The Garz & Fricke Group, a specialist in human machine interfaces, single board computers and embedded innovations, has replaced parts of its SMD production line with a Fuji NXT III in recent months.

Overall picture of the new assembly lineTheprinted circuit board is the central 'brain' of the embedded systems and human machine interfaces (HMIs) that have made the Garz & Fricke Group one of the European market leaders in its segment. They are designed and manufactured in-house at Garz & Fricke - i.e. equipped with various electronic components such as resistors, capacitors, integrated circuits (IC) for specific tasks such as WLAN or Bluetooth as well as connectors for inputs and outputs. The placement is carried out by automatic placement machines as part of the SMD production line.

Overall picture of the new assembly lineTheprinted circuit board is the central 'brain' of the embedded systems and human machine interfaces (HMIs) that have made the Garz & Fricke Group one of the European market leaders in its segment. They are designed and manufactured in-house at Garz & Fricke - i.e. equipped with various electronic components such as resistors, capacitors, integrated circuits (IC) for specific tasks such as WLAN or Bluetooth as well as connectors for inputs and outputs. The placement is carried out by automatic placement machines as part of the SMD production line.

The new placement machines were necessary for several reasons. After years of using the existing systems, disadvantages such as the two-sided and sometimes non-ergonomic operation became apparent. Above all, however, the machines were no longer up to date. For example, it was no longer possible to handle the current tiny sizes of the electronic components.

Another decisive reason: "The old line was made up of different generations of machines that were due to be discontinued. This means that support will be discontinued soon," explains Christian Gillmann, Coordinator of PCB production. For Garz & Fricke, which produces around 250,000 boards per year, this was an absolute no-go. After all, with the end of support for the machine, the availability of spare parts is no longer guaranteed and, in the worst-case scenario, a defect would result in a long-term system failure. At the end of 2017, it was clear that a new machine was needed.

How a pick and place machine works

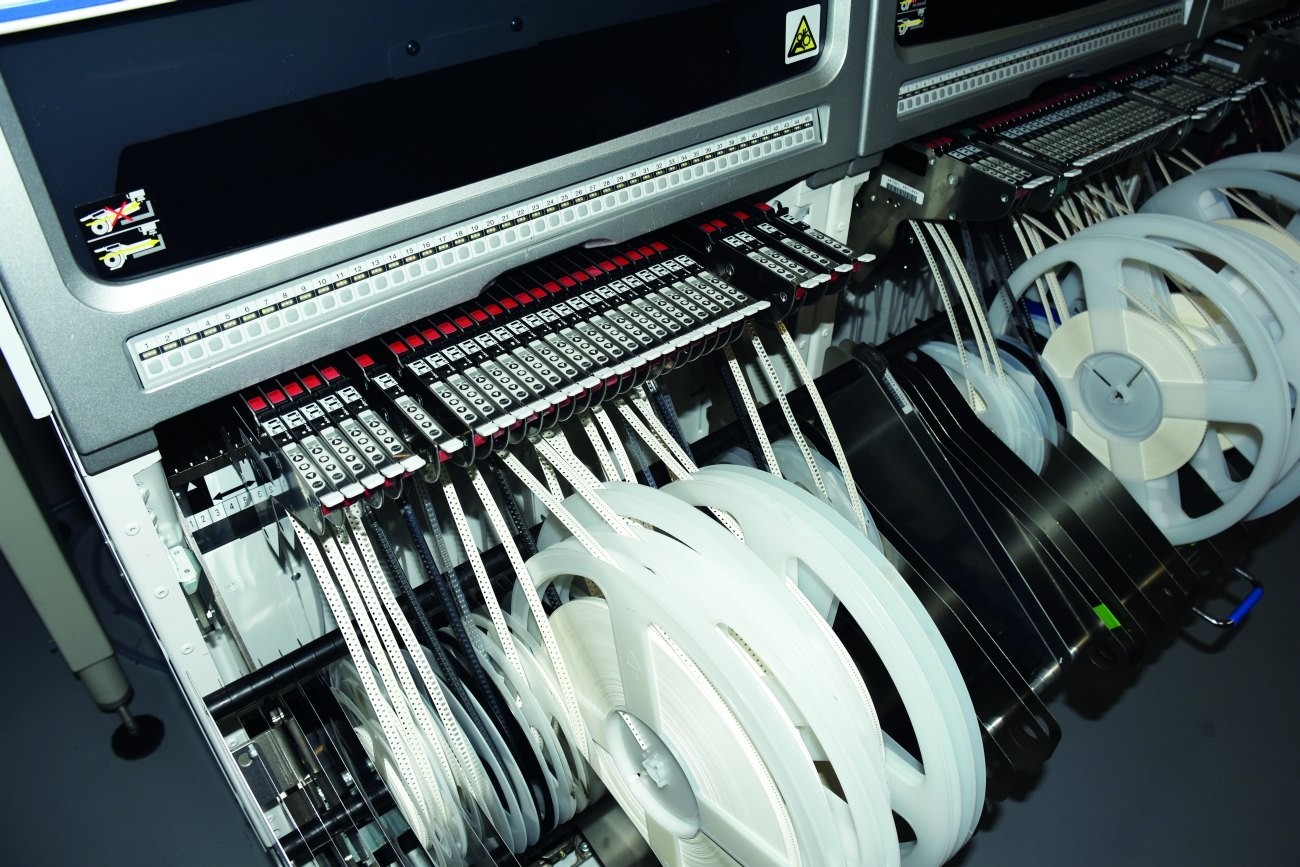

In pick-and-place machines, a conveyor belt runs in the middle of the system, on which the circuit board is placed as a blank. The components are placed on the conveyor belt according to the pre-programmed X, Y and Z coordinates and a defined rotation angle in the solder paste that has already been applied. The components themselves are fed via special belts, the blisters, which are inserted into the feeder in rolls.

