The important topic of sustainability affects all industries. The electronics industry is also required to further reduce itsCO2 footprint by saving energy and choosing appropriate materials and consumables. Balver Zinn is also facing up to this challenge.

For energy-efficient selective and reflow soldering, Balver Zinn offers low-melting solders such as SnBi28 and BSA04. Special attention is also paid to the use of secondary material. By using the innovative SnBi28 alloy, the solder bath temperatures in selective systems can be reduced by around 50 K with equivalent or better soldering results, thus saving the user energy.

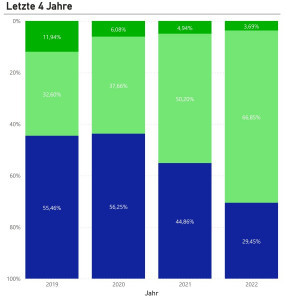

Fig. 1: Percentage material usage of pure tin at Balver Zinn in the period 2019-2022Thelow-melting alloy SnBi28 complements the variety of alloys in the JEAN-151 solder paste product range, which is now available in 9 different alloys. The wide range of variants of the JEAN-151 solder paste, the large process window and the robustness ensure the market success of the solder paste family.

Fig. 1: Percentage material usage of pure tin at Balver Zinn in the period 2019-2022Thelow-melting alloy SnBi28 complements the variety of alloys in the JEAN-151 solder paste product range, which is now available in 9 different alloys. The wide range of variants of the JEAN-151 solder paste, the large process window and the robustness ensure the market success of the solder paste family.

As part of theCO2 reduction programme, Balver Zinn has also optimized its portfolio of cleaners and the REGI flux series. The majority of the cleaners are now water-based. And with REGI-BLUE, a reliable water-based flux is now available.

Balver Zinn has successively reducedCO2 emissions in the use of metals, solvents and auxiliary and operating materials. In recent years, the use of primary materials for pure tin has been continuously reduced. By using secondary tin, around 80% ofCO2 can be saved compared to primary material.

Around a third of the fluxes sold by Balver Zinn are partially water-based (low-VOC), which equates to around 35% lessCO2 emissions in direct comparison to alcohol-based products. The sales figures for the newly implemented, water-based REGI-BLUE suggest that this trend will continue.

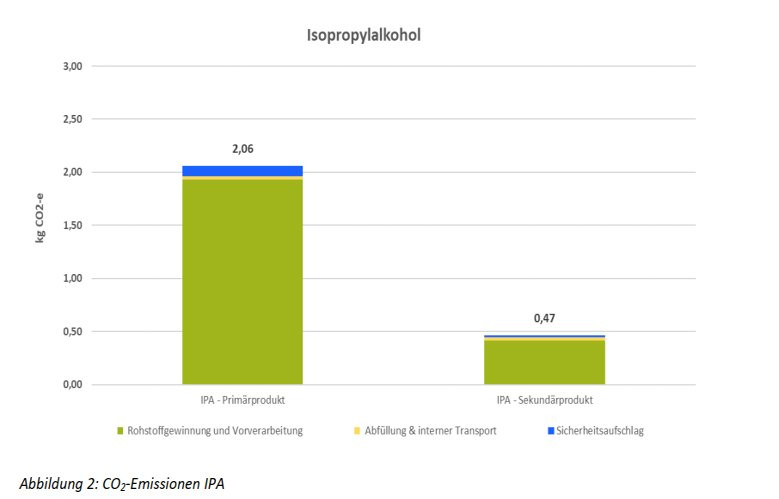

The use of secondary isopropanol (IPA) instead of primary IPA is currently being examined. This will enable a further 75%reduction in CO2 emissions. With more energy-efficient lighting, the gradual conversion of the vehicle fleet to electric vehicles and the recently completed switch to new burner technologies (< 25%CO2 emissions), Balver Zinn has also optimized its operating facilities. The planned switch from natural gas to propane in the near future will make it possible to maintain security of supply through local sources and save even more energy thanks to the higher calorific value of propane.

Fig. 2:CO2 emissions for the production of IPAIn order tofurther increase customer satisfaction, fast, precise and efficient inquiry and ordering processes at Balver Zinn are being remapped and further expanded. It will soon be possible to order products directly from the website using intuitive online systems. Through online stores such as 'Fischer Leiterplattentechnik' and 'Technisches Büro Kullik', Balver Zinn offers flexible sources of supply so that products can also be ordered outside of opening hours.

Fig. 2:CO2 emissions for the production of IPAIn order tofurther increase customer satisfaction, fast, precise and efficient inquiry and ordering processes at Balver Zinn are being remapped and further expanded. It will soon be possible to order products directly from the website using intuitive online systems. Through online stores such as 'Fischer Leiterplattentechnik' and 'Technisches Büro Kullik', Balver Zinn offers flexible sources of supply so that products can also be ordered outside of opening hours.