In collaboration with Ascom DACH, the EMS company Limtronik has developed and installed a solution that, for example, automatically displays faults and failures on a mobile basis and supports predictive maintenance processes.

Industry 4.0 thrives on networking and communication. The electronic manufacturing service provider Limtronik GmbH from Limburg/Lahn has been implementing this in its smart factory for several years. Now the company has also raised its internal communication system to a new level.

Limtronik is not only an expert in EMS, but also a Joint Development Manufacturing (JDM) partner. The portfolio ranges from product development support to manufacturing and after-sales service. The company accompanies its customers from product development to the final product ready for series production. The company focuses on the development and production of electronic assemblies and customized systems for customers. Limtronik operates in compliance with Industry 4.0 and is a member of the I4.0 initiative SEF Smart Electronic Factory e. V.

"In our electronics factory, we provide the environment for the Industry 4.0 research and development platform of SEF Smart Electronic Factory e. V. Here, the association develops solutions that pave the way for SMEs and corporations into the digital future. As a result, we are always using the latest Industry 4.0-compatible solutions and standards ourselves," explains Gerd Ohl, Managing Director of Limtronik GmbH.

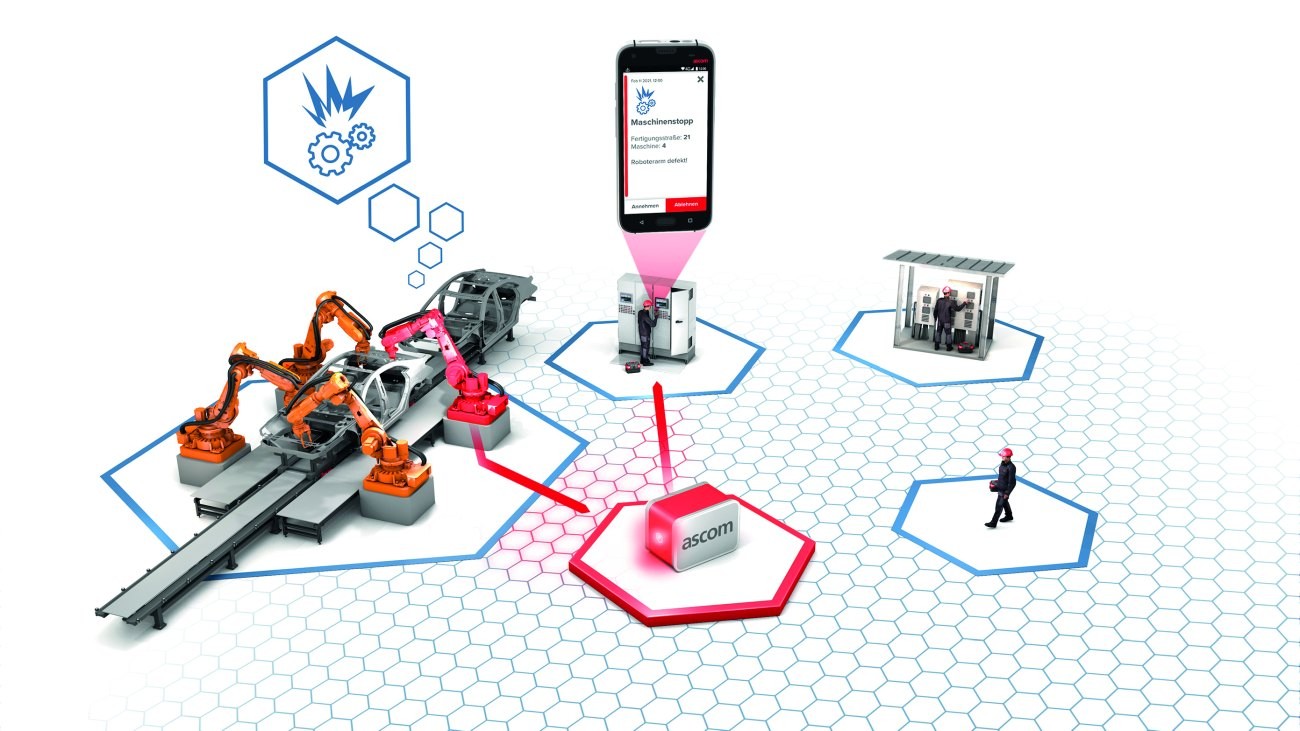

The graphic explains how the Ascom solution works using an automotive example

The graphic explains how the Ascom solution works using an automotive example

Detecting and preventing faults more quickly

Limtronik relies, for example, on linking classic automation technology with applications in the cloud, such as the visualization of machine statuses to mobile employees on the store floor.

Limtronik relies, for example, on linking classic automation technology with applications in the cloud, such as the visualization of machine statuses to mobile employees on the store floor.

floor. An analysis app in the cloud provides the Ascom smartphones with the necessary information to take preventive action in the event of errors or alarms, but also in the event of impending failures.

Limtronik has now put a new communication solution into operation for this purpose. It supports mobile voice communication for employees as well as a personal emergency signal system for lone worker protection (dead man's switch).

Furthermore, text messages about machine statuses or problems with a stored escalation workflow, e.g. increased power consumption in the sense of predictive maintenance, can be forwarded easily and fully automatically on the move.

The solution is connected to the MES (Manufacturing Execution System). This connection supports the recording of error frequencies and material waste in the production process and much more. Thanks to the connection to the building infrastructure, compressed air, heating, cooling system, failures (e.g. weather-related) and faults etc. can be checked - and a direct fault message is sent to the DECT (Digital Enhanced Cordless Telecommunications) telephone.

"The new solution simplifies the communication channels in the company and we are further increasing the efficiency of our smart processes," explains Gerd Ohl.

Limtronik has been manufacturing electronic assemblies and devices since 1970. Limtronik GmbH was founded in 2010. The philosophy of the IATF 16949-certified company is to meet all customer requirements flexibly, reliably and individually.