The Swabian special machine manufacturer Eutect has developed a thermode soldering system for the Luxembourg automotive supplier IEE S. A. that can be used to wire sensor mats for car steering wheels.

Drivers have a wide range of high-quality technologies at their disposal in the interior of modern vehicles. Given the complexity of these systems, manufacturing them is no easy task. Special manufacturing solutions have been developed for the IEE S.A. Hands Off Detection Sensing System (HOD).

HOD technology makes it possible to determine whether a driver is holding the steering wheel while driving - important information for driver assistance systems. For example, according to the UN-R79 regulation, lane departure warning systems must issue a warning if the driver's hands are not on the steering wheel for longer than 15 seconds. Another example is automated driving vehicles. Here, the electronics must be able to clearly distinguish whether the driver is steering the car or the car is driving autonomously.

Special concept for exceptional requirements

The TL S270 integrates five individual processes in line and a complete process monitoring system. The system consists of various individual solder paste application steps using a dispenser and thermode solderingTheHOD technology is based on a 3 mm thin sensor mat that is attached under the steering wheel cover. However, materials such as leather require specific manufacturing processes. This is why the experts at IEE S. A. commissioned the soldering and joining systems specialist Eutect to develop a corresponding machine concept.

The TL S270 integrates five individual processes in line and a complete process monitoring system. The system consists of various individual solder paste application steps using a dispenser and thermode solderingTheHOD technology is based on a 3 mm thin sensor mat that is attached under the steering wheel cover. However, materials such as leather require specific manufacturing processes. This is why the experts at IEE S. A. commissioned the soldering and joining systems specialist Eutect to develop a corresponding machine concept.

"It is important for us to ensure the optimum soldering process for an application. That's why we take a close look at the customer's conditions and evaluate the required performance characteristics on the basis of extensive tests. In the case of HOD technology, we decided on thermode soldering together with the customer," says Matthias Schmid, Project Manager at Eutect.

With the TL S270 multi-thermode system, the experts have developed a highly flexible machine concept that allows all the necessary individual steps to be linked and monitored. Moreover, with a width of 2.3 m and a length of 4.8 m, the TL S270 is one of the largest complete systems ever developed by the soldering specialists.

Five individual processes in line

HOD technology requires sensors with differently positioned cables to be soldered. The complete system was therefore equipped with 2 dispensing and 3 thermode soldering processes. The assemblies are transported within the system via satellite workpiece carriers, which are located on a base carrier. With a length of 1300 mm, the workpiece carriers correspond to the maximum product length.

