Although the electronics industry in the USA has been hit just as hard by the coronavirus pandemic as in Europe, it continues to develop unperturbed. Despite the massive work restrictions, the industry association IPC has so far succeeded in continuing its work on new standards in a targeted manner. However, the ongoing diversification of electronic designs and technologies is presenting it with new tasks that are beyond its current capabilities. It has therefore sought out new cooperation partners, mainly based in the USA. Is this a consequence of US President Trump's policies?

The coronavirus pandemic has also left its mark on the US PCB industry. Since the start of Covid-19 in the spring of this year, it has been more like a rollercoaster.

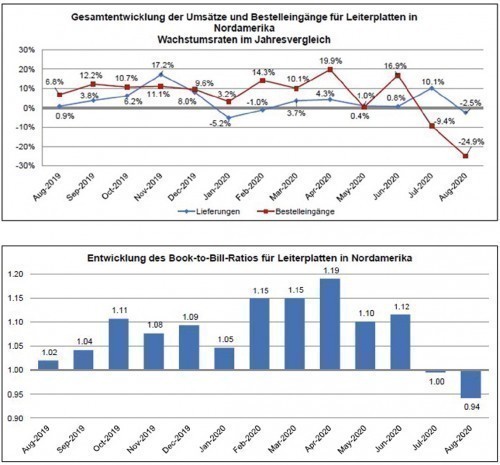

Shawn DuBravac, Chief Economist of the industry association IPC, describes the situation in his monthly report on the development of the North American PCB industry for August 2020 as follows: "The first few months of the pandemic saw historic growth as supply from China was limited due to the pandemic and many manufacturers sought alternative capacity (note: a partially similar situation was also experienced in Germany at the time). In the last two months, however, the flow of orders has slowed rapidly as the economic recovery slows and customers in the downstream industry become more cautious in the face of increasing uncertainty. August saw the lowest order intake since July 2016. While the supply chain remains healthy, slowing downstream demand is weighing on the PCB industry and is likely to remain a headwind in the coming months."

Total PCB shipments in North America were 2.5% lower in August 2020 compared to the same month last year. Compared to July 2020, there was a significant drop in August. Incoming orders were even worse in July and August. In August, incoming orders fell drastically by 24.9% compared to the previous year. A bad sign for PCB producers, at least in the second half of 2020, but it is hoped that things will pick up again in 2021.

Stable standardization work despite corona

Although nobody in the USA, and therefore also in the IPC, knows what will happen with the coronavirus pandemic on the one hand and the trade disputes and sanctions between the USA and China on the other, the industry association is aware that international standardization work must continue despite the current fundamental changes in the working conditions of the relevant standardization working groups (committees) and international economic policy disputes. It is an essential part of the progress of the global electronics industry and must not be damaged by the current problems of the coronavirus pandemic or by national economic policy 'games'. The IPC committees also had to increasingly switch to remote working or video conferencing instead of meeting in person at major industry events such as IPC APEX, as was previously the case.

A look at the IPC Status of Standardization in [1] shows that the professional association succeeded in publishing 13 new or updated standards in the period from April to October of this year. In addition, there are 25 translations, which were mainly published as original English editions in 2019 and 2020. Examples of languages: German, Japanese, Chinese, Thai, Russian, Spanish, French, Polish, Dutch. In terms of the number of translations, Chinese, Spanish and German are in the lead. This is evidence that the global acceptance of IPC standards is unbroken.

The IPC Status of Standardization overview also shows that 47 standards (including three handbooks, i.e. documents that underpin certain standards) were in progress in mid-October of this year, 19 of which are completely new in terms of subject matter. In progress here means that they are currently in one of the four usual stages of work at the IPC:

- New projects (Project Approved)

- Working Draft

- Final Draft for Industry Review

- Proposed Standard for Ballot

Six standards currently in progress deal with printed electronics, including those on flexible substrates. Printed electronics has been categorized as a key topic in the IPC for around six years and is becoming increasingly important. Development of the book-to-bill ratio and the overall development of sales and orders received in the North American PCB industry from August 2019 to August 2020

Development of the book-to-bill ratio and the overall development of sales and orders received in the North American PCB industry from August 2019 to August 2020

The creation of standards for e-textiles is also a new field of activity for the industry association. In development are:

