The use of selective soldering systems in electronics production has increased considerably. The driving forces behind this development include the standards introduced by the EU as the WEEE regulation (Waste Electrical & Electronic Equipment) and the Restriction of Hazardous Substances (ROHS). These standards have significantly tightened the requirements for electronics manufacturers.

Areas of application

The Mini-Wave measuring device for data acquisition in the preheating and soldering zoneSelectivesoldering is an important process for soldering wired components on mixed surface mount technology (SMT) assemblies. The alternatives to this would be either manual soldering by production employees or an additional pass through a wave soldering system after reflow soldering has already taken place. Logically, the latter is not necessary for PCBs assembled on both sides. Selective soldering is used when larger components, power components and larger plug connections are to be applied to SMT assemblies. Examples of this are applications in medical electronics, automotive technology or systems for aviation and military technology. In selective soldering processes, care must be taken not to thermally damage the surrounding components, as otherwise the already soldered connections could come loose. Precise process controls are therefore necessary at this stage of production to ensure that all thermally induced product specifications are reliably met in this step.

The Mini-Wave measuring device for data acquisition in the preheating and soldering zoneSelectivesoldering is an important process for soldering wired components on mixed surface mount technology (SMT) assemblies. The alternatives to this would be either manual soldering by production employees or an additional pass through a wave soldering system after reflow soldering has already taken place. Logically, the latter is not necessary for PCBs assembled on both sides. Selective soldering is used when larger components, power components and larger plug connections are to be applied to SMT assemblies. Examples of this are applications in medical electronics, automotive technology or systems for aviation and military technology. In selective soldering processes, care must be taken not to thermally damage the surrounding components, as otherwise the already soldered connections could come loose. Precise process controls are therefore necessary at this stage of production to ensure that all thermally induced product specifications are reliably met in this step.

Wired components

Wired components are also applied to many mixed assemblies. There are different methods of selective soldering technology to meet the specific requirements of the solder joint on these complex boards and the immediate component environment. These range from systems in which the component connections are briefly immersed in liquid solder to programmable mini wave soldering systems. Selective, lead-free soldering of wired components with the higher temperatures required here has several advantages over other processes, such as conventional wave soldering. Components and circuit boards are exposed to shorter thermal contact, minimizing the likelihood of thermally induced damage. The reliability of the circuits can therefore be optimized.

Mixed assembly

Mixed boards manufactured using the wave soldering process require specifically designed solder frames or solder masks. However, plugged or double-sided SMT assemblies and some wired components cannot generally be soldered on such systems due to their complexity. In addition, such special soldering frames are often complex and cost-intensive, which is why they are generally not used. If it is not possible to run a mixed assembly through a wave soldering system, it is possible to solder the wired parts manually. However, this process step can deliver very different and unreliable results depending on the employee, which is why the rework effort is often higher here. As a general rule, manual soldering should be avoided in the production of high-reliability systems. In order to eliminate such imponderables, selective soldering systems with precisely reproducible results were ultimately developed for industrial production. SolderStar has developed a comprehensive range of special temperature profile measuring systems for this constantly growing application area. These instruments, which meet the highest standards of accuracy and reproducibility, continue to be developed and refined in close cooperation with existing users.

