ATEcare, known in the electronics industry as a partner for testing and inspection tasks, relies on AI and deep learning for automated inspection. A promising field of application is quality assurance in the automotive industry - some things are different here than in electronics, but transfer is possible in both directions.

Automated inspection systems for checking surfaces for damage and defects are the future of quality management in the automotive industry. This enables car manufacturers and their suppliers to check quality in a cycle time-optimized manner, detect defects and faults at an early stage and ultimately manage supply chains and production processes better.

Due to the high level of competition and the dynamic behavior of end customers, the automotive industry is an obvious pioneering application for equipping the necessary sub-areas flexibly and intelligently. The aim is to detect errors in production, but also to draw conclusions from the data obtained in order to identify the causes of errors.

This is where deep learning image analysis offers new possibilities for efficient, error-free quality control. "Where today two quality employees inspect the exterior of a complete vehicle, an automatic visual inspection will be able to do this error-free and holistically in the future," explains Olaf Römer, Managing Director of ATEcare Service GmbH Co.KG. The company is a sales partner of Kitov One, one of the most modern visual inspection systems on the market. The fully automated, robot-based system combines 2D, 3D and deep learning technologies to enable industrial applications that were previously considered too complex for automated inspection. Detected surface damage: Scratches

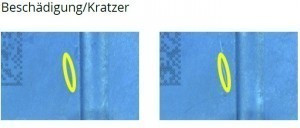

Detected surface damage: Scratches

Römer: "This is not just another robot-guided 3D measuring system, such as those already used in the automotive industry to measure gap dimensions. The Kitov One is a visual surface inspection system that does not yet exist in this flexible form in today's vehicle production. It can recognize and measure all parameters that I select and teach in via the software. This means that I can adapt the inspection to each product. Whether it's a vehicle, assembly or other supplied parts such as rims or headlights, everything can be checked before installation or customer handover. In combination with artificial intelligence (AI), this technology provides a more holistic picture of the test object and guarantees the most efficient inspection process possible."

AI can be used to train such a system to classify defects and derive decisions from them. Such deep learning behavior can, for example, capture thousands of images of a screw and not only knows where it is, but also whether it meets the quality requirements. "The system not only knows what to look for, but can also decide whether the result is within the specified tolerances," explains Römer.

According to Römer, this reduces the considerable costs of quality control in automotive production and at upstream suppliers. "Fully automated systems that learn and improve over time and adapt to the environment can massively reduce costs and increase throughput, which represents a promising return on investment for many companies. This is because the software uses preset algorithms to calculate and control effective image acquisition and processing." The system is already being used, for example, to inspect metal and plastic parts in the high-priced car segment for surface defects using automated visual inspection.

The 3D vision system integrated into the Kitov One reproducibly detects critical defects, such as surface damage to metal and plastic parts, irregularities due to poor paintwork or galvanic processes, missing components or stickers with safety instructions, and bent pins on plugs and connections. This means that the bridge from the pioneering automotive application to electronics production for this technology is foreseeable.

ATEcare works with customers to develop the optimum testing strategy, implements it in hardware and software and ensures the efficient integration of electronics production. The first deep learning applications in this environment will not be long in coming.