Modern plasma-assisted PVD technologies in mechanical engineering and component construction

Modern PVD and CVD technologies are ideally suited to the production of thin-film systems for the functionalization of component surfaces in the field of mechanical engineering and component construction. These, typically plasma and/or ion-assisted vacuum coating processes are convincing technologies for the realization of economical and reliable tribological systems, especially for the application area of mechanical engineering, tool and component coating, as they can be reproduced in high quality and are scalable and automatable for series production. Functional wear protection coatings create constructive freedom and new possibilities in component design. The base material provides the necessary strength and toughness of the component, while the coating protects against wear and corrosion and reduces friction. Metal-nitride, metal-oxynitride and metal-boride coatings are mainly used, but carbon coatings, known as DLC coatings (diamond-like carbon), are also proving their worth in numerous applications.

Modern plasma-assisted PVD processes

The decisive criteria for the performance and service life of mechanical engineering components and precision parts are their tribological properties, such as wear resistance, surface hardness and friction behavior. These functional surface properties can be applied to the component surfaces in the form of thin layer systems using modern, plasma-assisted PVD and CVD technologies. PVD stands for Physical Vapor Deposition with the basic processes of evaporation, magnetron sputtering and arc deposition, in which the layer is formed from the physical gas phase. CVD stands for chemical vapor deposition, in which the layer is formed from a chemically reactive gas phase. Both PVD and CVD process technologies are usually plasma-assisted in order to increase the energy of the layer-forming particles and keep the process temperatures low.

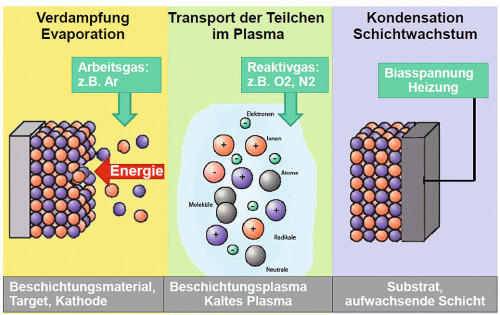

Fig. 1: Process principle of PVD technologies - characterized by three process phases: Generation of the coating material - Transport and reaction in the gas phase - Condensation on the substrate

Fig. 1: Process principle of PVD technologies - characterized by three process phases: Generation of the coating material - Transport and reaction in the gas phase - Condensation on the substrate

Improving mechanical properties

The starting material for the coating, the so-called target, is usually available in solid form. By applying energy (temperature, impulse, arc) to the target, the coating material is converted into the gas phase in the form of atoms, molecules and ions. In addition to the components of the starting material, the components of the working and reactive gases (e.g. Ar, O2, N2) also occur in the gas phase. In modern process technologies, the particles in the gas phase are additionally ionized by a plasma, so that higher-energy particles are available during layer formation on the substrate. The degree of ionization, the ion current density and the energy distribution of the layer-forming particles on the substrate are the key parameters of the coating process (Fig. 1). By applying a negative electrical voltage (bias) to the substrate, the positively ionized coating particles are accelerated from the gas phase to the substrate and impact there with increased kinetic energy. This leads to a densification of the growing layer and consequently to improved mechanical layer properties. The average kinetic energy of the particles depends on the average free path length (depending on the process pressure), the plasma parameters such as the degree of ionization, the distance between the target and the substrate and the applied bias voltage.

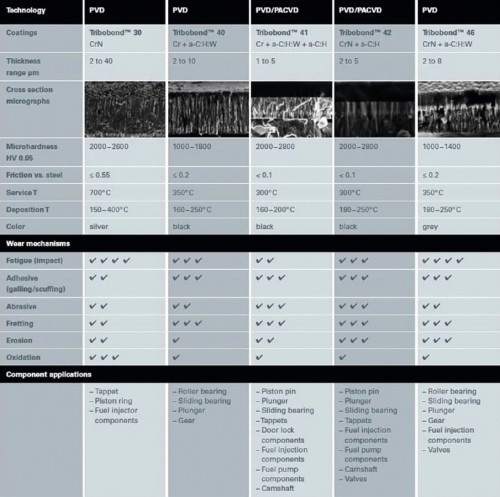

![Abb. 3: Einige Basisdaten zu den funktionellen PVD-Schichtsystemen im Anwendungsfeld Tribologie und Verschleißschutz [5] Abb. 3: Einige Basisdaten zu den funktionellen PVD-Schichtsystemen im Anwendungsfeld Tribologie und Verschleißschutz [5]](/images/stories/Abo-2022-03/thumbnails/thumb_gt-2022-03-0053.jpg) Fig. 3: Some basic data on functional PVD coating systems in the field of tribology and wear protection [5]

