The coronavirus pandemic has taught us how vulnerable long supply chains and poorly automated production processes are. This article uses examples to show that robot manufacturers are ready with a growing range of services to advance the level of automation in the electronics industry. The governments of leading industrialized countries are supporting the robotization of factories through numerous funding programs.

The coronavirus pandemic is weakening the global economy. There are several reasons for this, e.g. temporary production stoppages as a direct result of the pandemic, interrupted supply chains and limited availability of labor. One of the conclusions that is emerging, especially in the 'Western' industrialized countries, is to shorten supply chains where possible by bringing the production of supplies from low-cost foreign countries back to the vicinity of the final producers (re-shoring). Since these supplies usually come from countries with lower wage levels, the issue of higher labor costs must be sensibly clarified when re-shoring for reasons of competition.

Another insight from the coronavirus pandemic is that the more people involved in production, the more vulnerable it is. They can fall ill themselves or be sent into quarantine or short-time working. For the sake of completeness, it is worth mentioning the nationalistic mindset of relocating production facilities back to China, as the Trump administration is increasingly demanding of US companies with production facilities in China.

More automation

A growing number of companies are therefore attempting to see the crisis as an opportunity to convert or modernize their production and make it even more flexible. The aim is to increase automation on the one hand and reduce the number of employees on the other. At best, production can be increased with the same number of employees, but at lower cost and with greater flexibility.

Industrial robots as an important instrument of automation have several advantages for companies: Firstly, they do not get sick and are not infectious, and secondly, they often work more precisely and with greater endurance than humans, which can ultimately also help to reduce costs. In the electronics industry in particular, the advancement of miniaturization means that the demands on precision are increasing and the uniformity of the execution of work operations is also constantly growing (Fig. 1).

The International Federation of Robotics (IFR) has predicted that around two million new industrial robots will be installed in factories worldwide between 2020 and 2022 [1]. These estimates were made shortly before the start of the coronavirus crisis. Some experts assume that re-shoring will intensify as a result of coronavirus. For this reason and due to the general increase in automation, demand for robots will rise even more significantly in the medium term than in 2019 - ultimately much more than predicted by the IFR. If, for example, many US companies that previously produced in Southeast Asia on the basis of much lower wages really do give in to pressure from the US government and the changed market conditions caused by coronavirus and relocate production back to the US, this will only make sense if drastic automation is used to more or less transition to the 'human-free factory'. This in turn implies even more use of robots.

The IFR outlined that the following three trends will accelerate the advance of robot technology in production:

- Easier robot integration, because programming and installation of robots will become much simpler, for example through automatic learning programs. The latter guide robots to optimize their movements using trial-and-error methods and work with video demonstrations

- Robots work directly with humans (collaborative work). Modern robot systems can be quickly adapted to changing conditions in a shared workspace

- Industrial robots are becoming part of digital networks. They are a central component of digital and networked production in the sense of Industry 4.0, making it all the more important that they can communicate with each other - regardless of the manufacturer. The so-called 'OPC Robotics Companion Specification', which was developed by a joint working group of the VDMA and the OPC Foundation, defines a standardized generic interface for industrial robots and enables the connection of industrial robots to the IIoT

The digital connectivity of robots, for example with the cloud, is also a driver for new business models. According to IFR, robot leasing - known as Robots-as-a-Service - has advantages that could be particularly attractive for small and medium-sized enterprises (SMEs): no capital commitment, fixed running costs, automatic upgrades and no need for qualified personnel for the robots.

"We see the need for greater, intelligent and effective automation in electronics manufacturing ..."

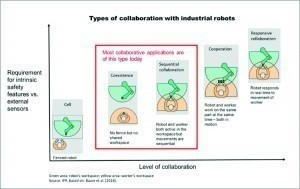

In Figure 2, the IFR demonstrates the development stages or types of collaborative work between humans and robots. The predominant way in which they now work together (red box) is that both work in the same workshop, but with separate workspaces, or that both have a common workspace but proceed sequentially. The right-hand graphic area, where robots and humans work together collaboratively, is only in the early stages. Fig. 2: Stages in the development of robot and human work towards collaborative activity

Fig. 2: Stages in the development of robot and human work towards collaborative activity

Growing activity in the German robotics market

Various press releases in recent weeks indicate that both robot manufacturers and their sales partners are increasingly concerned about what the industry will do after coronavirus. It seems that they are preparing for an accelerated market development and are offering more products in the direction of greater automation than before. They are clearly including the electronics industry in their considerations and strategies. The proportion of robots that are also suitable for use in the electronics industry or have been specially designed for it is growing. Three different examples of this are presented below.

