With a footprint of just 0.7 m², the IMDES CONDENS-IT Labo Void Buster condensation vacuum soldering system is in high demand for laboratory or prototyping applications. Thanks to the vacuum pump integrated as standard, it can remove voids while the solder is still in its optimum molten state. The result is solder joints with a surface bonding rate of up to 99 %.

Soldering under vacuum is particularly suitable for particularly demanding assemblies in terms of heat dissipation or for assemblies for power electronics. The vacuum minimizes the void components, which results in a better electrical and thermal connection. Thanks to the integrated vacuum pump, void areas of less than 5 % can be achieved with a vacuum value < 50 mbar.

The power density of modern electronic components such as power modules, hybrid and multi-chip components etc. is continuously increasing. For this reason, the quality of the solder joints must also meet ever higher requirements. Gas inclusions (voids) in the solder joints must therefore be avoided. The best way to remove these from the liquid solder is the targeted use of condensation (vapor phase) vacuum soldering. Due to the physical laws underlying condensation brazing, extremely stable process conditions are achieved in combination with vacuum technology. The specific advantages of condensation brazing are

- the environmentally friendly process

- reproducible soldering process conditions

- no overheating of PCB and components

- large-area heating of the PCB, regardless of the shape and type of printing

- absolutely uniform heating of the conductor structure

- Well reproducible temperature curves

- No oxidation

- no shielding gas required

- no labor-intensive procedures for determining desired temperature profiles.

The condensation vapor causes a thin film of liquid to penetrate even the smallest openings. This results in reliable solder joints even under components such as BGAs and FPGAs.

Condensation soldering

In the soldering process in an enclosed space, Perflourpolyeter [1] is a chemically inert and electrically neutral liquid that is heated to its boiling point and used as a heat transfer medium. Continuous heating creates a saturated vapor concentration above the liquid at the same temperature as the boiling liquid.

If assembled PCBs are placed in this space, the vapor will condense on the surface of the PCB because it has a lower temperature than the condensing vapor. In simple terms, this corresponds to the situation when a person wearing glasses enters a warm room from the cold: first the glasses mist up with drops of condensation, which then gradually evaporate again.

If the circuit board remains in the vapor, its temperature rises until the entire surface has the same temperature as the vapor. Condensed liquid is converted back into vapor. As the solder alloys have a lower melting temperature than the temperature of the vapor, they begin to melt. When the medium cools down again, the solder hardens and the finished soldered PCBs can be removed from the process chamber.

Standard reflow and vacuum reflow process in comparison

Standard reflow and vacuum reflow process in comparison

Blowholes and voids

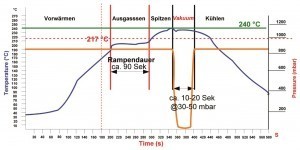

Soldering profile in the condensation vacuum soldering process: Max. 240°C peak temperature; if ramp profile necessary, ramp between 190 and 200°C, ramp duration approx. 90 sec, delta T in ramp and peak 2 to 5°C, temperature in the vacuum approx. 10°C above liquidus; immediate cooling after the end of evacuationVoidsare inclusions in the solder joint that occur during soldering in the area of component connections. Causes that lead to the formation of voids during the soldering process are

Soldering profile in the condensation vacuum soldering process: Max. 240°C peak temperature; if ramp profile necessary, ramp between 190 and 200°C, ramp duration approx. 90 sec, delta T in ramp and peak 2 to 5°C, temperature in the vacuum approx. 10°C above liquidus; immediate cooling after the end of evacuationVoidsare inclusions in the solder joint that occur during soldering in the area of component connections. Causes that lead to the formation of voids during the soldering process are

- Crystalline inclusions of fluxes

- Bubbles due to outgassing processes of solvents

- Outgassing of non-polymerized

photoresists from the solder resists - Inclusions of air under components as a result of

Unsuitable paste pressure or pad design - reactive gases generated during the removal

oxide layers caused by flux - metallic defects and

- interactions between different materials and their diffusion properties.