- IPC-8941 - Guideline on Connections for E-Textiles

- IPC-8981 - Quality and Reliability of E-Textiles Wearables

With the first-time development of a new standard for the realization of assemblies based on polymers, the IPC is further expanding its field of work to organic electronics:

- IPC-5262 - Design, Critical Process and Acceptance Requirements for Polymeric Applications

Two forthcoming documents on general topics of overarching importance are intended to support companies in safeguarding production:

- IPC-2551 - International Standard for Digital Twins

- IPC-1792 - Standard for Cybersecurity Management in the Manufacturing Industry Supply Chain

Considering that 30 years ago the IPC standards dealt almost exclusively with the concerns of classic PCB technology, the current range of work has become much broader and follows both the diversification trend in electronics and political developments.

Updated and clarified: IPC-2222, IPC-A-600, J-STD-001, IPC-A-610

Four of the documents that the IPC published again in the period July-October 2020 in updated, clarified and expanded versions are among the long-standing 'basics' for electronics manufacturing. With the exception of IPC-2222, they are revised approximately every two to three years. IPC-2222 is an exception here because its predecessor IPC-2222A was published in December 2010 and its revision as a basic standard for design was long overdue.

The four updated basic standards are

- IPC-2222B - Sectional Design Standard for Rigid Organic Printed Boards, 36 pages, October 2020

- IPC-A-600K: Acceptability of Printed Boards, 190 pages, July 2020. The revised 'daughter document' to this, IPC-6012E Qualification and Performance Specification for Rigid Printed Boards, was already published in March 2020

- IPC J-STD-001H: Requirements for Soldered Electrical and Electronic Assemblies, 108 pages, September 2020

- IPC-A-610H: Acceptability of Electronic Assemblies, 416 pages, September 2020

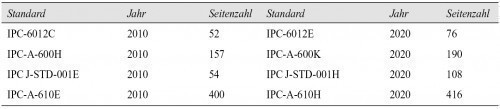

A brief formal comparison of four of the new documents mentioned with their predecessors from 2010 shows that the standards have not only become more precise in terms of content from edition to edition, but have also grown in terms of pages(Table 1). The reason is simple: the variety of electronics solutions, e.g. in terms of the range of components and operating conditions, but also in terms of technologies, has increased over the years. Tab. 1: Increase in the number of pages of the four basic documents IPC-6012, IPC-A-600, IPC J-STD-001 and IPC-A-610 between 2010 and 2020

Tab. 1: Increase in the number of pages of the four basic documents IPC-6012, IPC-A-600, IPC J-STD-001 and IPC-A-610 between 2010 and 2020

At the same time, the reliability requirements in use are growing, not least due to the increasing circuit complexity of devices and systems. Examples of this include medical, military and aviation/space technology. To this end, the association is working with the industry to develop addendums, i.e. supplementary or supporting documents to the basic documents with special requirements for the boards or assemblies. IPC/WHMA-A-620D-S was published in October 2020: Space and Military Applications Electronic Hardware Addendum to IPC/WHMA-A-620D.

What's new in the base documents?

Below are examples of updates in three of the latest standards compared to their predecessor documents.

IPC-A-600K

- Updated pattern definitions: Conductor width, external residual ring and surface coating

- Updated dielectric materials, laminate voids and laminate cracks, hole wall impurity removal, negative etchback, layer-to-layer spacing

- Trace overhang, foil plus plating, solder mask thickness

- Significant changes to the plated through hole section: microvia contact sizing, copper wrap plating, copper cap plating, copper filled vias, back drilled holes

- Significant changes to metal core PCBs

- Updated criteria for solderability testing and hairline cracking

- Changes to the acceptance of base material surfaces

IPC J-STD-001H

Representatives from 27 countries have now contributed to the revision of this standard, which represents an increase of nine countries. This demonstrates the important coordinating role of the document in the international electronics industry.