Hilpert electronics AG

The Swiss company Hilpert electronics AG, based in Dättwil, Eichenau, provides consulting, production equipment and consumables for the development and production of electronics, microelectronics and micromechanics. The company announced in May that it has added Taiwanese robot manufacturer Techman Robot Inc. as a new product supplier to its program. With this step, the Swiss sales organization in the electronics industry is expanding its product portfolio to include robotics. The initial aim is to establish Techman Robot's collaborative robots in Swiss electronics manufacturing. Other industrial sectors would then follow in the course of the summer. The special feature of these collaborative robots is that they can work in close proximity to and together with humans thanks to their integrated sensors.

As Hilpert's German subsidiary in Eichenau offers the same range of services, it can be assumed that the Techman robots will also be introduced here. The Swiss clearly indicate that the latest decision is of strategic importance to them.

"As Hilpert AG, we are consistently working on a future orientation that clearly focuses on the challenges facing the electronics industry in Switzerland in the coming years," said Raphael Burkart, Managing Director of Hilpert electronics AG. Derived from this orientation, the inclusion of a collaborative robot solution in the product portfolio was the logical step. "We see a need for stronger, intelligent and effective automation in electronics production that our customers can use flexibly for a wide range of tasks."

Hilpert offers four robots in two categories. The TM5-700 and TM5-900 systems are smaller robots with a reach of 700 and 900 mm respectively and a payload of 4 and 6 kg (Fig. 3). The TM12 and TM14 are two further robots in the portfolio that enable reaches of up to 1300 mm and a payload of up to 14 kg. All robots are equipped with an integrated camera system that allows them to recognize their position, set their own coordinates and perform visual tasks. Furthermore, all systems can also be used in different positions within a production facility. For this purpose, the robots are mounted on a transport trolley and moved to their respective work positions. Fig. 3: Example of the use of the TM5-700 robot from Techman in an assembly line in the electronics industry

Fig. 3: Example of the use of the TM5-700 robot from Techman in an assembly line in the electronics industry

Thanks to the flexible integration of grippers and peripheral devices from a wide range of manufacturers, the collaborative robots can be used for a wide variety of applications. Thanks to the integrated hardware interfaces, the Plug&Play software makes it easy to use additional tools. The robot programming software TMflow is used to define the robot's respective tasks. The individual steps of the task can be put together easily and intuitively thanks to the drag-and-drop handling.

The operating system in the TM5-700 controller is based on Windows. This means that the same user interface can be installed directly on the TM5-700 as on a remote PC. The individual function blocks are dragged and dropped into the flow chart and then set up. The camera can also be set up in just a few minutes. The robot base module with its six rotation axes weighs 22 kg. The repeat accuracy of +/-0.05 mm is sufficient for many applications in electronics assembly.

"We see a wide range of applications for the robots from Techman Robot in the electronics industry," says Ralf Jentscher, Sales Manager and Consultant Robotic at Hilpert AG. For example, the robot can use a gripper to place assemblies in ESD packaging, insert larger THT components and connectors into circuit boards or use suction systems to insert and remove assemblies in test systems. Active production steps are also possible. For example, housing screws can be tightened with a screwing tool, components can be soldered with a soldering iron or adhesives, seals or potting compounds can be applied using a dispenser. Visual examples of this can be found at [3]. Figure 4 symbolically demonstrates the wide range of applications. Fig. 4: Application suggestions for TM5-700

Fig. 4: Application suggestions for TM5-700

A press release from March of this year shows how intensively the Taiwanese are approaching the European market, even during the coronavirus pandemic. In it, Techman announces that it has opened its first European branch in Alblasserdam, the Netherlands.

The company's strategists are clearly thinking in terms of Industry 4.0. For example, Techman Robot's TM Smart Factory is a software-based factory management solution that paves the way for the complete digitalization of production facilities. It is designed to optimize production management in factories where the data from collaborative robots and the data from the entire plant was not previously collected, monitored and managed.