Detailed testing possible

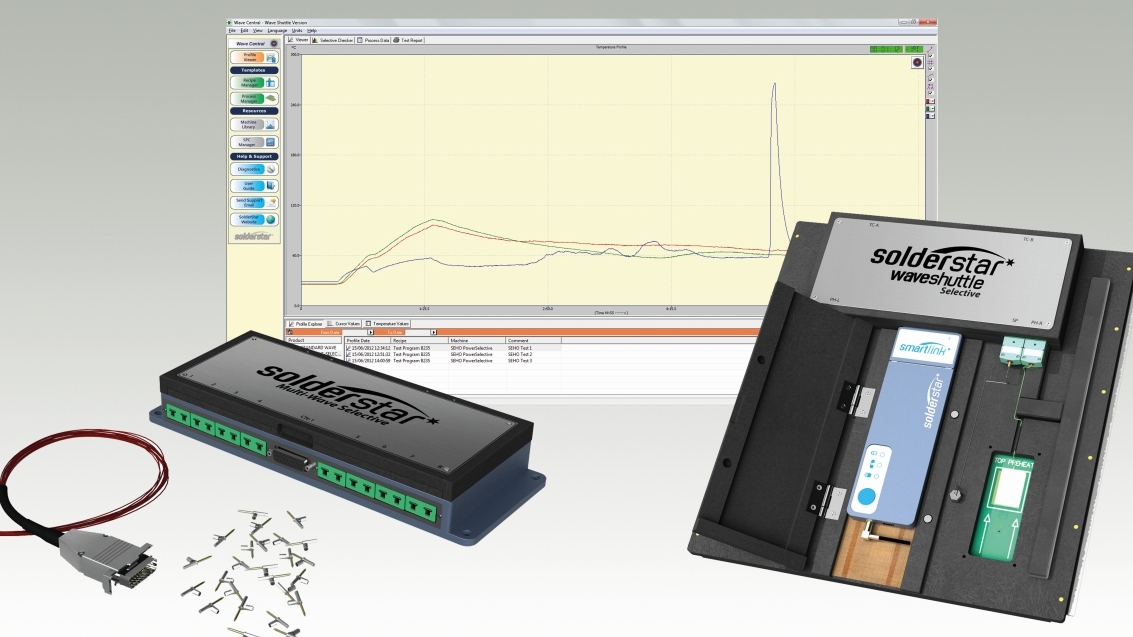

In addition to these innovations, a temperature sensor for preheating and a measuring probe for the solder temperature have been added. This means that all key parameters can be recorded in a single pass through the system. The WaveShuttle Selective system from SolderStar is therefore the preferred tool for setting up and continuously monitoring mini wave soldering systems. The outstanding feature of this solution is the specially configured array of titanium solder wave contact sensors on the underside of the measuring system, which allows detailed checks of the system functions to be carried out quickly, comprehensively and easily.

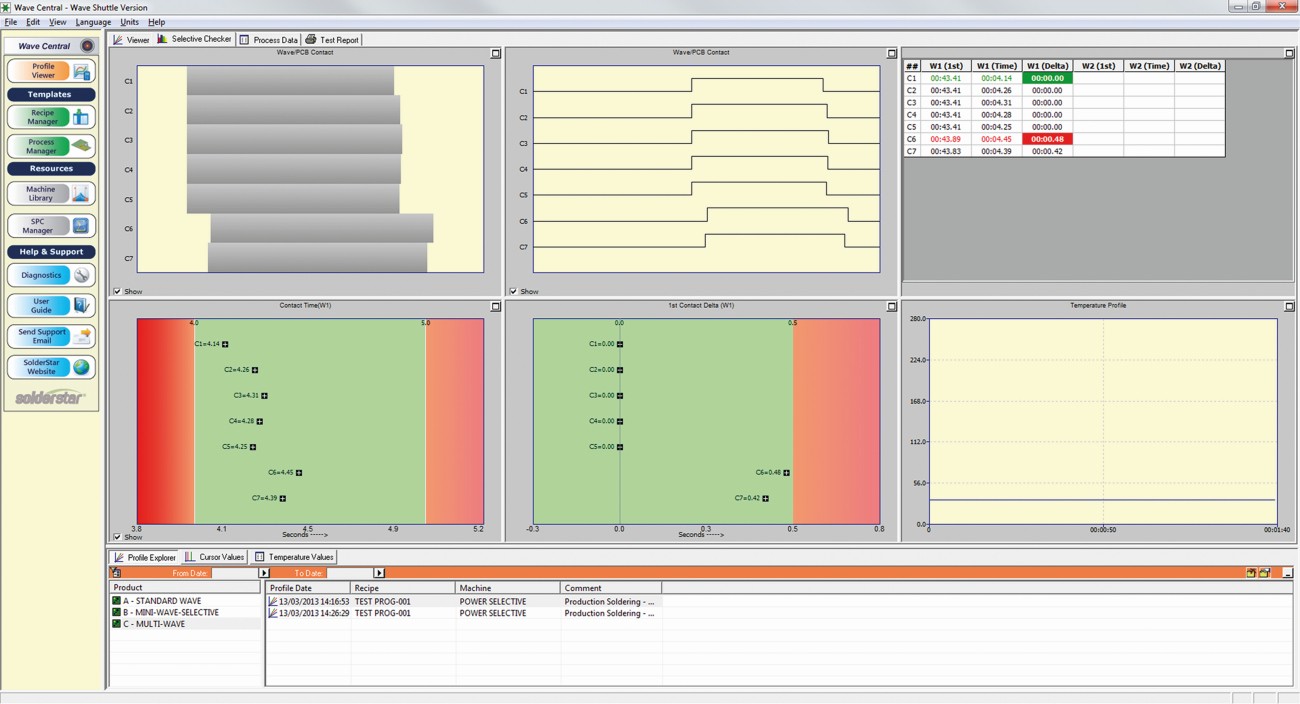

Analysis of a printed circuit board with the Multi-Wave software to assess the effect of a nozzle shape in the system

Analysis of a printed circuit board with the Multi-Wave software to assess the effect of a nozzle shape in the system

