES precursor thus takes place to some extent, which consequently also corresponds to an increase in the wetting behavior.

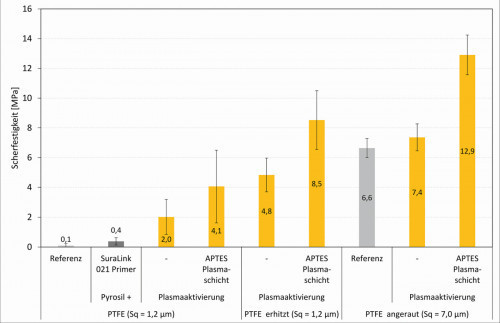

The influence of the plasma pre-treatment on the fluoropolymer samples on the resulting adhesion properties of the adhesive composites produced was investigated as a key criterion. Figure 4 initially shows the shear strengths for the PTFE / steel stamp composite system using the DP460 adhesive. In addition to the untreated PTFE ("reference"), a primer pre-treatment of the PTFE surface was also considered as an additional reference. In this type of pre-treatment, a functionalization with a silicate Pyrosil layer was first carried out as an adhesive primer with subsequent spray application of the commercially available primer SuraLink 021 (Sura Instruments GmbH), which can be used for epoxy resin bonding, among other things [9]. This type of pre-treatment is established on the market for a variety of plastics and other material classes such as glass, metal and ceramics.

Fig. 4: Pressure shear test on PTFE / steel composite samples, adhesive DP460, comparison of different pre-treatments of the PTFE substrates

Fig. 4: Pressure shear test on PTFE / steel composite samples, adhesive DP460, comparison of different pre-treatments of the PTFE substrates

At 0.1 MPa, there is almost no shear strength on untreated PTFE samples and even with the combination of Pyrosil & primer, the adhesion can only be increased slightly. Overall, a significant improvement can be achieved by using the developed plasma processes, whereby the combination of plasma activation and APTES plasma coating provides better adhesion properties than pure plasma activation in all cases considered. On non-roughened PTFE samples (Sq = 1.2 µm), the shear strengths after plasma coating are approx. 4 MPa. By additionally heating the PTFE substrates during the plasma treatment or coating, shear values of approx. 9 MPa can be achieved. A heating plate was used to heat the plastic surface to approx. 180 °C (measurement with a type K thermocouple). Such increases in adhesion to PTFE using elevated substrate temperatures have also been observed by other research groups. The property of PTFE to form a weak boundary layer (WBL) on the substrate surface is used as an explanation. According to Seto et al., the thickness of this boundary layer is in the order of 1 µm [10]. A combination of increased substrate temperature and plasma interaction can initiate increased etching processes (plasma etching) at the boundary layer and remove it partially or completely, which is accompanied by a significant increase in the adhesion of adhesives [11]. If the PTFE surface is roughened (Sq = 7.0 µm), the adhesion of the adhesive already increases significantly on the untreated reference material. Although the surfaces have superhydrophobic properties, the roughening leads to better mechanical anchoring of the adhesive, presumably also supported by the removal of the WBL during the blasting process. The plasma coating significantly increased the adhesion of the epoxy resin once again, from approx. 7 MPa to approx. 13 MPa. Adhesive failure between the PTFE surface and the adhesive occurred on all samples.

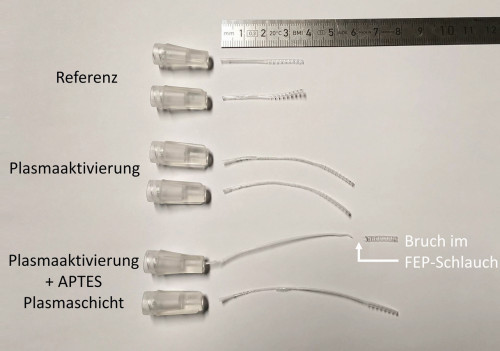

Adhesion was also significantly improved on the FEP tube / ABS connector composite system. In this case, both components were bonded together with a cyanoacrylate adhesive after plasma pre-treatment of the outside of the FEP tube. Figure 5 shows two exemplary samples after the tensile shear test for each of the tested surface conditions of the FEP hose material.

On the untreated reference samples, adhesive failure of the FEP tubing occurs immediately after the start of the tensile load, without necking or plastic deformation of the tubing. In the case of the plasma treatments carried out, the fracture of the bond only occurs after a previous necking or stretching of the hose material. Adhesive fractures also occur primarily between the FEP tube and the adhesive in these samples. If the combination of plasma activation and APTES plasma coating is used, fractures within the tubing material are also increasingly observed. The elongation ε is typically > 140 %.

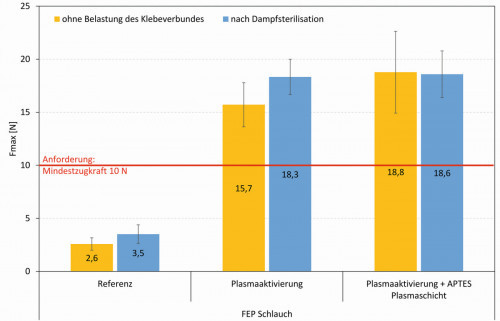

Correspondingly, Figure 6 shows the measured maximum tensile forces Fmax for the composite samples produced, both without and with additional loading of the bond by means of steam sterilization.

