The VDI has published a new status report entitled 'Machine learning - artificial intelligence with neural networks in optical measurement and inspection systems'. With this report, the engineers' association aims to introduce machine learning for optical measurement and inspection systems and present the potential of machine learning.

Machine vision (machine vision) in Germany can look back on decades of growth with a recent turnover of €2.8 billion in 2018. There is an increasing need in industry to automatically evaluate the image data generated, whether for process and quality control or in medical diagnostics. The electronics industry is also faced with the task of preparing for the introduction of AI, as image processing with object recognition and analysis is playing an increasingly important role in production.

What is machine learning?

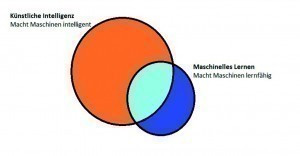

Fig. 1: Relationship between artificial intelligence and machine learningMachinelearning is a generic term for the 'artificial' generation of knowledge from experience: an artificial system learns from examples and can generalize these after the learning phase is complete(Fig. 1). To do this, machine learning algorithms build a statistical model based on training data. This means that the examples are not simply learned by heart, but patterns and regularities are recognized in the learning data. This means that the system can also evaluate unknown data (learning transfer) or fail to learn unknown data (overfitting) [1].

Fig. 1: Relationship between artificial intelligence and machine learningMachinelearning is a generic term for the 'artificial' generation of knowledge from experience: an artificial system learns from examples and can generalize these after the learning phase is complete(Fig. 1). To do this, machine learning algorithms build a statistical model based on training data. This means that the examples are not simply learned by heart, but patterns and regularities are recognized in the learning data. This means that the system can also evaluate unknown data (learning transfer) or fail to learn unknown data (overfitting) [1].

The current technology drivers for machine learning (ML) in the field of image processing are primarily automotive technology, communication and consumer electronics (smartphones), medicine and public safety. Machine learning shows strengths in classic image processing tasks such as segmentation, object recognition and classification. AI solutions with neural networks are particularly suitable for tasks for which rules are less easy to specify, such as the detection of anomalies (in images or time series) and the fusion or correlation of different data streams.

The central field of research in machine vision is the explainability of ML results. It is often not yet possible to answer the question "Why did the system make this decision?", as many ML methods do not provide any key figures for the reliability of their results. However, this is precisely what is needed to ensure acceptance by users - for example when approving project results, certifying procedures or making diagnoses in medicine. Suitable key figures are needed to assess the quality of the result. They are particularly important if safety-relevant decisions are to be derived from a result. The status report shows the current status and attempts to estimate future developments(Fig. 2).

Key issues - data use and data security

Fig. 2: The new status report on machine learningUniversities, research institutions and industrial companies are making great strides in the use of ML and AI. However, suitable framework conditions must be created, particularly with regard to data usage: Large amounts of data must be reliably secured, exchanged between project partners and protected against unauthorized access. The availability of industrial data and the freedom to use the data will form an essential basis for the economic sovereignty of an economic area in the near future. Clear regulations are therefore needed on what ownership or usage rights exist for such data, where the limits of individual rights to data lie and what rights exist to the results of learning processes for AI and ML. These regulations must be agreed within a European framework.

Fig. 2: The new status report on machine learningUniversities, research institutions and industrial companies are making great strides in the use of ML and AI. However, suitable framework conditions must be created, particularly with regard to data usage: Large amounts of data must be reliably secured, exchanged between project partners and protected against unauthorized access. The availability of industrial data and the freedom to use the data will form an essential basis for the economic sovereignty of an economic area in the near future. Clear regulations are therefore needed on what ownership or usage rights exist for such data, where the limits of individual rights to data lie and what rights exist to the results of learning processes for AI and ML. These regulations must be agreed within a European framework.

The complete status report 'Machine learning - artificial intelligence with neural networks in optical measurement and inspection systems' is available free of charge at [2]. The technical contact at the VDI is Dr.-Ing. Erik Marquardt, VDI/VDE-Gesellschaft Mess- und Automatisierungstechnik (GMA), Tel.: +49 211 6214-373, e-mail:

References:

[1] https://de.wikipedia.org/wiki/Maschinelles_Lernen

[2] www.vdi.de/publikationen