The functions and performance of SCARA robots have evolved: New designs enable smaller robots to handle larger jobs and achieve high deflection speeds to keep cycle times low. Image processing systems are easier to integrate and simpler to program thanks to plug & play systems. In addition, new functions make it possible to reduce mechanical wear and simplify maintenance. These developments can be illustrated in more detail by taking a look under the hood of today's SCARA robots.

SCARA robots can automate and speed up pick & place and small assembly processes as well as screwing and dispensing. They can also perform functional tests. Like every other process automation technology before them, robots must add value by increasing productivity and reducing costs for their owners. In any industrial project, the project manager must keep a watchful eye on speed and cycle time as well as accuracy, repeatability and reliability to ensure a satisfactory return on investment.

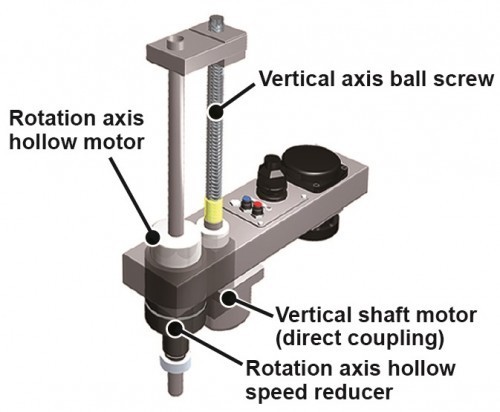

Fig. 1: Completely beltless drives increase precision and longevity

Fig. 1: Completely beltless drives increase precision and longevity

Motion and mass distribution

Innovations to improve the motion control of the robot head help to increase both speed and positioning accuracy. Pick & place processes require perfectly controlled Z-axes (stroke) and R-axes (rotation).

Typically, the movement of the Z-axis is realized via a lead screw driven by the vertical spindle motor, while the R-axis is controlled by the rotary shaft motor via a belt. Both belt drives can be replaced by direct drives that eliminate aging and the risk of belt breakage or stretching, resulting in higher long-term accuracy and reduced maintenance. Yamaha developed a direct ball screw drive for beltless Z-axis control, utilizing its experience with single-axis robots and a combined hollow shaft motor and coaxial reduction gear system that offers several advantages for R-axis motion control (cover image).

In addition to the precise and durable beltless drive, the hollow shaft motor and reduction gearbox enable higher R-axis speeds for high payloads with large offsets. In contrast to a conventional belt-driven R-axis, which has to decelerate when positioning loads with a high moment of inertia, the beltless drive can tolerate a higher moment of inertia as the robot head rotation axis is directly coaxial to the reduction gearbox.

In addition, optimizing the drive ratios helps to achieve the fastest possible speed and x-y movement throughout the machine's working range, resulting in shorter cycle times. This is particularly important for processes where objects are moved over long distances.

The current range of SCARA robots with beltless drive covers sizes up to approx. 1200 mm arm length and approx. 50 kg maximum payload. Smaller models down to approx. 120 mm and a maximum payload of 1 kg enable the user to configure high-performance, space-saving assembly cells that only require a small footprint.

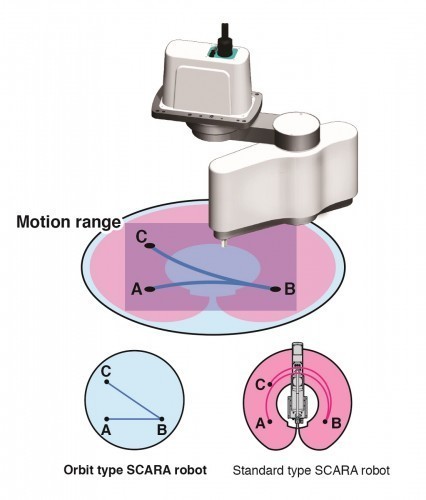

In particularly confined spaces, ceiling-mounted SCARA robots can reach any position within the work area (Fig. 2), minimizing the space required for the process.  Fig. 2: Optimally balanced, ceiling-mounted SCARA robots combine high speed with space savings