Fig. 3: Some basic data on functional PVD coating systems in the field of tribology and wear protection [5]

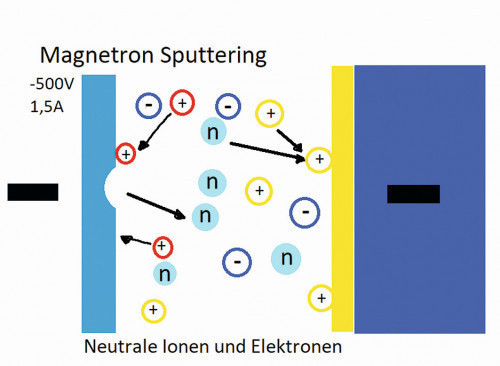

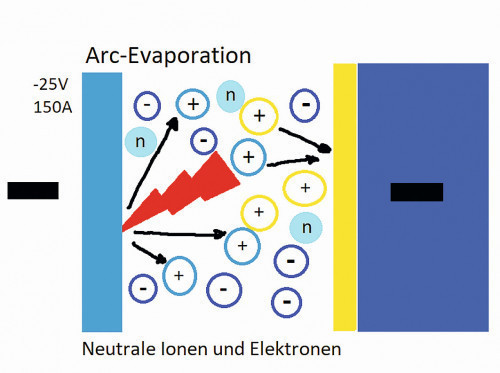

Magnetron sputtering, arc deposition, PACVD (plasma assisted CVD) and hybrid technologies are mainly used in mechanical engineering applications (see Fig. 2). By applying an electrical voltage to the target at a typical PVD process pressure of 10-4 mbar to 10-2 mbar, an electrical field is created which ignites a plasma above the target and generates positively charged ions through ionization. Ions, neutral and free electrons are thus present in the gas phase. Left: Magnetron sputtering - bombardment of the target surface with Ar+ ions (high voltage, low current, degree of ionization of the layer-forming particles 10-20 %). Right: Arc evaporation - ignition of a short-circuit arc on the target surface (low voltage, high current, degree of ionization of the layer-forming particles up to 100 %).

Plasma-assisted coating processes, such as magnetron sputtering and arc deposition, are proving to be convincing technologies for the realization of economical and reliable tribological systems, especially for mechanical engineering, tool and component coating applications, as they can be reproduced in high quality and are scalable and automatable for series production.

Experience shows that many surface functionality requirements can be met and optimized by the right choice of coating system. The various coating systems (e.g. metal nitrides, metal carbides and metal oxynitrides) can be used in a targeted manner according to their properties in order to achieve the desired results on the component surface. The coatings thus increase the performance, reliability and service life of components and enable a more compact and lighter design thanks to their surface properties. Further advantages are the reduced use of energy and operating resources, especially in the application fields of mechanical engineering and component construction, apparatus engineering, forming technology, as well as in engine and vehicle construction (Fig. 3).

Wear mechanisms

![Abb.4: Typische Verschleißmechanismen [2–4] Abb.4: Typische Verschleißmechanismen [2–4]](/images/stories/Abo-2022-03/thumbnails/thumb_gt-2022-03-0054.jpg) Fig.4: Typical wear mechanisms [2-4]The term "wear" is defined as a progressive loss of material from the surface of a body caused by mechanical causes, i.e. contact and frictional movement of a solid, liquid or gaseous counter-body [1].

Fig.4: Typical wear mechanisms [2-4]The term "wear" is defined as a progressive loss of material from the surface of a body caused by mechanical causes, i.e. contact and frictional movement of a solid, liquid or gaseous counter-body [1].