Negative consequences of voids are reduced strength of solder joints, reduced vibration resistance, limited heat dissipation from components and structures, performance limitations in high-frequency applications and thus reduced load capacity and service life of the assembly.

A liquid film surrounds the assembly. When it passes into the vapor phase, the temperature specified by the boiling point of the medium prevails evenly and everywhere. Ifthe cooling and thus solidification phase of the soldertakes placein a vacuum, trapped gases can escape from the still liquid solder. The combination of condensation brazing and vacuum in one process offers the following advantages:

A liquid film surrounds the assembly. When it passes into the vapor phase, the temperature specified by the boiling point of the medium prevails evenly and everywhere. Ifthe cooling and thus solidification phase of the soldertakes placein a vacuum, trapped gases can escape from the still liquid solder. The combination of condensation brazing and vacuum in one process offers the following advantages:

- void-free soldering (void percentage

from < 15 % to 5 %) - Surface bonding up to 99 %, improved wetting

wetting, better filling

of micro-via' s and THT solder joints - 100% oxygen-free soldering process

- Overheating, component damage

and delamination cannot occur.

The maximum temperature for lead-free soldering cannot exceed 240 °C. Soldering temperatures from 135 °C to 240 °C are possible with the system. The distribution of thermal energy on the assembly is optimal. Three-dimensional products can be processed without any problems.

Standard reflow technology

The standard reflow process is summarized as shown in the diagram: The solder paste is applied to the PCBs using a stencil printer or dispenser before assembly begins. The assembled components adhere to the sticky paste.

Reflow soldering is carried out using infrared radiation, full convection or vapor phase soldering. Unfortunately, this can result in voids (air and other gas inclusions in the solder joints). Lower 'void rates' can only be achieved with soldering processes in which the molten solder is exposed to a vacuum. The residues still contained in the solder joint can escape more easily due to the vacuum.

The vapor phase vacuum technology

Condensation vacuum technology and the use of the vacuum soldering process in particular therefore offer an optimum solution for the greatest possible reduction in void formation. In vacuum vapor phase reflow soldering, the heating process takes place in the absence of air. This causes air and other gas inclusions to be displaced from the solder joints. This results in void-free solder joints that dissipate heat optimally.

A process chamber for the soldering process, vacuum and cooling

In the CONDENS IT LABO Void Buster, the entire reflow soldering vacuum and cooling process takes place in a hermetically sealed stainless steel process chamber. The maximum module size is 300 x 245 mm x 40 mm. Due to the hermetically sealed process chambers, the 'evaporation loss' during soldering is low, resulting in lower medium consumption.

During condensation soldering, a liquid film builds up with the help of the heat-conducting medium Galden, which surrounds the entire assembly and vaporizes. The vapor condenses on the assembly until a soldering temperature of 240 °C is reached (e.g. when using HS240). The perfluoropolyether (Galden) medium consists of carbon, fluorine and oxygen.