Universal Robots

The Danish company Universal Robots was founded in 2005 by three students in Denmark and was the first company to produce commercially viable collaborative robots. The US company Teradyne acquired Universal Robots in 2015, giving it a market share of 50% and 65 patents. Here, too, it has been understood that coronavirus is triggering new automation strategies at a growing number of companies. Accordingly, the company announced in mid-May that it was expanding its sales network in Germany with four new partners: Glaub Automation & Engineering GmbH, ID Ingenieure & Dienstleistungen GmbH, Samsys GmbH and Stadler GmbH & Co. Elektro KG further [4]. The selection of these companies was by no means random.

"It is our aim to further strengthen the partner network in order to pave the way for companies of all sizes to automate with our cobots. German SMEs in particular are currently developing a new awareness of collaborative robotics and the wide range of possible applications. In this situation, a reliable network is the key to success - for us, our partners and our customers," says Helmut Schmid, Managing Director of Universal Robots (Germany) GmbH and Regional Sales Director for Western and Northern Europe.

The four new partners of the Danish robot manufacturers mentioned show certain differences in their fields of activity. Glaub Automation & Engineering GmbH is a company based in Germany and Hungary that specializes in automation and software services. For them, the partnership with Universal Robots is an important opportunity to expand their offering for the automotive, household appliances and healthcare sectors. Glaub not only wants to realize THT assembly, small parts assembly and test stations for major customers, but also implement automation for SMEs in the areas of handling and application/dispensing with UR cobots. The solution is: automate faster with certified UR+ application kits and components (Fig. 5). Fig. 5: Basic module of the UR3 robot from Universal Robots

Fig. 5: Basic module of the UR3 robot from Universal Robots

ID Ingenieure & Dienstleistungen GmbH has a slightly different approach. It develops machines and systems for the packaging industry and the consumer goods sector and specializes in special machine construction. They see collaborative UR robots as an important component in the production of the future.

Samsys GmbH is an expert in loading and unloading systems. It offers standard and special solutions to enable the optimum path to automation in each case. The company only accepts equipment that is well designed and characterized by ease of operation, quick changeover, reliability and durability. These are all arguments that are also of interest for electronics production.

Stadler GmbH & Co. Elektro KG has a broad range of applications - with automation solutions based on lightweight robots for the food, logistics, pharmaceutical, metal, electronics and automotive industries. In addition to conventional robot applications, the company is now tapping into collaborative robotics.

Universal Robots focuses on system solutions for its robots, i.e. together with partners, interested parties are offered UR+ application kits. They simplify the fastening and connecting of components or other objects in the production process. An example of this is the Dahl Dispensing Kit (Fig. 6). Fig. 6: Symbolic representation of the Dahl Dispensing Kit

Fig. 6: Symbolic representation of the Dahl Dispensing Kit

The UR-Cobot family, in which each robot has six joints, offers four different options with load capacities of 3, 5, 10 and 16 kg. This means that a wide range of applications can be covered. The UR3e, the smallest cobot in the series, can be used for many tasks in the electronics industry. Thanks to its small footprint, the ultra-lightweight collaborative table-top robot is particularly suitable for installation in systems or confined working environments. The Cobot weighs just 11 kg and has a payload of 3 kg. It requires a base area with a diameter of 128 mm. The working radius is 500 mm. The e-Series Cobot System package includes all the connectivity, communication and functionality solutions of the e-Series platform: I/O, network, USB, peripheral connections, safety settings, etc. You can choose between DC and AC models to match the user's power supply.

Since all of its joints can rotate 360 degrees and its 'wrist' can rotate without limits, it handles high-precision assembly and screwdriving work with ease (Fig. 7). Fig. 7: UR3e Cobot in practical use

Fig. 7: UR3e Cobot in practical use

"Every country has its own characteristics of robot programs ..."

A decisive factor for robot use is the repeat accuracy of the working head [5]. The 7-part cobot series from Universal Robots (UR3, UR5, UR10, UR3e, UR5e, UR10e, UR16e) differs not only in its different working radii (500-1300 mm) and load capacities (3-16 kg), but also in its different repeat accuracies. The latter ranges from +/- 0.03 mm to +/- 0.1 mm.

Yaskawa

Yaskawa is also strengthening its presence in Germany, especially as the range has been expanded to include smaller robots and cobots suitable for electronics production since 2019. The author was not told about this when he visited Yaskawa in Kita-Kyushu in 2017. In general, the Japanese are now aiming to make their own growing capabilities even more visible [6].