Solder nozzles that mistakenly touch the components on the assembly, whether due to deflection of the PCB or excessive manufacturing tolerances, can lead to faults in the positioning mechanism. The positioning of the SolderStar WaveShuttle Selective in the X and Y axes as well as the axis speed is checked by moving the solder nozzles within defined reference points in the setup. The solder wave heights can be recorded and periodically checked at the nozzles using a series of stepped contact sensors. Another problem reported by electronics manufacturers is crystallization effects in the flux nozzle. These can be the cause of incorrect flux application, which then results in insufficient wetting or non-activated flux residues. SolderStar has taken precautions against this and developed special measuring sensors for the flux as an option. This allows the flux application and its position to be precisely recorded as part of the continuous tests. All soldering parameters can be quickly examined on the basis of the predefined good/bad criteria, thus enabling continuous process controls without the need for detailed specialist knowledge. The system offers a number of important advantages in process control:

- Verification of speed and positioning of the XY axes

- Measurement of the plumb line height at the nozzle

- Robust titanium sensors

- Optional: Additional sensor for measuring the flux application

- Temperature sensors for preheating and solder wave

- Customized soldering widths and sensor positions for lines with individual working widths or for special applications.

Multiwave technology

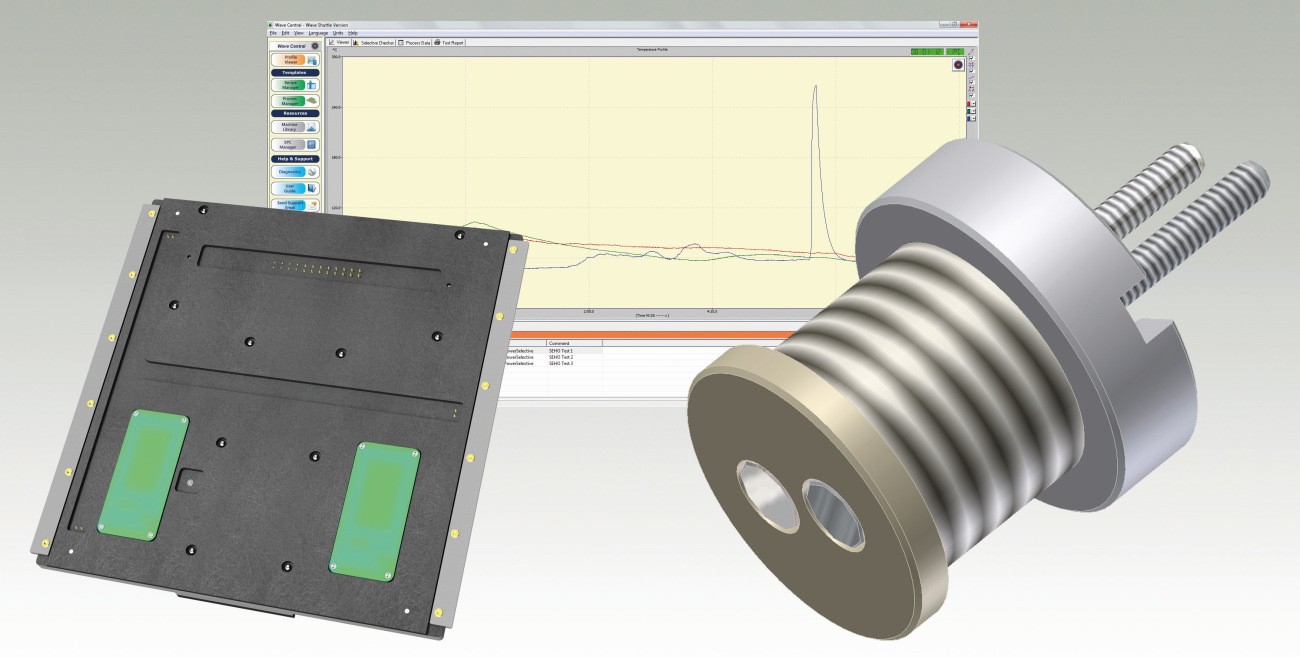

Another important role in selective soldering is played by multiwave technology. The focus here is clearly on greater flexibility, not the maximum achievable throughput. With this type of machine, application-specific covers are required, with which the solder is selectively available only at the relevant soldering points for a short dipping process. A different approach is required to analyze this soldering process, as process engineers need their own sensor configurations to take into account the individual designs of the covers used. The SolderStar Multi-Wave PRO offers a compact and flexible solution for this. The ability to flexibly align the measurement configurations specifically to the respective process enables quick and cost-effective testing of multi-wave soldering systems. The measuring sensors are attached to the specific positions according to the component arrangements and thus correspond to the soldering area and the areas defined by the mask.