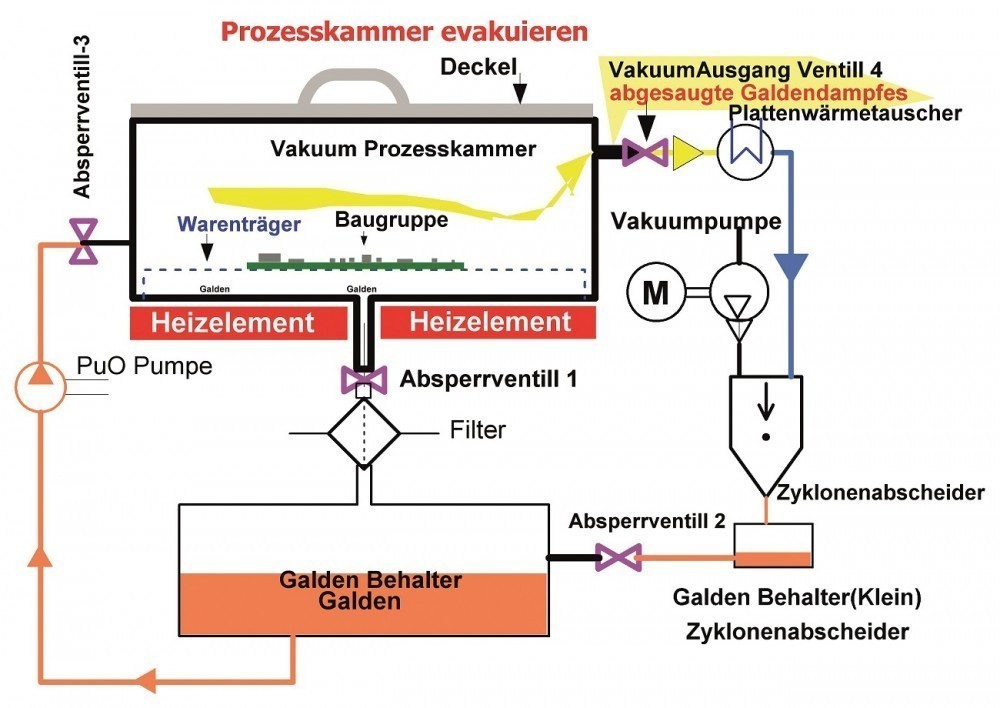

After the soldering process, the hot Galden, which is still present at the bottom of the process chamber, is first drained via a valve and flows out of the process chamber cleaned via a filter at the bottom of the Galden storage container for reuse. The process chamber is then evacuated. A vacuum is created during evacuation, which also guarantees rapid drying of the soldering material.

At the same time, the hot process gas is extracted and cooled by a heat exchanger. The Galden becomes liquid again. This forms small droplets in the air extracted from the process chamber and other gases, including the solder paste.

The air with the Galden droplets is passed through a cyclone filter and separated into liquid and gas. The air leaves the process chamber via the vacuum pump and the Galden enters the storage tank of the cyclone filter.

After evacuation, the assembly is transferred to the cooling process and air is blown into the process chamber via a nozzle system to gently bring the assemblies to lower temperatures before the actual cooling process. The assembly is not moved during the entire process and does not require a hot base plate or additional heating. During the evacuation process, components cannot slip or blow off or become too hot.

Process sequence in detail

The final phase of the process sequence

The final phase of the process sequence

The process chamber initially contains the empty product carrier, but no heat transfer medium. The infrared heating is not switched on. The lid, which is located on the upper side of the process chamber, is now opened. The product carrier is loaded manually with pre-assembled modules and the lid is closed. The condensation vacuum soldering process is started with the start button: The heating is switched on, a pump (PuO) is used to pump the required amount of Galden from the storage container into the process chamber. The process fluid is heated up to its boiling point. The boiling point is also the process temperature. In the vapor zone, vapor builds up around the entire assembly, condenses on the assembly and forms a closed liquid film.

The vapour zone stabilizes at the level of the assembly. The assembly heats up completely to the vapor temperature. The condensation then stops automatically and the vapor zone continues to rise. The soldering process is then completed. To do this, the shut-off valve 1 is opened. The liquid-hot medium contained in the process chamber flows through a filter and is thus cleaned from the process chamber at the bottom of the Galden storage tank. Now the shut-off valve 1 is closed and then the process chamber is evacuated (approx. 10-20 seconds at 30-50 mbar - these parameters are programmable) - the heating was still switched on during all these process steps. Only now is it switched off and the cooling phase begins. The complete vacuum soldering process is now complete and the lid can be opened to remove the soldered assemblies from the product carrier.

References:

[1] Perfluoropolyeter is marketed by Solvay Solexis under the name 'Galden'