- The supplement IPC-J-STD-001G-AM1 to the base document, which was published separately in 2018 with a revision of the more than 25-year-old recommendations on board cleaning and residual residues, has now finally been integrated into IPC-J-STD-001H

- Section 8.0 (Cleaning and Residue Requirements Section) is a completely new part of the standard that has been universally agreed with the industry. It contains industry-standard requirements for the cleaning of assemblies and residues on them

- The definition of 1.56 μg NaCl equivalent/cm2 as the value for the specific resistance of the solvent extract (ROSE) is no longer an acceptable basis for the qualification of a manufacturing process

- IPC-WP-019B (An Overview on Global Change in Ionic Cleanliness Requirements) contains explanations and justifications for section 8.0 "Cleaning and residue requirements" as a white paper

- The item added as Appendix D contains suggestions on the use of X-rays for the acceptance of brazed joints

- References to the International Space Station symbol have been removed

- With the issuance of an additional automotive addendum (IPC J-STD-001GA/IPC-A-610GA, 'Automotive Addendum to IPC J-STD-001G Requirements for Soldered Electrical and Electronic Assemblies and IPC-A-610G Acceptability of Electronic Assemblies' in March 2020, all reference symbols were removed from the base document to avoid confusion for readers. Note: Because the addendum referred to IPC J-STD-001G and IPC-A-610G, it is expected that the addendum will be aligned with IPC J-STD-001H in the near future

- New criteria for winding connections

IPC-A-610H

Representatives from 29 countries were involved in the revision of this standard, which represents an increase of eleven countries compared to the previous document. This means that a high level of international consensus was also achieved for this document.

- All target conditions have been removed from the document, as was already the case in IPC/WHMA-A-620D 'Requirements and Acceptance for Cable and Wire Harness Assemblies'. This standard was already published in January 2020

- General updates throughout the standard

- New criteria for winding connections

- The ESD issue has been moved to a separate annex

- Separation of the board assembly from the cable or wire harness

- The criteria for jumper wires have been summarized in a separate chapter

- New technical criteria, e.g. for solder on the plastic housing of components

- Inclusion of new component connections such as P-shaped and pre-tinned butt solder joints/I connections (butt/I)

- Substantial revision of the chapter on protective coatings

Smart factory brings new challenges

Looking at the trend towards smart individual factories in accordance with Industry 4.0 using local 5G networks and the linking of groups of smart factories using global 5G networks, it is clear that the standardization of electronics production faces new challenges: Ensuring the highest reliability of production itself as well as the reliability of electronic assemblies, devices and systems and ensuring cyber security. This is particularly important for the broad acceptance of autonomous vehicles in the future. The new IPC-1792 standard (Standard for Cybersecurity Management in the Manufacturing Industry Supply Chain), which is currently being developed, shows that the association is aware of the growing importance of this topic and that companies should be supported in this regard.

In search of partners

With its logo text 'Build Electronics Better', the IPC wants to convey to the viewer that it is endeavouring to keep pace with technical, technological and organizational developments in its standardization work. This is also supported by the new topics mentioned above, which have been incorporated into the standardization work. The range of topics to be addressed by the association is thus constantly expanding. Various logos

Various logos

However, as already mentioned in this article, it is not easy for a single industry association to cope with the growing field of electronics production on its own due to the increasing diversification of electronics solutions in terms of design, component basis, manufacturing technologies and also fields of application. This is particularly true when it comes to specialized experience in specific areas of electronics application.

For this reason, the IPC has already cooperated in the past with other US associations such as WHMA (cables, cable harnesses), JEDEC (components) or SMEMA (SMD assembly equipment, since 1999 in association with the IPC as the SMEMA Council of IPC) on specific topics in standards work. Cooperation has also been entered into with foreign associations such as JPCA (Japanese PCB Manufacturers Association) and CPCA (Chinese PCB Manufacturers Association). However, the content and timing of the cooperation appears to vary considerably, even sporadically. Even the JPCA apparently only opened up its wealth of experience to the IPC for standardization work on a sporadic basis. The joint IPC/JPCA standards for HDI boards, for example, have long been on the verge of revision. In the meantime, leading board manufacturers have made the transition to highly complex chip substrates and are already moving in the direction of very complicated carriers for chiplet technology. All this (and more) has so far been missing from the IPC.

There is only some current cooperation between the IPC and JPCA on printed electronics. In the IPC's Status of Standardization mentioned above, there is currently not a single one of the earlier joint IPC/JPCA standards that would undergo an update. New joint documents are probably not in sight either [1]. However, technology continues to develop relentlessly, so new partners must be found or cooperation with existing partners must be activated and raised to a higher level.

