The use of sensors is becoming increasingly important in many areas of industry. These should be integrated into existing devices wherever possible without affecting their form factor. Developers are faced with major challenges, especially in highly miniaturized applications, as the existing volume is already used efficiently and there is often no space available for integrating sensors using conventional methods.

Additive manufacturing processes are becoming increasingly important: they allow functionalities to be integrated in the smallest possible way. The Cicor Group develops customer-specific printed electronics applications and sensors using the aerosol jet printing process. The process developed by Optomec has significant advantages over standard inkjet processes in terms of the achievable resolution of the printed structures. The inks used are atomized using either a pneumatic or an ultrasound-based process, creating an aerosol in which the droplet size is between 1 and 5 μm. Nitrogen is typically used as the carrier gas. The choice of atomization method is based on the specific properties of the ink to be processed. There is a large selection of inks for printed electronics applications; if the viscosity and particle size are within the target range, they can most likely be printed using aerosol jet technology.

Depending on the print head size selected, the structure widths that can be achieved are between 10 μm and 1 mm in one print run. If required, wider conductors can also be printed, in which case parallel lines are printed that overlap. The same applies to very high precision requirements, where it is advantageous to work with smaller print head diameters, as this achieves a more precise contouring of the structures. The thickness of the layers is between a few 100 nm and 10 μm; if larger values are required, several layers of material can be deposited on top of each other. The layers are cured either using thermal methods or, in the case of non-conductive materials, with UV light.

There are 2 possible solutions for the integration of sensors. Either they are printed directly onto the component or the technology is used to connect a sensor. In both cases, it is possible to integrate the supply lines to the components into the printing process.

In the following, we will introduce you to variants of printed sensors and also discuss application examples.

Chemical sensors

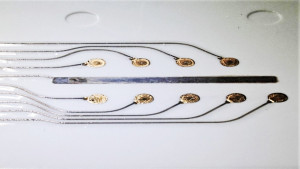

Fig. 1: Chemical electrode array printed with biocompatible gold ink; Image: Cicor GroupChemicallyinert gold and platinum inks as well as carbon materials are available that can be printed as electrode surfaces. The subsequently applied reactive substances interact with the solution to be tested to generate a measurement signal that is transferred via the electrodes without falsifying it by releasing ink components. These layers can be applied to a wide variety of carrier materials. One possible application is, for example, the printing of such sensors in microfluidic channels, which are typically used for measurements in medical technology and bioanalytics. If silver or copper inks are used instead of chemically inert materials, for example, these can be used as corrosion sensors. The resistance values changed by the effects of harmful gases provide information about the condition or remaining service life of systems and devices.

Fig. 1: Chemical electrode array printed with biocompatible gold ink; Image: Cicor GroupChemicallyinert gold and platinum inks as well as carbon materials are available that can be printed as electrode surfaces. The subsequently applied reactive substances interact with the solution to be tested to generate a measurement signal that is transferred via the electrodes without falsifying it by releasing ink components. These layers can be applied to a wide variety of carrier materials. One possible application is, for example, the printing of such sensors in microfluidic channels, which are typically used for measurements in medical technology and bioanalytics. If silver or copper inks are used instead of chemically inert materials, for example, these can be used as corrosion sensors. The resistance values changed by the effects of harmful gases provide information about the condition or remaining service life of systems and devices.

Capacitive sensors

Due to the flexibility of aerosol jet technology, conductive structures can be applied to a wide variety of materials. The technology is ideally suited for the production of capacitive sensors. These can be printed on the inside of housings, for example, and thus enable devices to be operated without having to accommodate additional components. If such sensors are printed in devices that need to be waterproof, the risk of liquids getting into the device is reduced. The integration is seamless and there are no weak points, such as gaps or seals, through which moisture can penetrate.

Another option is to use the printed structures as proximity sensors so that the device recognizes whether it is being worn on the body or not, for example. This function can be used for medication dosage systems such as insulin pumps.

Fig. 2: Circuit printed on the inside of a plastic housing with integrated capacitive switches and wipe sensors; image: Covestro

Fig. 2: Circuit printed on the inside of a plastic housing with integrated capacitive switches and wipe sensors; image: Covestro

Temperature sensors

Two different options are available for temperature sensors. Either so-called thermistor inks are used, where the measuring principle is based on the temperature-related change in resistance of the conductor structures. Or two metal inks are printed, in which case the thermoelectric effect is used. Possible applications here include permanent measurement of body temperature, measurement in the area of wounds or monitoring the storage conditions of medicines.

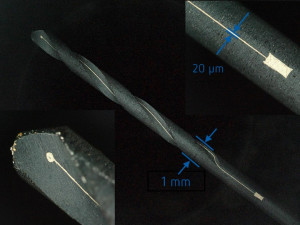

If the sensors are printed on medical devices such as drills, for example, temperature monitoring can prevent overheating and the associated tissue damage.

Bending, strain and force sensors

If special inks that change their resistance when stretched or bent are used, they can be used in areas where these loads need to be monitored. To measure dynamic forces or strains, it is possible to apply piezo inks between two electrodes and measure local changes using the electrical signal generated. If these strain sensors are pressed onto implants, for example, the measurement signals can be used to determine whether they are exposed to mechanical stress in the body. This can have a negative impact on the healing process or prevent the desired end result from being achieved.

Embedded sensors

An additional option is to connect embedded semiconductor or chip-based sensors. These can, for example, be positioned directly in the mold and then back-injected with plastic. The connection can then be made directly via aerosol jet pressure. Compared to conventional soldering processes, the temperature load on the sensors is significantly lower and allows them to be connected gently.

Summary

Due to its flexibility, aerosol jet technology offers a wide range of options for integrating sensors into a wide variety of electronic devices, whether by connecting sensor components or by directly printing special functional inks. The possible uses extend across a wide range of applications in all industry segments. This applies to highly miniaturized devices in the medical sector through to applications that are exposed to challenging environmental conditions. New inks are constantly being developed whose properties are precisely tailored to the respective area of application. If the viscosity of these materials is within the specified range and the particle size does not exceed a certain level, it is highly likely that they can be processed using the aerosol jet printing process. The various curing and sintering methods enable their functionalization on a broad portfolio of carrier materials. Close cooperation between the user and the future manufacturing partner is essential during product development in order to make the best possible use of the opportunities offered by this technology.