The feeders pull the components into the machine via the belt and place them in a defined position. The placement heads suck in the component by vacuum and place it precisely on the PCB. With older machines, such as the one that was replaced at Garz & Fricke, employees had to check that everything was set up correctly using the four-eyes principle. Modern systems are able to check automatically - for example, using integrated high-resolution cameras and image recognition - whether the correct component is where it should be. Thanks to the new system, Garz & Fricke can now install the smallest components down to 0.25 x 0.125 mm. However, the significantly larger odd-shape components are also a particular challenge when assembling PCBs. Not only do they measure up to 50 x 30 x 25 mm, they are also often hooked into the board. Classic RJ45 sockets are one example: when inserted into the board, a barb is pressed together and snaps open when correctly positioned. The component is then firmly anchored. However, the system has to apply a certain amount of force for this process, the so-called latching torque. The old system was unable to apply this torque reliably. With the new system, engaging is now problem-free. "We can apply defined forces with the system up to a certain point."

Family armor

Detail: Blister rolls in the feederNotonly does the new machine in Hamburg work much more precisely and reliably, it also enables the Garz & Fricke Group to implement long-awaited production concepts. A so-called family setup can now be implemented. The machine is equipped with the most commonly used components throughout. On average, a single board computer consists of 140 items, which are distributed across the placement positions. The new system can memorize significantly more than 700 positions.

Detail: Blister rolls in the feederNotonly does the new machine in Hamburg work much more precisely and reliably, it also enables the Garz & Fricke Group to implement long-awaited production concepts. A so-called family setup can now be implemented. The machine is equipped with the most commonly used components throughout. On average, a single board computer consists of 140 items, which are distributed across the placement positions. The new system can memorize significantly more than 700 positions.

The operators can add individual or special elements to each board. This makes it possible to deliver tailor-made, customer-specific solutions even more flexibly on the basis of a modular system. "Before we switched to the new system, we sometimes had days when we only produced one side of a board. Then the machine was retooled for the other side. As a result, we were unable to pass on finished single board computers to subsequent processes - such as testing - on the first day of this order batch," explains Gillmann. "With the new system, we can bring a complete batch of single board computers in a smaller batch size to the test stage within one shift." This means that these boards are available for assembly the very next day. With a throughput time of one day in PCB production, Garz & Fricke can now serve customers in the shortest possible time. "That was one of the main requirements for the new system."

Small series capabilities

At the same time, small series can now be produced at any time, which were previously not feasible in terms of batch size. This small-batch production is made possible by the continuous production feature: the program can be changed seamlessly so that the PCBs for board B are already being fed into the front section while board A is still being assembled in the rear section. The transition between the boards is seamless. Christian Gillmann: "We also requested this in the specifications - it's called 'seamless changeover'".

Production on the new machine is also seamless when it comes to replenishing empty blister rolls. If the supply of a component runs out, the operator receives information such as component XY will be empty in six minutes on large information screens above the machine. This allows the operator to prepare the next roll and arrive at the machine with it in good time. If the machine is fully loaded with different blister rolls, production downtime is kept to a minimum. If not all of the loading stations are in use, the new reel with components can be inserted directly into one of the empty stations during production. The system then switches seamlessly from one blister roll to the next. Production downtime is completely avoided.

The new placement machine gives operators more freedom thanks to smart networking. This is because the system not only displays messages and warnings on the aforementioned screens, but also sends the information directly to the operator. The operator wears a smartwatch on their wrist and is notified of incoming messages from the machine via vibration.

Modular, expandable, future-proof

The SMD line with its new placement machine currently extends over 18 meters in length and has a modular design. This means that the system can be completely modified by the company's own technicians. Modules can be removed and integrated into other production lines. The current installation can also be continuously expanded.

The placement heads inside the system are just as flexible as the system itself. If their performance is no longer sufficient, such a head can easily be replaced with a more powerful one. It is also possible to use heads with special capabilities, e.g. adhesive heads that apply a so-called SMD adhesive. The exchange is possible from production to production. This means that the machine can be adapted to new requirements in the future, which are not yet being discussed today.

Another decisive difference to the old system is the spatial concept. On the old system, the operators had to move to both long sides to check and replenish blister rolls. With the new system, everything happens on just one side, so that the operator only has to monitor a six and a half meter long front. The system can also be positioned closer to the hall wall, which creates space for additional machines and production options.

Handling & support

It took almost three years of planning to realize the new machine - with support from Fuji Europe Corporation in clarifying many detailed questions and adapting the machine and software technology. Garz & Fricke is now well equipped for the coming years. After all, the Hamburg specialists guarantee their customers that the single board computers will be available for a decade. This and the shortest delivery times are assured with the new system. In addition, the new system enables a completely new type of traceability of the components used: Garz & Fricke can document production down to the individual blister roll. In the event of a defective component delivered by a supplier, traceability is now ensured right down to component level.