Soldering technology

This enables technicians to immediately identify problems in an area of the soldering process, e.g. blocked nozzles, missing or too short contact times or even problems with masking. All this data is immediately available. The measured contact times and temperature differences enable precise fault analysis. This provides users with a powerful platform for analyzing process capability, for possible optimizations and for ongoing checks. The main features of this system are

- Flexible design to adapt the measuring system to different requirements

- Recording the contact times of the solder nozzle and solder joint

- Height of the solder at the nozzle/immersion depth

- Time difference to first contact

- Temperature profile of the preheating zone

- Temperature in the solder pot

- Recording the heating rates.

Accurate measurement results thanks to high-speed measurements

The speeds of the XY axes in selective soldering systems can be very high. Accurate and reliably reproducible results can only be achieved with a fast-reacting measuring system. In the SolderStar system, the contact sensors record the data in steps of 10 ms, with the digital measurement technology ensuring extremely accurate results. The innovative solder contact measuring system requires a reliable ground connection to the machine, but there are mini wave soldering systems with limited ground conditions. SolderStar's solution is to provide a special ground connection directly next to each measurement sensor to ensure repeatable, accurate measurement results. Such measurements and verification of data are of paramount importance for a precise soldering process. Manufacturing electronic assemblies without precise knowledge of the thermal soldering profile would be absolutely counterproductive: after all, how can you monitor and control something if you don't even know what it is? This rhetorical question already shows how critical such an approach would be in industrial production. For example, changes can occur in the preheating, settings can be changed by mistake or deposits can accumulate on the solder nozzles. If the solder nozzles do not wet the assembly precisely during soldering, either due to PCB bending or incorrect machine settings, deviations in the XY axes can occur and the soldering process is not carried out correctly.

Flux sensor on wave measuring board for monitoring the job

Flux sensor on wave measuring board for monitoring the job

Programmed routine movement

A routine movement is programmed in the SolderStar system for the XY speed measurements, in which the sensors X1 and X2 are moved quickly. The recorded time is then used as the basis for calculating the speed. The sensors have a diameter of only 1 mm and can be easily mounted on an individual measuring device. It can be determined that all measurements at the preheating points and at the solder nozzles are accurate. The measurement of the solder wave only has a small tolerance of 0.1 mm.

Flux application - the challenge in the selective soldering process

The fluxer facilitates the soldering process by both cleaning the component connections and preparing them for soldering by wetting them. For reliable soldered joints, the component connections must be free of dirt, oxides and/or oil residues. This is ensured by the flux. The flux is applied using the jetting method, in which tiny droplets of flux are quickly sprayed onto the solder joints. Only the prepared solder joint comes into contact with the solder nozzle. The flux applied to other points is not burnt and remains untouched. Soldering defects do not usually occur with this process. Nevertheless, there are two major problem areas when applying the flux: the XY positioning of the dispenser and the possible formation of crystals at the fluxer nozzle - in both cases, the flux can be applied at the wrong point. This can lead to insufficient or no flux being applied to the solder joints, resulting in poor and therefore unreliable solder joints. Unactivated flux can also creep under sensitive circuit elements, leading to faults or failures that are difficult to localize.

Soldering technology

SolderStar has spent more than six months researching and testing this problem with various flux mixtures, which showed a wide range of results. A special sensor made of high-temperature thermoplastic material was developed as a solution to the problem. It contains a resistance sensor with a stainless steel surface. The configurable measuring system based on this can be adapted for different types of flux.

Selective soldering - the best method?

Basically, selective soldering technology is based on various known processes and methods, but its greatest advantage is the targeted soldering of individual components and the targeted application of flux. This makes selective soldering a very effective process. Selective soldering of wired components and power components offers some fundamental advantages over conventional processes such as wave soldering, as the thermal shock experienced by the sensitive assemblies and components in the wave is fundamentally avoided.

It is basically a flexible and therefore easily adaptable process that is suitable for many critical soldering tasks. With the SolderStar monitoring system for selective soldering processes, the user has a measuring instrument for setting up machines and processes and for optimally adjusting the soldering systems. The soldering process can also be checked quickly and efficiently at any time during production. This means that even high production requirements can be met. Selective soldering technology has proven to be the right answer to a whole range of challenges in the soldering process in electronics production. For example, circuit design is becoming increasingly complex, but the assemblies must be produced reliably despite the associated critical aspects of production technology. Selective soldering of assemblies is now a standard procedure in many electronics production lines. In particular, the process is used for assemblies that have to be manufactured and soldered with the highest precision and reliability. This is one of the reasons why this soldering method is currently undergoing continuous development and is on its way to being implemented as the most important process option for critical and sensitive assemblies in production lines.