As part of its high-end/high-precision quality assurance systems, the Japanese Saki Corporation is offering a range of new automated X-ray inspection (AXI) systems, including comprehensive software solutions and flexible hardware interconnectivity for smart factory manufacturing environments.

According to Jaroslav Neuhauser, General Manager of Saki Europe, the future of electronics manufacturing demands more accurate inspection with minimal maintenance. This is why Saki's product range includes the 3Xi-M110 v3 and 3Di-LS3 15 µm inspection systems, which were shown in Europe for the first time. 3Xi-M110 v3 comes with Saki's latest optimized Planar CT software, which was developed with very fast cycle times in mind.

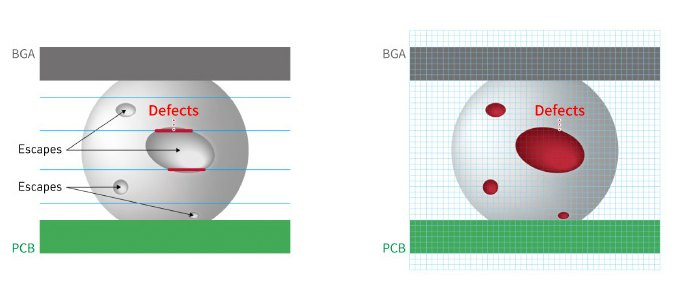

Comparison of inspection methods, Saki's solution on the right; images: Saki

Comparison of inspection methods, Saki's solution on the right; images: Saki

Jaroslav Neuhauser, General Manager of Saki EuropeThe3D AXI machine enables quality assurance with highly accurate void measurement for PCBs and components. Also new at SMTconnect 2023 is the 3Di-LS3 15 µm inspection system for high-speed and high-performance operation with high resolution and extended height measurement with an improved camera system. The system offers optional functions that can be selected in relation to production and product variants. They extend the scalability of the system and contribute to improved quality assurance. With the high-resolution (15 μm) camera system, the 3Di-LS3 system supports the inspection of assemblies with SMT components, including extremely compact and tall components.

Jaroslav Neuhauser, General Manager of Saki EuropeThe3D AXI machine enables quality assurance with highly accurate void measurement for PCBs and components. Also new at SMTconnect 2023 is the 3Di-LS3 15 µm inspection system for high-speed and high-performance operation with high resolution and extended height measurement with an improved camera system. The system offers optional functions that can be selected in relation to production and product variants. They extend the scalability of the system and contribute to improved quality assurance. With the high-resolution (15 μm) camera system, the 3Di-LS3 system supports the inspection of assemblies with SMT components, including extremely compact and tall components.

Other current inspection systems from Saki are available in the 3D SPI and AOI systems 3Si-LS2 and 3Di-LS2. They are suitable for PCBs up to 500 x 510 mm and are accompanied by a common software platform that enables seamless transition between existing systems. Saki's range for the 2D AOI sector is represented by the 2Di-LU1 system. Its underside inspection improves the productivity of production lines.