The cooperation initiated by the IPC in recent years with the Chinese CPCA to create new standards based on a division of labor has so far produced few results, despite some concrete initial activities. The current tense situation between the USA and China, particularly in the electronics industry, as well as the USA's push to 'bring home' foreign production, offers China little incentive to become involved in US associations such as the IPC. This is no wonder, as the IPC has recently positioned itself repeatedly and increasingly clearly in the direction of repatriating American production to the USA, including, of course, above all production from China. The IPC has several representative offices in China.

'America first' has become an unmistakable guiding principle of the association, as has the promotion of independence from production sites in Asia and Europe. In a press release dated 24 July 2020, the IPC expressly welcomed the National Defense Authorization Act (NDAA) passed by the US Senate. This was prepared by the IPC and contains measures to strengthen the resilience and security of the US defense electronics industrial base. The idea is that commercial (non-ITAR) PCBs and PCB assemblies required for the manufacture of sensitive US defense systems in the USA should increasingly be produced in the USA itself over the next ten years or, as an exception, possibly in countries that are trustworthy to the USA. But what are all 'sensitive systems' according to the American interpretation? Is it - as in the past with sanctions - a 'rubber band' as with dual-use products?

Partnership-based cooperation with trade associations in Europe has also not made much progress in recent years. For example, the IPC has shifted its focus to organizing conferences, seminars and similar events via its own office in Brussels, in direct competition with various European and German service providers. The office in Brussels was originally established there in order to lobby the EU authorities - mostly in the sense of delaying new EU decisions that could 'harm' the USA. In summary, the situation for the IPC under the Trump administration is becoming increasingly complicated in terms of its own work and the search for efficient cooperation partners abroad.

For purely subjective reasons, even larger European companies are more willing to work directly on selected IPC standardization topics from time to time, as was the case with IPC-9797 'Press-fit Standard for Automotive Requirements and other High-Reliability Applications', for example. The document was published in June 2020.

Stay in the country

The IPC's activities this year to acquire new partners for standardization work and the further training activities based on this lead to the assumption that the association has decided, taking into account the strange policies of the Trump administration, to make greater use of the opportunities available in the USA itself than before and no longer rely so much on foreign associations. Motto: USA first, safety first - stay at home. This applies in particular to new and cutting-edge technologies.

Around two years ago, the IPC established a working relationship with the US association SGIA (based in the screen printing industry) [2]. SGIA stands for Printing United Alliance and is the trade association for professionals from the industrial, graphics, apparel, textile, electronics, packaging and commercial printing sectors. The joint standard IPC/SGIA-5222 'Process Guideline for Screen Printing for Printed Electronics (Additive Manufacturing)' has been in progress since the start of the collaboration. It has currently reached the working draft stage. It should be noted here that printed electronics are playing a growing role in military and security electronics.

Whether the IPC's search for partners was inspired more by the coronavirus pandemic or by President Trump's policies remains to be seen; in any case, it developed an activity phase between mid-June and mid-September 2020, during which it entered into negotiations with four different US interest groups to intensify cooperation and concluded corresponding agreements with them. The author has never experienced such an action phase at the IPC before - and he has been involved with it for almost 30 years.

Automotive Industry Action Group (AIAG)

On 22 June 2020, it was announced that IPC and the Automotive Industry Action Group (AIAG) had renewed their cooperation agreement with the aim of deepening cooperation, including in standardization [3]. AIAG is a powerful non-profit organization with 3903 member companies, where OEMs, suppliers, service providers, government agencies and individuals from academia have been working together for more than 38 years to reduce costs and complexity in the automotive supply chain.

According to the press release, there are good reasons for the increased cooperation between IPC and AIAG: With electronic systems expected to reach 50 percent of total vehicle costs by 2030, electronics companies are critical in the automotive supply chain as drivers of quality and support for OEM development goals. In addition to sharing best practices for quality and supply chain, the industry associations will work together to educate the automotive supply chain on compliance requirements, align IPC standards and AIAG guidelines from both industries, and jointly prepare training that builds on professional standards. Part of the IPC-AIAG partnership is the possibility of free AIAG membership for IPC members who are direct suppliers to the automotive industry.