The function and production of mechanical engineering elements require materials that have to meet a wide range of requirements. The base material is often subject to different requirements and functionalities than the surface of the component. The design of the component is primarily characterized by the mechanical and thermo-mechanical loads, while the tribological loads in particular must be taken into account for the surface properties. The material engineering processes in the base body and on the surface are influenced and determined by numerous parameters, so that a tribological system for mechanical engineering applications can be characterized by the following functions [3]:

- Transmission of motion: e.g. for guides, joints, bearings

- Inhibition of movement: e.g. for brakes

- Power transmission: e.g. for clutches

- Energy transmission: e.g. in gearboxes

- Primary forming: e.g. for casting, pressing and extrusion tools

- Forming: e.g. for bending, rolling, forging and drawing tools.

In the various applications of mechanical engineering components, therefore, very different wear mechanisms occur, such as abrasive wear (joining, gouging), adhesive wear (seizure), surface fatigue (pitting), plastic deformation (running-in) and tribo-chemical wear (oxidation, corrosion) [2-4]. In practice, several of these mechanisms usually act simultaneously or occur one after the other during the wear process.

The identification of the dominant or relevant wear mechanisms in tribological systems provides initial information on which measures can reduce wear, e.g:

- Increasing the surface hardness

- Reduction of the coefficient of friction or friction coefficients

- Reduction of surface oxidation

- Passivation of the base material (Fig. 4).

Abrasive wear

Abrasive wear is the removal of material from the component surface due to hard, angular particles or friction partners (e.g. roughness peaks of the mating bodies). Abrasion is generally favored if the friction partners have very different surface hardnesses. This results in surface damage such as scratches, grooves, chips and abrasion on the friction partner with a lower surface hardness (hard-soft pairings can also be used specifically to prevent abrasion on the "hard" partner).

Adhesive wear

Adhesive wear mainly occurs when two rubbing surfaces form a close, adhesive bond under mixed friction conditions or during dry running, e.g. if the surfaces of the friction partners have a similar material composition or a high connection tendency. The result of adhesive wear is cold welding, smearing or destruction of the surface structure (galling).

Surface fatigue

Surface fatigue is caused by recurring mechanical or hydraulic swelling or alternating loads. The hardness and elasticity of the material are particularly important here. In the event of friction, wear can be reduced by lowering the coefficient of friction. The consequences of surface fatigue are cracks, holes, pits and deformations (pitting or micropitting).

Tribo-chemical wear

If the tribological frictional contact is accompanied by a chemical reaction, the reaction products influence the tribological processes on the surfaces. Tribo-chemical wear can be reduced by lowering the temperature and friction coefficient as well as inert (inert) contact surfaces and more dimensionally stable surfaces.

Surface functionalization through coating with thin layers

Surface functionalization by coating the component surface with thin layer systems provides a number of advantages that lead to a reduction in wear mechanisms and can therefore be used in the technological application of the components [3-5]:

- Use of more cost-effective base materials

- Ease of maintenance or reduction in maintenance costs

- Extension of the service life

- Improvement of load reserves

- Protection of the environment and resources by eliminating lubricants

- Good response behavior of moving systems

- Reduction of energy consumption in the use of components

- Enabling new component designs

- Construction with tight tolerances

Functional wear protection coatings applied using PVD (Physical Vapor Deposition) or PACVD (Plasma Assisted Chemical Vapor Deposition) processes create design freedom and new possibilities in component design. The base material provides the necessary strength and toughness of the component, while the coating protects against wear and corrosion and reduces friction.

Metal-nitride, metal-oxynitride and metal-boride coatings are mainly used, but carbon coatings, so-called DLC coatings (Diamond Like Carbon), have also proven themselves for numerous applications [4, 5]. The functional wear protection coatings provide outstanding properties that are essential for the use of mechanical engineering components:

- Very good adhesion to the base body

- High resistance to wear

- High surface hardness

- Low friction coefficients or coefficients of friction - coefficient of friction and wear, including the friction partners, are key properties of the entire tribological system

- Layer thicknesses typically in the mm range (0.5 to 10 mm)

- Improved corrosion resistance

- High reproducibility and contour accuracy.