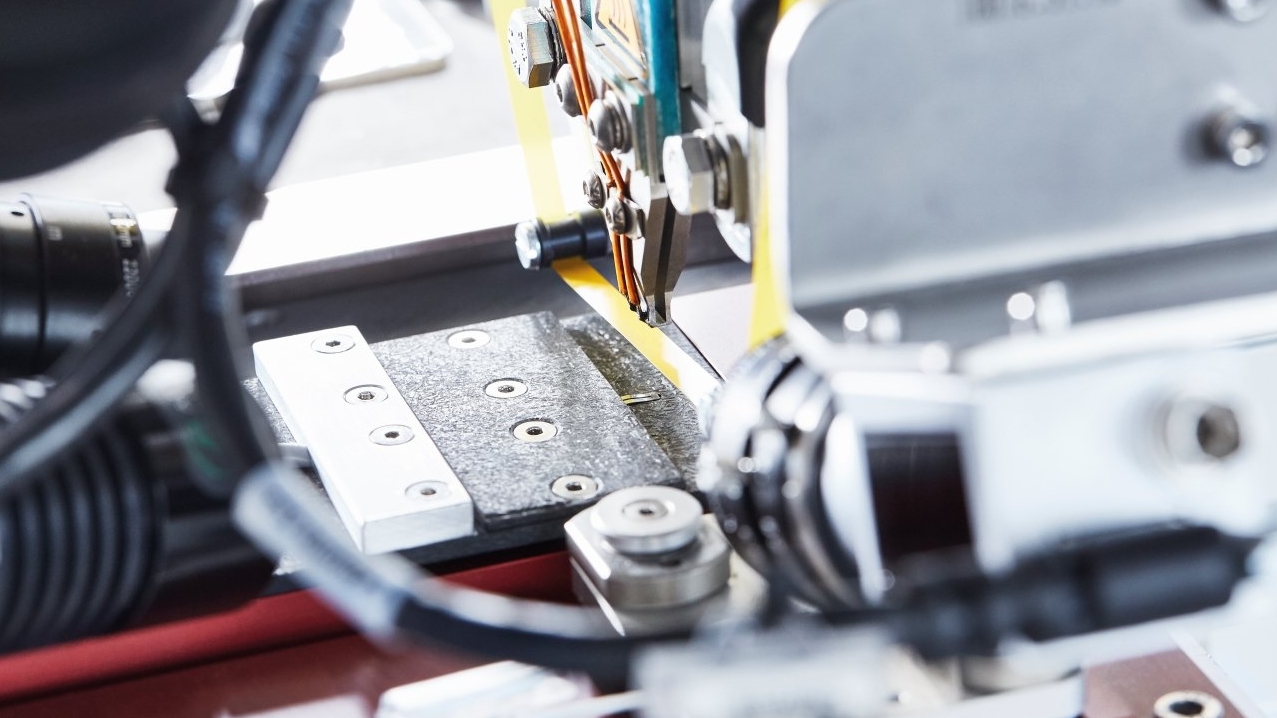

To attach the cables, the sensor is manually inserted into the workpiece carriers. In addition, the cables to be soldered on are placed and fixed in the exact position with the help of other small cable holders inserted by hand. As soon as the workpiece carrier has been inserted into the system, spindle valve dispensers apply solder paste to the assembly surfaces and the cable strands of the cable ends in the first two steps. The strands are then soldered using thermode soldering with temperature, force and distance monitoring. A specially developed alignment aid ensures a repeatable position of the strands and therefore reproducible soldering results.

All process-relevant parameters, such as the contact pressure, the penetration path and the temperature profile, must be able to be defined precisely according to the process and the operator's requirements. The developers have therefore integrated three TL thermode soldering modules that meet current requirements.

The thermode soldering modules are mounted on a 4-axis system X-Y-Z-D (linear axes), whereby the thermode soldering module is equipped with an additional axis (highly intelligent linear motor) for the process infeed.

Contact pressure and penetration distance

The contact pressure of the thermodes is 1-60 N, whereby the contact pressure can be displayed in 0.5 N steps. A visual control view makes it possible to specify a contact pressure to suit the materials and the application. In addition, a leading and trailing hold-down clamp fixes the surfaces to be soldered. "This allows cooling times to be optimized by up to 70 % depending on the heat sink of the solder joint and cycle time savings of up to 20 % to be achieved," emphasizes Schmid.

Another process advantage is the ability to control the sinking path. The penetration control is 1 µm and therefore in a unique range for thermode soldering. The sink-in distance can be freely adjusted in µ, enables a defined soldering gap and thus allows optimum intermetallic phase arrangements. The temperature profile is permanently monitored and regulated by a programmable logic controller.

Smooth return transport

The TL S270 thermode soldering system offers two different process-relevant modes, whereby the assembly is entered manually. As soon as the assembly has passed through the system, it can be removed on the opposite side. Alternatively, it returns to the input position on a conveyor located in the chassis, where it can be removed by the operator.

The machine is also equipped with modules for monitoring and transport safety. For example, there are monitors at the input and rear removal areas that can be used to control and monitor processes. Thanks to the attachment to long arms, it is possible to use the monitors on all four sides of the system. A further monitor is also installed at the entrance area. The dispensing process, which is monitored by two cameras, is displayed here.

Another conveyor belt mounted on the side of the system ensures the smooth return transport of the cable holders within the system. This belt makes it possible to carry out the wire placement process by returning the wire satellite carriers in parallel with the actual soldering process. Otherwise, the cycle time-optimized system would have to wait for the operator.

Enhanced performance for the future

The current focus is on integrating the detection system into car steering wheels. In the future, however, truck steering wheels are also to be equipped with HOD technology. A machine with a track width of 1500 mm is therefore currently being developed. The cognitive assistance system 'Smart Klaus' could also be integrated here to support the workers in ensuring the quality of the complex, manual production steps with a high number of variants.