Stencils for SMD solder paste printing are an indispensable part of electronics production. The stencil must not only meet a wide range of quality requirements, it must also be quick and easy for the user to determine and obtain. This is now possible via an online store.

SMD printing stencil of the 'Basic Plus' version "Precise SMD printing stencils for the shortest production deadlines is our business," emphasizes Axel Meyer, Head of Sales and Marketing at Photocad GmbH in Berlin. The time from receipt of the customer's order to dispatch of the customized SMD stencils is therefore usually just a few hours - in other words, "on the fast track."

SMD printing stencil of the 'Basic Plus' version "Precise SMD printing stencils for the shortest production deadlines is our business," emphasizes Axel Meyer, Head of Sales and Marketing at Photocad GmbH in Berlin. The time from receipt of the customer's order to dispatch of the customized SMD stencils is therefore usually just a few hours - in other words, "on the fast track."

This would not be possible without comprehensive digitalization of all processes. This begins as soon as the order is received: the Berlin-based company receives the data for the production of an SMD stencil by email or directly via the online store. The data is 'processed' by qualified employees at the CAD stations in the work preparation department.

The checked and validated data is then forwarded directly to one of the three prepared LPKF G 6080 production laser machines and produced in-house. The finished SMD stencils are then checked digitally using StencilCheck, also from LPKF.

As soon as the order is received, the complete commercial processing and production planning is carried out in parallel with the in-house ERP/PPS system Beosys 9. And shipping is digitally connected to the logistics provider UPS with the WorldShip software. This enables customers to track their ordered SMD stencils promptly. All orders are stored completely digitally in the cloud with the ELO software, so that this data can be accessed at short notice in the event of queries, change requests, repeat orders, etc.

Continuous further development for 15 years

Photocad launched its first online store back in 2005 and after various further development steps, powerful tools were added in the form of the 'Product Advisor' and 'Configurator' modules - the overall system became "probably the most professional online order entry and production option in the German-speaking world", according to Meyer.

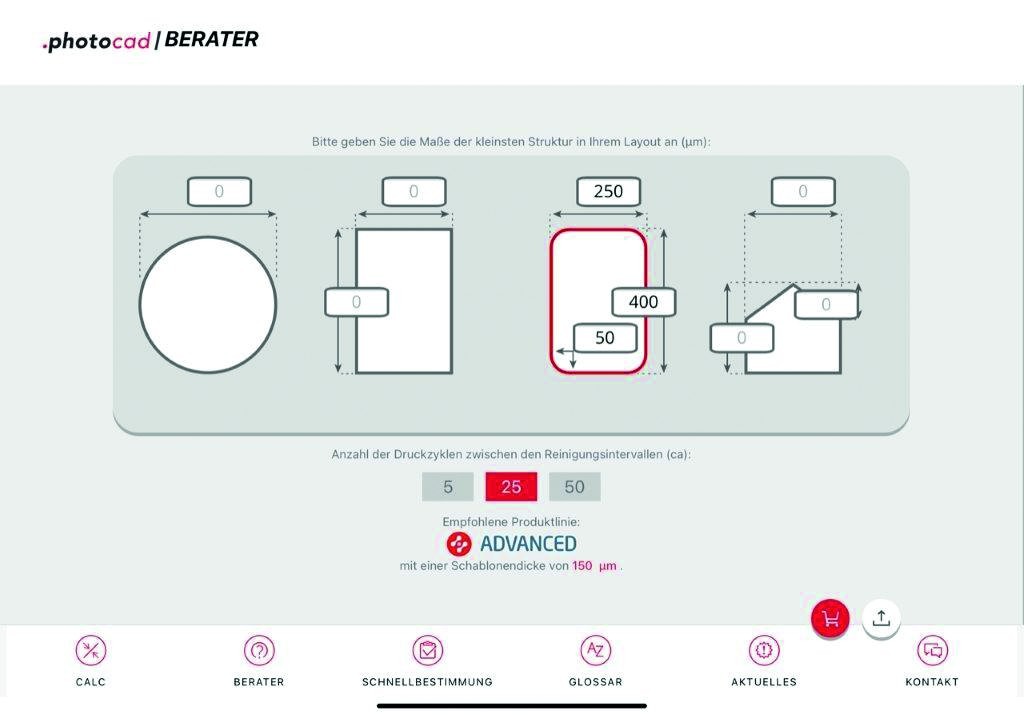

The 'Product Advisor': pre-select your own optimal SMD printing stencil with just a few clicks

The 'Product Advisor': pre-select your own optimal SMD printing stencil with just a few clicks

App for exact determination of a stencil

Automatic laser machine G 6080 inline inspectionThe'Product Advisor' app is compatible with IOS and Android and can be used on smartphones and tablets. With just a few clicks, you can create a preselection for your own optimal SMD printing stencil - for example by determining

Automatic laser machine G 6080 inline inspectionThe'Product Advisor' app is compatible with IOS and Android and can be used on smartphones and tablets. With just a few clicks, you can create a preselection for your own optimal SMD printing stencil - for example by determining

- the stencil thickness

- the smallest opening dimension

- the printing cycles between cleaning intervals.

Since 2020, the 'Product Advisor' has been equipped with additional up-to-date features: in dark mode, the display is not only glare-free, but can also be used in darkened areas. The new user interface makes operation very easy and ensures precise calculation of, for example, the thickness, openings or number of printing cycles of the SMD printing stencil. Customers gain security and time even before placing an order - free of charge and without obligation. If Photocad actually receives the order, the information from the product advisor is transferred to the 'Configurator' for further production and order processing steps, saving time and eliminating errors.

The customer uses this to order their customized SMD printing stencil in different versions according to their specifications:

- as a 'functional sample' for a new project

- as 'Basic Plus' for the quick standard

- as 'Advanced' for the smallest components

- as 'Performance' for maximum performance with additional information for electropolishing or nano-finishing to increase the number of printing processes and reduce cleaning intervals, or

- as a 'step stencil' for specific requirements

In the 'configurator', the customer also digitally determines their specific information such as format details with clamping system, material, surfaces, stencil layout, number of pads and options for packaging or 'same-day delivery' to Germany, Austria and Switzerland. According to the Head of Sales and Marketing, Photocad is constantly monitoring specific customer requirements in order to analyze them precisely and enable the customer to determine the technical specifications of the SMD stencil and the ways in which it can be obtained to meet their exact requirements. Meyer: "Our motto in this respect is 'Precision that works'."