In addition to stencil printing, there are other application and dispensing methods for solder pastes, such as those used in electronics as conductive connections - for example micro dispensing. If micro-dispensing is to be implemented reproducibly, it depends on the right combination of solder pastes and dispensing system. In the following article, John P. Kummer GmbH, in cooperation with NSW-Automation Sdn Bhd, Malaysia, presents the appropriate technology with which it will also be possible to dispense solder pastes with a dot size of 50 µm Ø in the future.

Despite optimization of the dispensing parameters on the dispensers, both failed and were unable to provide a consistent dispensing result over 4000 dispensings

Despite optimization of the dispensing parameters on the dispensers, both failed and were unable to provide a consistent dispensing result over 4000 dispensings Fig. 1: Cartridge dispenser (left) vs. screw conveyor

Fig. 1: Cartridge dispenser (left) vs. screw conveyor

valve (right):Micro-dispensing of solder paste offers numerous advantages for inhomogeneous designs with different components on one assembly, which are installed as small and space-saving as possible. The process, which is based on the unique squeeze pump principle, is also suitable for adhesives, biological substances, silicones, sealing materials or phosphorus. For use in the field of soldering pastes, the basic principles should be considered first:

The flow behavior of solder pastes

Solder pastes essentially consist of flux and solder powder. This combination results in viscoelastic behavior, so that solder pastes remain elastic/stable at low shear, but become less viscous and therefore more flowable at high shear. Factors such as the density, the filling level or the alloy of the solder pastes also have an influence on the flow behavior. The biggest problem, however, is the particle size of the fillers, as these can clog the needle of a dispensing system for various reasons. Rule of thumb: A dispensing needle should be selected whose ID:Ø is 5-7 times larger than the selected particle size.

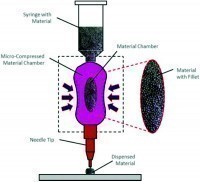

Fig. 2: NSW squeezing pump - operating principleItshould also be noted that a finer particle size tends to cold solder more easily. This is due to the higher surface structure and smaller mass of the particles. Dispensing methods such as screw or cartridge dispensers, which work with high pressures or mechanical forces, therefore reach their limits with micro dispensing.

Fig. 2: NSW squeezing pump - operating principleItshould also be noted that a finer particle size tends to cold solder more easily. This is due to the higher surface structure and smaller mass of the particles. Dispensing methods such as screw or cartridge dispensers, which work with high pressures or mechanical forces, therefore reach their limits with micro dispensing.

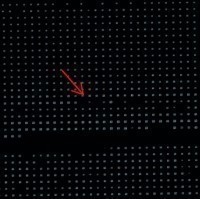

For a comparison, dots were dispensed onto a wafer using a screw dispensing valve and a pneumatic cartridge dispenser and examined. The aim of the comparison was to achieve a reproducible dot size of 100 µm over 4000 dots. This showed that a precise guidance system as the last important link in the dispensing process is essential for a perfect result. The S400H from NSW-Automation with a repeat accuracy of ±5 µm was selected for the test. The dispensing distance to the wafer surface was 30 µm. As a rule of thumb, approximately ⅓ of the desired dot size should be selected as the dispensing distance. Solder paste used: SAC305 T6SG 78 % with ceramic dispensing needle with Ø100 µmI Fig. 4: Dot size Ø in mm distribution over 4000 dispensing points

Fig. 4: Dot size Ø in mm distribution over 4000 dispensing points Fig. 3: Section of 4000 dispensing points, created with NSW squeezing pump

Fig. 3: Section of 4000 dispensing points, created with NSW squeezing pump

NSW Squeezing Pump

The NSW squeezing pump was also tested under the same setup. This works according to the squeezing pump principle, in which a flexible squeezing chamber receives the material from a previously stored cartridge and precisely dispenses the solder paste onto the wafer surface without deformation. NSW has further tightened the requirements in the tests for the squeezing pump and set a dot size of 80 µm as the specification.

The subsequent measurement of the individual dots showed that they could be applied within a tolerance range of just ±8 µm.

- Smallest dispensing dot: 72 µm

- Largest dispensing point: 84 µm

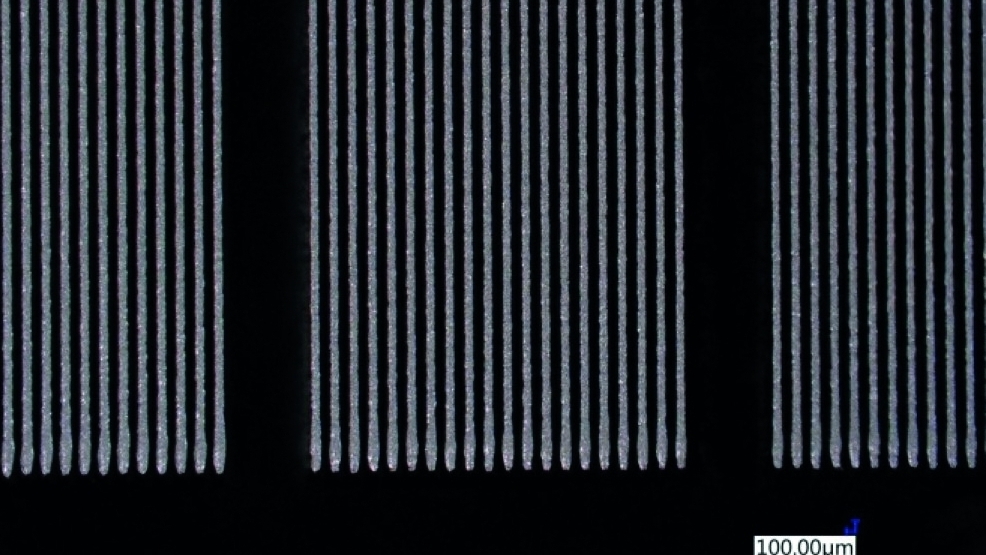

Fig. 7: 80 µm web width (enlarged)

Fig. 7: 80 µm web width (enlarged) Fig. 6: Section of 400 lines with 80 µm web width

Fig. 6: Section of 400 lines with 80 µm web width Fig. 5: Dispensing point measurement Ø 80Thefollowing chart(Fig. 4) shows the point size distribution over 4000 points. It can be seen that the lion's share of the dispensing points is at an Ø of 80 µm.

Fig. 5: Dispensing point measurement Ø 80Thefollowing chart(Fig. 4) shows the point size distribution over 4000 points. It can be seen that the lion's share of the dispensing points is at an Ø of 80 µm.

The result of the test series shows that it is possible to reproducibly dispense solder pastes with a dot size of 80 µm using the NSW squeezing pump. A further series of tests was also carried out with the NSW squeezing pump and solder paste. In this series, 400 lines were dispensed, each with a web width of 80 µm. The result shows the same reproducibility as with the dispensing of dots. The entire study, as well as further information on the NSW squeezing pump or other NSW dispensing equipment, is available from JP Kummer on request. -dir/vti-