Limburg-based JDM/EMS expert Limtronik GmbH is expecting an increase in orders this year and wants to be prepared accordingly: The company is also integrating additional placement machines from Fuji Europe when upgrading its machinery.

"We have started the new year with a very good order situation and expect capacity utilization from the third quarter onwards, which will require an expansion of SMT capacity. That's why we used productronica in November 2021 to get an overview of the SMT assembly market," explains Gerd Ohl, Managing Director of Limtronik GmbH. After reviewing numerous solutions, the company once again opted for Fuji. Various assembly solutions from this supplier are already in use in Limburg.

Limtronik has evolved from a traditional manufacturing company to a joint development manufacturing (JDM) partner in the field of electronic manufacturing services (EMS): Customers are not only supported in the production of electronic assemblies and customized systems, but also in their development.

Ohl: "Our business model involves making our factory, our specialists and our technological expertise available. So we sell capacity and expertise." According to the Managing Director, if customers want to call on these factors, they have a right to be provided with the best possible performance and speed according to their needs. "As we see room for maneuver in the future, we have created additional SMT capacities in good time."

High requirements met with NXT series

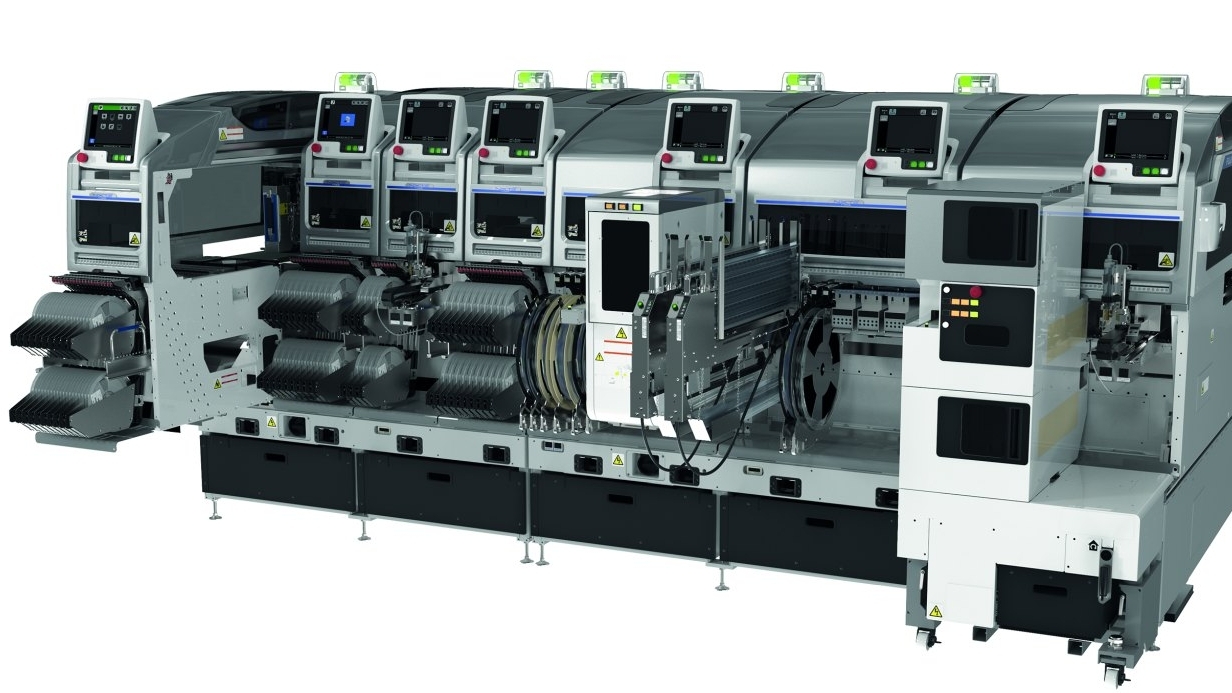

Limtronik already uses 16 modules from the NXT series. The holistic modular approach of the scalable Fuji placement platform offers users the opportunity to configure a machine tailored to their requirements.

"As the time factor is becoming increasingly important, we are now expanding our machine park for our customers with an NXT M6-III module." The third-generation multifunctional modular pick-and-place machine is particularly designed for speed and positioning accuracy. Limtronik also relies on a solution from Fuji for its paste printer: the EMS service provider opted for the GPX-CII because it meets demanding technical requirements at a good price-performance ratio for Limtronik.

Klaus-Peter Kölbel, Sales Manager at Fuji Europe Corporation GmbH, says: "Today, the focus of SMT production is not only on speed but also on quality and accuracy. Success in today's extremely dynamic electronics industry can only be achieved by combining maximum productivity with high quality standards and precision as well as low production costs and short processing times."