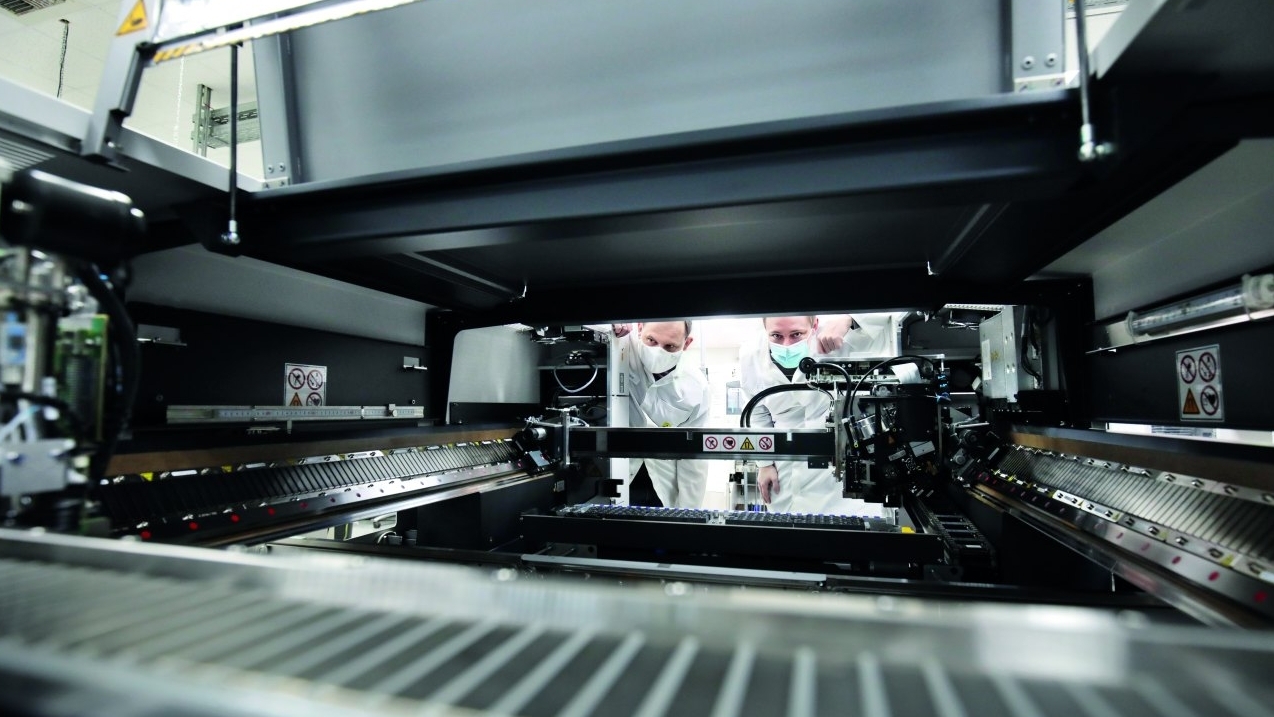

Small component processing with a great future: one of the new ASM SX2 pick-and-place machines is inspected at Lacroix

The trend towards component miniaturization is causing headaches for developers and EMS service providers alike. The use of parts with a barely visible size - such as 01005 - has fallen short of expectations in component production. Now an EMS company is having success with such miniature components in series production - thanks to new special placement machines.

Achieving accuracy of fit in volume production means technical intervention in the overall manufacturing process

Since spring 2021, the German Lacroix Electronics GmbH, a plant of the largest French EMS service provider, has found a way to reliably manufacture assemblies with such components in higher quantities. According to Peter Sommer, Sales Manager at Lacroix, the trend is towards "increasingly compact assemblies". The current designs, on the other hand, will disappear sooner or later. The electrical engineer sees the reason for this in the increasing electronic multifunctionality of devices, which makes a more compact design of the assemblies essential.

Matthias Holsten, change consultant for the electronics industry, sees the integration of components of the extremely small designs mentioned above into series production as critical in three respects: "Achieving a precise fit in volume production means technical intervention in the overall production process. Getting the right solder paste application is precision work, as is the exact picking and placing of the barely visible components, not to mention the extremely delicate soldering process itself. Achieving process reliability is the real problem." In his opinion, many EMS manufacturers are therefore still reluctant to upgrade and convert their machinery and are putting it off. According to Holsten, however, production will soon become uneconomical for EMS manufacturers who "don't jump on board in time".

Lacroix Electronics therefore wanted to introduce the use of miniature components in series production with new units. Since the beginning of February this year, four new ASM SX2 pick-and-place machines have been working in series production. The shorter set-up times that can now be achieved have already brought Lacroix immediate benefits - particularly in the increasing production of prototypes on the series systems. This means that important findings for series producibility come to light at a very early stage. This is a significant advantage, especially when processing small and very small components on the SX2.

Miniature components react very sensitively to incorrect or critical footprints. The integration of the 'Valor NPI' software tool from Mentor has significantly reduced the error rates during assembly. It is an automated design-for-manufacturing flow (DFM) that serves as an early data check in the layout phase. This enables Lacroix to bring products to market faster with efficient PCB assembly.

The situation is similar for solder paste printing with the integration of the Parmi SPI (Solder Paste Inspection) inspection device. During the first work step in the assembly process, the inspection of the paste application, some of which is microscopic, ensures that defects are detected almost completely before assembly and that the components, some of which are expensive, are not lost.

Poor printing that is not detected or only detected after soldering means more rework. The integration of the new SPI and also the new AOI unit from Parmi is proving to be helpful in this respect: as the requirements for soldering smaller components are also considerably higher, the necessary precision cannot be achieved with older devices, according to Lacroix's experience.

The EMS service provider is very satisfied with the results of the technical innovation, as the implementation of the ASM placement machines has already led to new customers. For Sommer, it is clear that the shorter placement and changeover times have led to a noticeable improvement in cost-effectiveness and that the company is therefore "well positioned to compete".