Only by pretreating the FEP tube surface can the tensile force of 10 N required by DIN EN ISO 10555-1 be achieved and reproducibly exceeded. Both processes, pure plasma activation with air as plasma gas and the combination with additional APTES plasma coating, can be used for this purpose. The maximum tensile force can be increased from approx. 3 N in the references to approx. 16-19 N. To better classify these values, the inherent strength of the FEP hose material was also tested. Maximum tensile forces in the range of 17.9 ± 2.3 N were determined, i.e. a similar order of magnitude to the bonded composite samples, taking into account the plasma processes. The additional load tests carried out using steam sterilization led to comparable adhesion properties as before. The composite samples can therefore be sterilized. It should be noted that due to the high temperature of 134 °C during the sterilization process, the ABS connectors were heated above the glass transition temperature and slightly thermally deformed. In the next development steps, it is therefore planned to look at other sterilization methods, e.g. based on ethylene oxide or beta / gamma irradiation.

Application possibilities of the plasma coating

With the generation of adhesion-promoting plasma layers, which also greatly improve the wettability of fluoropolymers such as PTFE or FEP, a further process is available for the pre-treatment of these types of polymers. The processes developed can be used under ambient conditions and greatly reduce the use of environmentally hazardous chemicals for plastics pre-treatment. The investigations have shown that one and the same coating process is suitable for different joining partners and adhesive types. Shear strengths of up to approx. 13 MPa were achieved on PTFE / steel substrates bonded together using a 2-component epoxy resin construction adhesive. The focus here is on structural bonding as an application option. A composite of FEP tube / ABS connector, for future use in medical technology, was created by bonding with a certified cyanoacrylate adhesive. Thanks to the developed APPCVD coating process, as well as optimized plasma activation, the adhesion properties required by the standard were met and reproducibly exceeded.

Based on the research results to date, it can be assumed that this technology could also be used for other typical areas of application for fluoropolymers or fluorinated surfaces in the future. Examples include the bonding, printing or lamination of textiles, for the development of waterproof clothing or easy-to-clean surfaces in vehicle interiors. Another field of application could be the site-selective functionalization of films (e.g. ETFE), which are used in the construction of greenhouses or in the field of modern building architecture in general.

In addition to the fluoropolymers under consideration, the APPCVD coating process is generally applicable to dielectric surfaces such as glass, ceramics, wood or other types of plastic. In parallel research work, synergies were found, for example, in improved paint adhesion on resin-rich woods or powder coating adhesion on flat glass [12, 13]. Overall, the coating process developed offers a wide range of application possibilities in industry.

Acknowledgements

The authors would like to thank Martina Goetjes, Dr. Martina Schweder, Thomas Seemann, Jun Xu, Kathrin Höse, Dr. Svea Sachse and Dr. Hanen Ferjani. The work was supported by the Federal Ministry of Economics and Climate Protection (BMWK).

Literature

[1] H. Teng: Overview of the Development of the Fluoropolymer Industry, Applied Sciences, 2, 2, (2012), 496-512

[2] B. Ameduri: Fluoropolymers: The Right Material for the Right Applications, Chemistry - A European Journal, 24, 71, (2018), 18830-18841

[3] J. Lv et al: Fluoropolymers in biomedical applications: state-of-the-art and future perspectives, Chemical Society Reviews, 50, 5435, (2021)

[4] European Chemicals Agency - ECHA, Per- and polyfluoroalkyl substances (PFAS) Restriction Report, Version 2, 22.03.2023

[5] D. M. Brewis et al: Adhesion Studies of Fluoropolymers, The Journal of Adhesion, 41, 1-4, (1993), 113-128

[6] A. Heft et al.: Improvement of adhesion properties in bonding of fluoropolymers, 9th New Dresden Vacuum Technology Colloquium - NDVaK, Dresden, 18-19.10.2001

[7] T-JET Plasma from the company TIGRES GmbH; https://tigres-plasma.de/produkte/plasmasysteme/t-jet-technologie/, last accessed on 12.10.2023

[8] N. Menga et al.: Soft blasting of fluorinated polymers: The easy way to superhydrophobicity, Materials & Design, 121, (2017), 414-420

[9] SuraLink 021 primer from Sura Instruments GmbH; https://www.sura-instruments.de/produkte/zubehoer/primer-suralinkr; last accessed on 12.10.2023

[10] Y. Seto et al.: Cross-sectional observation of a weak boundary layer in polytetrafluoroethylene (PTFE) using scanning electron microscope, Polymer Journal, 54, (2022), 79-81

[11] Y. Ohkubo et al: Drastic Improvement in Adhesion Property of Polytetrafluoroethylene (PTFE) via Heat-Assisted Plasma Treatment Using a Heater, Scientific Reports, 7, 9476, (2017)

[12] S. Gerullis et al: Adhesion improvement of top coats on resin-rich woods by using functional plasma layers, submitted for publication in the journal Holztechnologie

[13] N. Fritzlar: Amino-functionalized coatings for adhesion improvement, 42nd Anwenderkreis Atmosphärendruckplasma - ak-adp, Naumburg, 9-10.11.2022