The innovative EMI shielding SnapShot from XGR Technologies is a new addition to the product range of DICO Electronic GmbH, Schwabach. Designed for easy mounting on printed circuit boards, SnapShot shielding is made of an extremely lightweight, metallized plastic material that can be thermoformed into virtually any design. SnapShot offers excellent shielding performance compared to perforated or frame/cap-type metallic shielding elements. The material was introduced to the market in 2002 by W. L. Gore & Associates and has since been successful in numerous applications in medical, military, aerospace, industrial and computer electronics.

Proven technology for years

William Candy, President of XGR Technologies, is one of the original developers of SnapShot and a former W. L. Gore & Associates engineer. He founded XGR Technologies in 2018 with a mission to provide innovative solutions for EMI shielding on printed circuit boards. Through a partnership with a technology investor group, he was able to acquire all SnapShot production, rights and inventory from W. L. Gore & Associates. As a result, SnapShot will continue to be manufactured with the same equipment, materials and skilled operators to the same high quality standards at the same location. At the end of 2019, XGR's quality management system was certified to ISO 9001:2015 and XGR is ITAR registered.

SnapShot features and installation

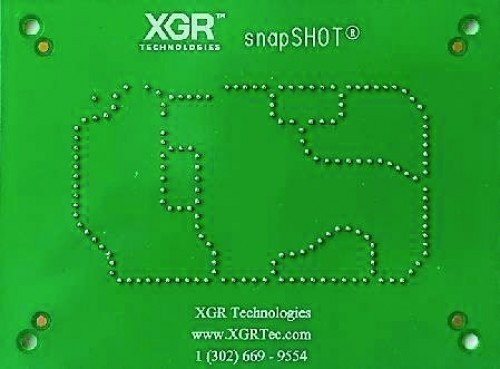

SnapShot is a shield with a special construction. The material used is the thermoplastic polyetherimide (PEI), which is both extremely light and thermally malleable. The PEI is provided with a tin plating on the outside so that it is conductive. The shielding is mounted on the circuit board by "snap-in-place", i.e. it is attached to the circuit board by snapping in its oval holes, which are located along the edges or around the circumference of the cavities, via previously applied solder balls. The latter can be assembled manually or automatically. This creates a very strong electromechanical connection. The properties of SnapShot EMI shielding are as follows:

- Material thickness: 0.125 mm

- Metallization layer thickness: 5 µ (SEM)

- Planar shielding: 75 dB (ASTM D4935)

- Surface resistance: 0.025 Ω/□ (ASTM F390)

- Adhesion strength of the metallization: 5B (ASTM D3359)

- Dielectric strength: 80 kV/mm (ASTM D149)

- Softening temperature: 215 °C (ASTM D1525)

- (Continuous) operating temperature: 170 °C

Comparison of shielding effectivenessThedesign flexibility isalsoenormous. Each application is custom designed to meet the individual size and shape requirements of the PCB layout. Almost any shape is possible: single or multi-cavities, multiple heights within an application, low profiles down to 'zero' distance between components and inner shielding surface, with or without perforation, 'dog house' to integrate PCB connectors into the shielding, etc.

Comparison of shielding effectivenessThedesign flexibility isalsoenormous. Each application is custom designed to meet the individual size and shape requirements of the PCB layout. Almost any shape is possible: single or multi-cavities, multiple heights within an application, low profiles down to 'zero' distance between components and inner shielding surface, with or without perforation, 'dog house' to integrate PCB connectors into the shielding, etc.

SnapShot EMI shields are also extremely robust and durable. They are proven to be resistant to shock, vibration, moisture and ageing and are ideal for industrial and military mobile devices.

As the SnapShot EMI shielding is only installed after reflow soldering, unhindered inspection and reworking of the assembled PCB is possible. The shielding can also be removed and replaced by hand without damaging the PCB and without the need for re-soldering. The advantages of SnapShot EMI shields include in particular

- ultra-lightweight, ideal for applications where every gram counts

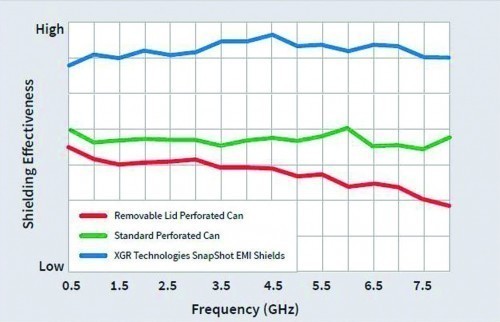

- excellent shielding properties (outperforms comparable shielding options in effectiveness from below 1 GHz to 12 GHz, relative shielding effectiveness compared to traditional metal housing: 10 dB per unit)

- Non-conductive inner surface reduces electromagnetic coupling with conductor structures, minimizes overall volume and eliminates short circuit risk

To facilitate the use of SnapShot EMI shielding, XGR offers solder balls in tape-and-reel packaging for processing with SMD pick-and-place machines. Further information or a free sample can be obtained from the sales partner for the regions of Germany, Austria, Switzerland and Liechtenstein, DICO Electronic GmbH, or directly from XGR Technologies.