High Density Package Users Group (HDP)

A press release dated June 24, 2020 states that the IPC and the High Density Package Users Group International Inc. (HDP) have signed a Memorandum of Understanding (MoU) with the aim of strengthening their partnership and technical cooperation. The aim is to jointly seek ways to develop new and disruptive HDI (High Density Interconnect) technologies [4]. The HDP User Group is a non-profit organization of companies involved in the supply chain for manufacturing products with high-density component packaging. Its mission is to drive innovation in the electronics industry by reducing costs and time to market through active collaboration.

At [5] there is a comprehensive overview of the numerous projects already completed in recent years and the work currently underway. This should provide the IPC with a treasure trove for updating or updating its HDI standards.

Examples of projects completed in the last two years:

- Counterfeit PCB Materials

- Future HDI (Trend BGA Pitch, HDI PCB layer count etc.)

- FCBGA Package Warpage

- High Density BGA

- High Frequency Loss from Copper Topology

- Lead Free PWB Materials Reliability

- Ultra-Thin HDI Multi-Purpose Test Vehicle

Examples of ongoing projects and projects completed in 2020:

- Backdrill under BGA

- Component Rework Reliability

- Design Related PWB Material Damage

- Innerlayer Copper Balancing

- Photonic Soldering

- Low Ag Alloy Solderpaste Reliability - BGA Leg

- Reliability and Power Cycles

International Electronics Manufacturing Initiative (iNEMI)

On August 3, 2020, it was announced that IPC and iNEMI have signed a Memorandum of Understanding (MoU) aimed at strengthening cooperation and focusing on the future of electronics manufacturing. iNEMI is by its own definition a non-profit, highly efficient R & D consortium of leading electronics manufacturers, suppliers, associations, government agencies and universities with about 90 members, including many well-known companies such as Dell, Lenovo, DuPont, Ibiden, HP, Intel, from the German side also Fraunhofer IZM and Heraeus [6]. The consortium sees it as its mission to research and accelerate improvements in the electronics industry for a sustainable future.

IPC and iNEMI have worked successfully for two decades on IPC standards, projects requiring round robin testing for various programs, roadmaps and events between the two organizations. Most recently, a best practice document on the disinfection of electronic products and assemblies was created, which can also be used during the coronavirus pandemic. The agreement is intended to enable close cooperation to examine the technological requirements of the electronics manufacturing supply chain and to achieve greater benefits for the respective membership. Numerous examples of projects can be found at [7], for example

- Eco-Design Leadership Best Practices for Sustainable Electronics

- Impact of Voiding on Thermal Performance of BTCs

Power Sources Manufacturers Association (PSMA)

On 17 September 2020, the IPC and PCMA (Power Sources Manufacturers Association) signed a Memorandum of Understanding (MoU) in which they committed to building a close relationship between the two organizations, with a focus on standards development, education and training [8]. PSMA is a non-profit organization in the US state of California that deals with power electronics packaging for various types of electronic devices and systems. Its members come from government, academia and industry throughout the US and abroad. Examples of international members of PSMA

Examples of international members of PSMA

Standards for the development and production of power electronics are still a weak point in the IPC's standards work, although the topic of power supply is becoming increasingly important for data centers and e-mobility, for example, as is the development towards integrated power supplies with embedded components. An important PSMA document is the Power Technology Roadmap, which, according to the association, provides a consolidated outlook on the trends in power conversion technologies for the next two to five years [9].

Conclusion: Many opportunities for the IPC

Up to now, the IPC has been characterized by the fact that it is primarily an industry association for the industry: by practitioners for practitioners. By intensifying cooperation with the organizations presented, the IPC gains access to new sources of knowledge and experience, including many scientific institutions from the university sector, but also many users of electronics. It is now largely up to the IPC how it understands how to integrate its partner organizations with their great potential into its work. It seems that there is plenty of material for the successful continuation and expansion of its standardization work. This would also be advantageous for the German electronics industry, as the IPC remains the standardization organization that has so far best managed to provide and update important standards relatively quickly in important areas of electronics manufacturing. However, one important question remains at the end: Will 'America First' mean that the knowledge gained from the new collaborations will no longer be available globally? After all, we must not forget that new, up-to-date standards are also knowledge transfer, for example to the Chinese.