Depending on the requirements and load criteria of specific applications, the coating consists of an adhesive layer, additional support layers and a functional top layer. The coating structure, the choice of materials and the thickness of the individual layers are always optimized for function and cost-effectiveness.

Application example: DLC coatings in the automobile

Fig. 5: Example: Typical tribological coating systems for wear protection and friction reduction in automotive applications [

Fig. 5: Example: Typical tribological coating systems for wear protection and friction reduction in automotive applications [

Specially developed for tribologically highly stressed systems, the application of DLC coatings enables new solutions in engines, injection systems and other units. DLC coatings drastically increase the efficiency of systems and the service life of components. Assembly costs can be kept at the same level as with conventional designs or even reduced, as simpler mechanical solutions with fewer components are often possible. The improved tribological properties of the coatings not only provide protection against wear, but also polish and protect the mating surfaces during running-in.

The result is a system with less friction and less wear(see Fig. 5: Tribobond™ 40). CrN has an exceptional combination of properties: high hardness, excellent toughness and high resistance to frictional wear and abrasion caused by shocks and impacts. CrN coatings can withstand temperatures of up to 700 °C, which makes the coating an ideal candidate for high-temperature applications. CrN has a much lower residual stress than many other coatings, which allows the deposition of thicker layers and is often used as an environmentally friendly replacement for electroplated hard chrome plating. The coating can also be applied directly to the finished components and does not require grinding back to the target dimensions. CrN protects against oxidation, scuffing and fretting wear. It has a low coefficient of friction against steel and good abrasion resistance (see Fig. 5: Tribobond™ 30) (Fig. 6).

Application example: PVD coatings for decorative applications

Decorative PVD coatings give designer surfaces a very special look. Attractive colors with a metallic character in combination with protection against signs of wear increase the value and service life of numerous products. PVD coatings in different compositions (TiN, TiAlN, CrN, CrON, DLC) and produced with different process parameters also offer a wider range of colors compared to classic galvanic processes and thus expand the range of applications in many areas. The coloring, which is independent of the base material, allows a uniform appearance even for components that are composed of several parts (see Fig. 7).

Application example: TiN coatings for medical applications

TiN is highly wear-resistant, stress-free, highly adhesive and forms an excellent chemical barrier layer. This makes TiN the ideal coating for medical instruments and implants. The biocompatibility is based on the ceramic character of the TiN bond and the strong bonding forces between titanium and nitrogen. TiN can be applied at temperatures between 150 and 500 °C. The wide temperature range makes it possible to coat various materials by adjusting the process temperature without damaging the geometries of the substrate(see Fig. 8, Medthin 01).

Literature

[1] GfT worksheet 7, Gesellschaft für Tribologie e.V., Aachen, Wear of metallic materials, Springer-Vieweg Verlag, 2002

[2] H. Czichos; K.-H. Habig: Tribologie-Handbuch Reibung und Verschleiß, 3rd edition, Vieweg-Verlag, 2010

[3] K. Bobzin: Surface technology for mechanical engineering, Wiley-VCG Verlag, 2013

[4] Ionbond Kapfenberg GmbH, IHI Group, www.ionbond.com/de/ueber-ionbond/ionbond-standorte/austria/

![Abb. 6: Beispiele für Schichtsysteme im Motorbau [5] Abb. 6: Beispiele für Schichtsysteme im Motorbau [5]](/images/stories/Abo-2022-03/thumbnails/thumb_gt-2022-03-0056.jpg)

![Abb. 7: Beispiel für funktionelle Schichtsysteme im Anwendungsbereich dekorative Verschleißschutzschichten [5] Abb. 7: Beispiel für funktionelle Schichtsysteme im Anwendungsbereich dekorative Verschleißschutzschichten [5]](/images/stories/Abo-2022-03/thumbnails/thumb_gt-2022-03-0057.jpg)

![Abb. 8: Beispiele für funktionelle Schichtsysteme für medizinische Anwendungen [5] Abb. 8: Beispiele für funktionelle Schichtsysteme für medizinische Anwendungen [5]](/images/stories/Abo-2022-03/thumbnails/thumb_gt-2022-03-0058.jpg)