The Japanese company is launching a range of robots on the market that are optimized for various applications, including welding, handling, component assembly, painting, LCD panel and semiconductor wafer transfer. This is also Yaskawa's response to the growing demand for automation in Japan resulting from the increasing labor shortage. The company says it is time to use robots to improve productivity and reduce manufacturing costs in industries other than the automotive industry. In April this year, for example, Yaskawa announced that the Group is involved in the Technology Academy at the Deutsche Messe trade fair in Hanover. The manufacturer of MOTOMAN industrial robots is supporting the Robotation Academy as a new technology partner and is now represented there with its own platform. Obviously, the presentation opportunities already available at Yaskawa Germany are no longer sufficient for the market objectives being pursued. The manufacturer will be exhibiting new robotics trends and current models, including an HRC-capable MOTOMAN HC10 hybrid robot, on around twelve square meters in the Technology Academy pavilion in the center of the exhibition grounds. Four live demo and training cells offer a wide range of opportunities for customer events, workshops and training courses.

At the end of 2019, Yaskawa presented two new types of horizontal robots with a cylindrical workspace (Scara type) from the MOTOMAN SG series. The MOTOMAN-SG400 can be loaded with a maximum of 3 kg (reach 400 mm), the MOTOMAN-SG650 with 6 kg (reach 650 mm). Figure 8 shows the basic modules of the two robots. Fig. 8: Basic modules of the new MOTOMAN SG400 and SG650 robots for the electronics industry

Fig. 8: Basic modules of the new MOTOMAN SG400 and SG650 robots for the electronics industry

The high-speed robots with a very high repeat accuracy of 0.01 mm are particularly suitable for high-precision pick & place tasks such as SMD assembly as well as for adhesive/solder paste application and component feeding. In certain cases, they can therefore be very good flexible alternatives to conventional placement machines with a linear XYZ traversing system, but they are incomparably more flexible than the latter. The relatively low weight of 14 kg makes it easy to change the application configuration.

In May 2020, Yaskawa presented Semistar-Gekko MD124D, a special handling robot for the transfer of semiconductor wafers, which is characterized by high positioning accuracy, low vibration and suitability for clean rooms.

Government programs for robots

From the operational to the governmental levels: The fact that the importance of the increased use of robots together with AI, 5G and Industry 4.0 is understood by the governments of the world's leading industrialized countries can be seen in a press release from the IFR dated June 5, 2020 [8].

It states: The corona crisis underlines the important contribution that robots make to industry and society. Research funding programs (R & D) are crucial to enable and further support these developments. In this communication, the IFR summarizes the national funding programs in the new 'World Robotics R & D Programs'. It examines the objectives of government research funding programs in Asia, Europe and the Americas related to artificial intelligence, big data and 5G.

"Each country has its own characteristics of robotics programs based on its specific background and history," said Prof. Dr. Jong-Oh Park, Vice Chairman of the IFR Research Committee and member of the Executive Board. "Therefore, we see that robotics programs established by the most advanced robotics countries have a very different strategic focus."

In [8], principles of government-backed robotics programs are outlined for the following countries:

- China: Strategic Plan Made in China 2025

- Japan: New Robot Strategy in Japan

- South Korea: The Intelligent Robot Development and Supply Promotion Act

- EU: Robotics Projects funded by Horizon 2020

- Germany: Robotics Projects funded by Horizon 2020 and High-Tech Strategy 2025

- USA: The National Robotics Initiative (NRI)

Finally, a figure is needed to demonstrate why robot manufacturers and dealers are so interested in the German market: Germany is the fifth largest robot market in the world and number one in Europe, followed by Italy and France. In 2018, the number of robots sold rose by 26% to almost 27,000 units - a new all-time record. It is quite likely that this record will be broken in the next two years.

References:

- https://ifr.org/news/top-trends-robotics-2020/

- www.hilpert.ch, www.hilpert-electronics.de/

- www.tm-robot.com/en/industry/

- www.universal-robots.com/de/

- www.jugard-kuenstner.de/universal-robots/cobots-ur3-ur5-ur10-ur16/ur3/

- www.yaskawa.de/header-meta/news-events

- www.yaskawa-global.com/newsrelease/product/25911

- https://ifr.org/ifr-press-releases/