Bonding the smallest electronic components with pinpoint accuracy using press-out units is one of ViscoTec's production technology solutions. Festo supplies the pneumatic control module for the current generation of press-out units.

ViscoTec eco-FEED machineTheunits work with double-chamber cartridges. These have the advantage that they can process media such as adhesives, pastes or silicones with different viscosities of the two components. In many bonding processes, the exact mixing of such adhesive components is essential. Both squeeze-out cylinders are moved independently of each other and the correct adhesive mixture is applied to the components to be bonded via a 2-component mixing head. eco-FEED and vipro-FEED DC are the latest devices from ViscoTec for automated, uniform squeezing of double-chamber cartridges.

ViscoTec eco-FEED machineTheunits work with double-chamber cartridges. These have the advantage that they can process media such as adhesives, pastes or silicones with different viscosities of the two components. In many bonding processes, the exact mixing of such adhesive components is essential. Both squeeze-out cylinders are moved independently of each other and the correct adhesive mixture is applied to the components to be bonded via a 2-component mixing head. eco-FEED and vipro-FEED DC are the latest devices from ViscoTec for automated, uniform squeezing of double-chamber cartridges.

Cooperation with adhesive manufacturers

"The right mixing ratios are the result of countless series of tests based on decades of experience," emphasizes Martin Stadler, Managing Director of ViscoTec. The product developers are in constant contact with adhesive manufacturers. "Even before new adhesives are launched on the market, they contact us to run initial tests on our dispensing systems."

The company is also highly regarded in the industry because it not only develops individual devices and components for adhesive application, but also supplies its customers with complete systems. In this way, the cartridge emptying system and the dosing unit, for example, are completely coordinated with each other. Another plus for customers, primarily from the electronics, automotive, aerospace and medical technology, food, pharmaceutical and cosmetics industries, is the advice on the correct use of devices and adhesives or pastes and silicones. "We offer our customers the opportunity to carry out tests for their applications in ViscoTec's laboratories in order to work out the correct mixing ratio and the adhesive quantities to be used with different adhesive viscosities," says Stadler.

Precise adhesive application

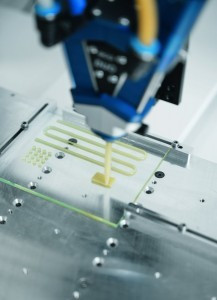

Application example: Application of thermally conductive adhesiveInthe electronics industry, it is important to apply tiny quantities precisely and repeatably to printed circuit boards, for example, or to carry out precise 'gap-filling' on different electronic components - often with highly abrasive, i.e. rough, sharp-edged and aggressive pastes.

Application example: Application of thermally conductive adhesiveInthe electronics industry, it is important to apply tiny quantities precisely and repeatably to printed circuit boards, for example, or to carry out precise 'gap-filling' on different electronic components - often with highly abrasive, i.e. rough, sharp-edged and aggressive pastes.

Correct control and display of the delivery pressure is essential. "In our devices, we rely on a control module with pneumatic automation technology from Festo," says Stadler. It displays and controls the conveying pressure. It was developed in close cooperation with Festo - from the development of the prototype to the current device ready for series production.

Ready-to-install control module

The control module is a ready-to-install assembly that Festo supplies directly to the assembly line of ViscoTec's ejection devices. It monitors the pressure and quality of the adhesive application independently of temperature and viscosity and even enables volumetric filling, one of the specialties. It enables optical fill level monitoring, which is also available electrically as an option.

The module consists of the robust VUWS pneumatic valve, VHER control spools, flange manometers, LR-D pressure control valves, screw fittings, silencers and PUN hoses. Heidinger: "The ready-to-install module supplied by Festo saves us time and effort because we can install it directly and easily into the press-out device and we can rely on the proverbial Festo quality and the worldwide availability of spare parts."

Countless applications

Martin Stadler, Managing Director ViscoTecIn addition toprecise bonding, several 100,000 dosing pumps from ViscoTec have become an integral part of everyday industrial life worldwide, for example for filling cans and tubes for mascara, peelings or skin creams, as well as for dosing and filling fruit into jam jars without clogging them. Adhesive applications 'made by ViscoTec' are characterized by the fact that the high-precision application of the adhesive means that there are no adhesive edges on displays or microcameras, or that no adhesive oozes out of all corners and edges of the bonded components in everyday consumer goods such as coffee machines or radios. "Striving for maximum precision in the processing of viscous media is on our daily agenda and ensures our leading position on the global markets," concludes Managing Director Stadler.

Martin Stadler, Managing Director ViscoTecIn addition toprecise bonding, several 100,000 dosing pumps from ViscoTec have become an integral part of everyday industrial life worldwide, for example for filling cans and tubes for mascara, peelings or skin creams, as well as for dosing and filling fruit into jam jars without clogging them. Adhesive applications 'made by ViscoTec' are characterized by the fact that the high-precision application of the adhesive means that there are no adhesive edges on displays or microcameras, or that no adhesive oozes out of all corners and edges of the bonded components in everyday consumer goods such as coffee machines or radios. "Striving for maximum precision in the processing of viscous media is on our daily agenda and ensures our leading position on the global markets," concludes Managing Director Stadler.

ViscoTec Pumpen- u. Dosiertechnik GmbH is a manufacturer of systems required for conveying, dosing, applying, filling and dispensing medium to high-viscosity media. The headquarters of the technological market leader is in Töging am Inn (Bavaria, near Munich). ViscoTec also has subsidiaries in the USA, China, Singapore, India and France and employs around 270 people worldwide. All media, which in individual cases have a viscosity of up to 7,000,000 mPas, are conveyed and dispensed practically pulsation-free and with extremely low shear force.

Festo is both a global player and an independent family business based in Esslingen am Neckar. Festo has been setting standards in industrial automation technology and technical education since its beginnings, thereby contributing to the sustainable development of the environment, economy and society. The company supplies pneumatic and electrical automation technology for 300,000 factory and process automation customers in over 35 industries.