Fig. 2: Optimally balanced, ceiling-mounted SCARA robots combine high speed with space savings

With (ceiling-mounted) orbital SCARA robots, optimal weight distribution is the key to high travel speeds with high payload capacity. Yamaha uses lightweight materials and leverages its hollow shaft motor and gearbox expertise combined with optimized internal motor positioning to achieve a standard cycle time for moving a 1 kg load (300 mm horizontal and 25 mm up/down) of just 0.29 seconds, which is approximately 36% faster than previous models. The maximum payload is 5 kg.

Another benefit resulting from better balance and lower inertia is the reduction in the load on the mounting frame that needs to be installed to support the robot. This enables a lightweight, slimline design that saves costs and facilitates installation in the factory.

Innovations optimize system availability

Long-term positioning accuracy and resistance to environmental influences such as moisture, dust and grease can be improved by replacing optical encoders with magnetic resolvers for position sensing. Magnetic resolvers are inherently immune to vibrations and electrical interference that can affect optical encoders. The magnetic resolver benefits from a simple design with few electronic components, which ensures greater reliability and high temperature resistance.

In addition, the consistent simplification of maintenance can make a valuable contribution to increasing system availability. The design of the covers with regard to easy disassembly, without having to disconnect cables or pipes, makes it possible to carry out necessary maintenance or repairs quickly. In addition, the latest long-term formulations of the lubricating greases eliminate the need for time-consuming disassembly and lubrication over the entire service life of the device.

Plug&Play vision system

An optional vision system extends the robot's range of functions to include searching for workpieces and correcting position deviations. In the past, vision was controlled separately from the robot, requiring specialized vision knowledge to program the vision system and use the results for robot instructions. The latest vision systems remove this hurdle and can be integrated into the robot program to enable plug-and-play operation and significantly reduced commissioning time. Communication delays between the vision system and the robot system are also eliminated. Yamaha's iVY2 vision system and RCX340 controller further enhance performance with innovations such as the new CTMOVE command, which executes a complete conveyor tracking cycle from start position to component pick-up, replacing three separate instructions to enable the pick-up and placement of up to 100 parts per minute.

Special requirements

Finally, new configurations can be considered to meet special requirements. The SCARA robots for inverted wall mounting are specifically designed to lift the workpiece from below, which prevents contamination from falling particles such as dust or moisture that may have accumulated on the surface of the robot. SCARA robots are also available as cleanroom robots, which benefit from beltless operation that eliminates contamination from abrasion and helps prevent dust emissions with an integrated suction unit at the rear of the machine.

Conclusion

The design of SCARA robots is continuously being improved in many subtle ways - from the rotary head to the control interface - to increase performance, speed and reliability, enabling higher productivity and a faster return on investment.

Yamaha Factory Automation Section (FA Section), a subdivision of the Yamaha Motor Robotics Business Unit of Yamaha Motor Corporation, focuses on delivering flexible, high-precision industrial robots to meet the challenges of precision automation. The division has its roots in the introduction of robotic technology to Yamaha motorcycle assembly and has more than 40 years of experience in solving automation tasks from large product assembly to micrometer scale. Yamaha's industrial robots are now used by world-leading companies in fields as diverse as semiconductor manufacturing and the assembly of electronic products, household appliances, automotive components and large liquid crystal displays.

Yamaha FA Section offers a wide range of robotic assembly solutions, including single-axis robots, SCARA robots, Cartesian and articulated robots. Innovations such as the LCM100 linear conveyor module, a smooth-running, space-saving and more versatile successor to conventional belt and roller conveyors, continue to set the pace in factory automation. The core robotics technologies as well as key components and complete robot systems are manufactured in-house, which ensures consistent quality and control of delivery times.